A kind of active inorganic anti-corrosion coating for improving the bond strength between steel bar and concrete and its coating method

A technology of bonding strength and anti-corrosion coating, applied in the direction of anti-corrosion coatings, surface pretreatment bonding methods, coatings, etc., can solve problems such as personnel and property losses, and achieve high bonding strength, high adhesion, and construction various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

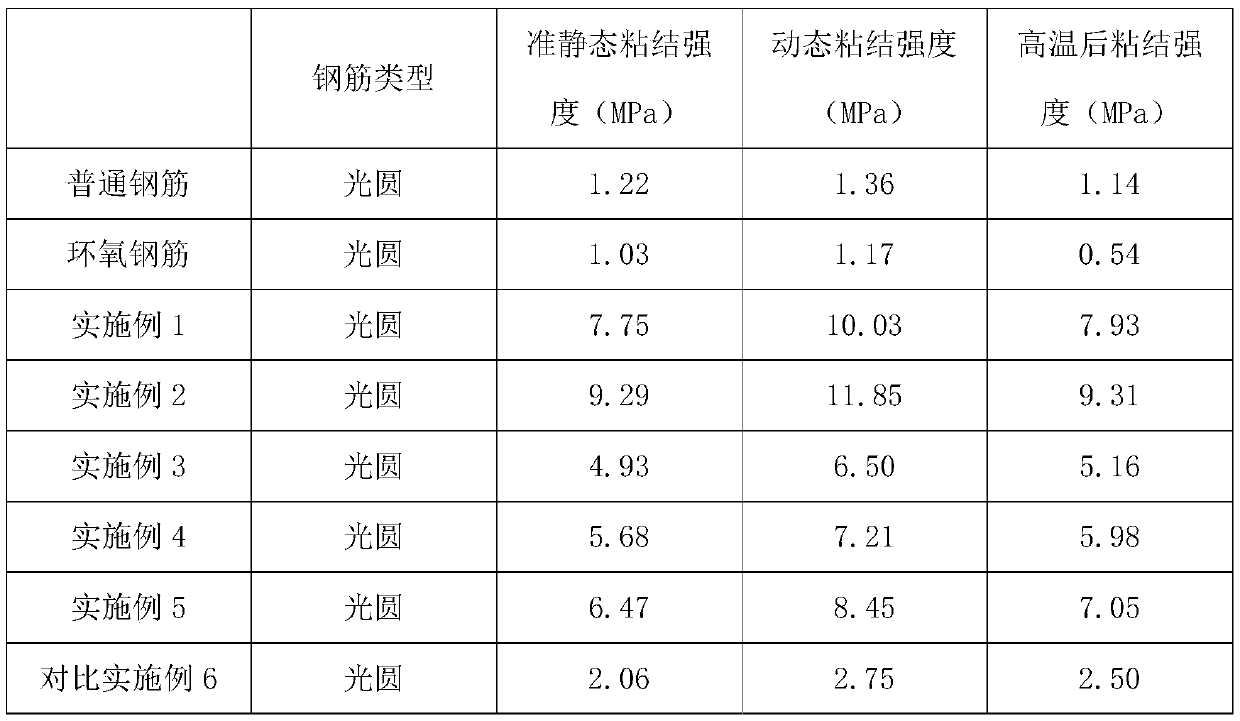

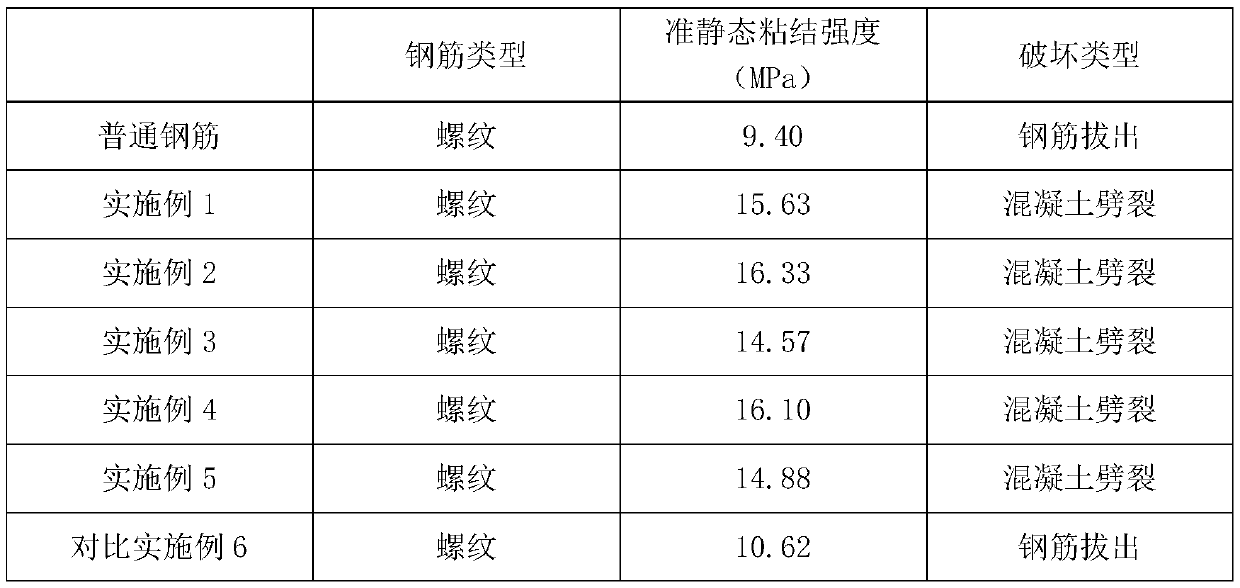

Examples

Embodiment 1

[0030] An active inorganic anti-corrosion coating for improving the bond strength between steel bars and concrete, the raw materials include the following components by weight: 165g of phosphorus pentoxide; 100g of nano silicon dioxide; 90g of aluminum oxide; 12g of potassium carbonate, oxidized 22.5g of boron, 34g of sodium carbonate; 4g of nickel monoxide, 7.5g of cobalt monoxide; 15g of dicalcium silicate, 25g of tricalcium silicate, 25g of tricalcium aluminate; wherein said dicalcium silicate, tricalcium silicate, Tricalcium aluminate passed through a 400-mesh sieve.

[0031] A method for coating an active inorganic anti-corrosion coating for improving the bonding strength between steel bars and concrete, comprising the following steps:

[0032] 1) Preparation of coating: Weigh 165g of phosphorus pentoxide, 100g of nano-silicon dioxide, 90g of aluminum oxide, 12g of potassium carbonate, 22.5g of boron oxide, 34g of sodium carbonate, 4g of nickel monoxide, 7.5g of cobalt mo...

Embodiment 2

[0040] An active inorganic anti-corrosion coating used to improve the bonding strength between steel bars and concrete. The raw materials include the following components by weight: phosphorus pentoxide 100g; silicon dioxide 100g, quartz 75g; alumina 25g, nano-alumina 25g; potassium carbonate 16g, boron oxide 40g, chromium oxide 2.5g, vanadium oxide 17.5g, tungsten oxide 5g; nickel trioxide 5g, cobalt monoxide 9g; calcium oxide 15g, calcium silicate 65g; Silicon, quartz, calcium oxide, and calcium silicate pass through a 400-mesh sieve.

[0041] A method for coating an active inorganic anti-corrosion coating for improving the bonding strength between steel bars and concrete, comprising the following steps:

[0042] 1) Preparation of coating: Weigh 100g of phosphorus pentoxide; 100g of silicon dioxide, 75g of quartz; 25g of alumina, 25g of nano-alumina; 16g of potassium carbonate, 40g of boron oxide, 2.5g of chromium oxide, 17.5g of vanadium oxide, tungsten oxide 5g; 5g of nic...

Embodiment 3

[0049] An active inorganic anti-corrosion coating used to improve the bond strength between steel bars and concrete. The raw materials include the following components by weight: 140g of phosphorus pentoxide; 70g of nano-silicon dioxide, 50g of silica; 60g of nano-alumina; Boron 40g, sodium carbonate 11.5g, vanadium oxide 2.5g, nickel monoxide 2.5g; dicobalt trioxide 5g; dicalcium silicate 12.5g, tricalcium silicate 75g, tricalcium aluminate 22.5g, tetracalcium aluminoferrite 8.5 g; wherein the silica, dicalcium silicate, tricalcium silicate, tricalcium aluminate, and tetracalcium aluminoferrite pass through a 400-mesh sieve.

[0050] A method for coating an active inorganic anti-corrosion coating for improving the bonding strength between steel bars and concrete, comprising the following steps:

[0051] 6) Preparation of coating: Weigh 140g of phosphorus pentoxide; 70g of nano-silicon dioxide, 50g of silica; 60g of nano-alumina; 40g of boron oxide, 11.5g of sodium carbonate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com