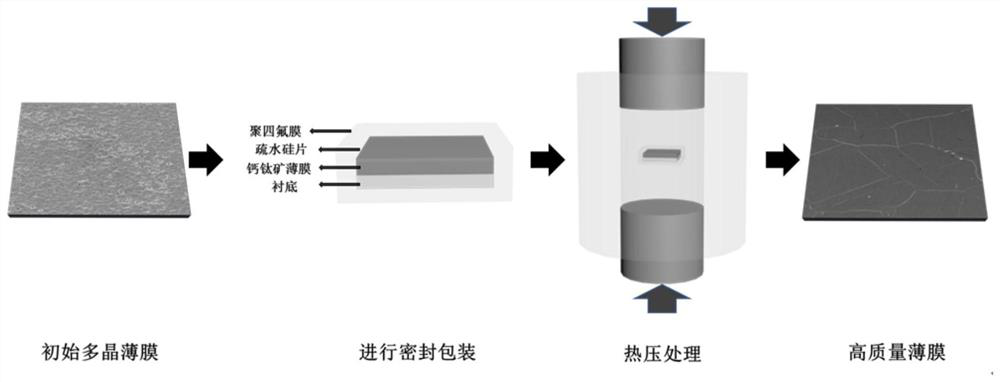

A pressure-driven ion diffusion growth method for the preparation of inorganic perovskite single crystal thin films

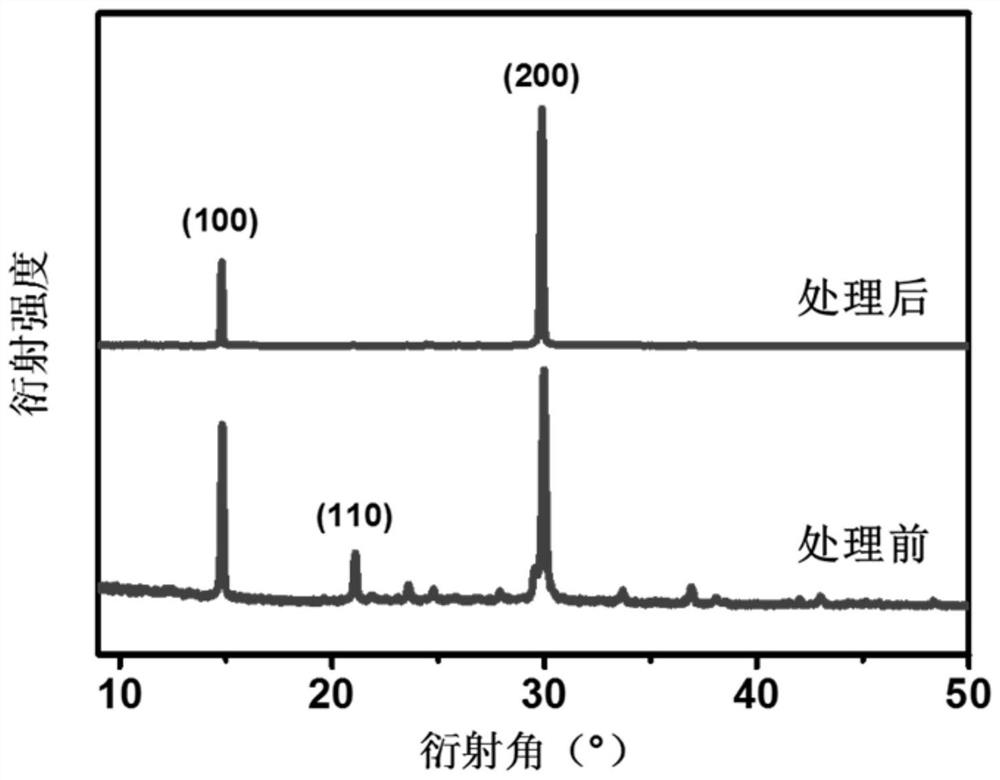

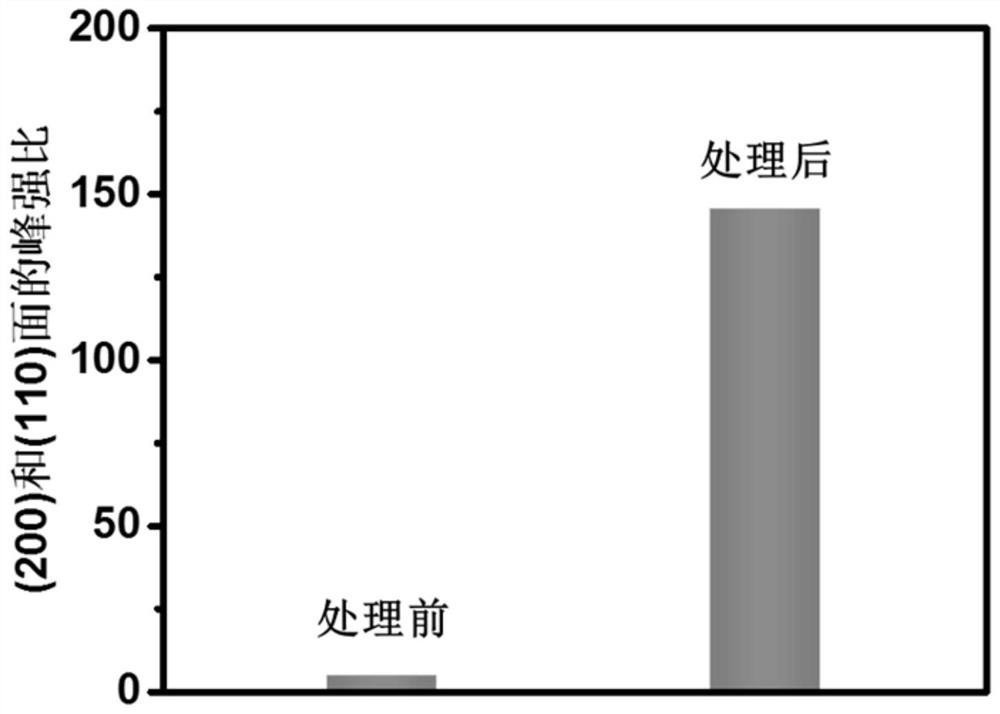

A single crystal thin film, ion diffusion technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high heat treatment temperature, film damage, and the inability to realize the secondary growth of grains, etc., to achieve uniform film layer, Improving performance and eliminating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A pressure-driven ion transport growth method for preparing an inorganic perovskite single crystal film, comprising the following steps:

[0041] 0.21 mmol PbBr 2 with 1.19 mmol PbI 2 Dissolve in 1mL of DMF / DMSO mixed solution and stir at room temperature for 3h, then filter with a 0.22μm pore size filter; place the surface-cleaned ITO glass on a hot stage at 70°C for 5min, then add 40μL of the above mixed solution dropwise Added to the ITO glass substrate and spin-coated at 2000 rpm for 30s. The films thus obtained were annealed at 70°C for 5 min. Next, a certain amount of CsBr was dissolved in 0.98 mL of methanol to obtain a CsBr solution with a concentration of 15 mg / mL, and then 0.02 mL of DMSO was added to the CsBr solution to obtain a CsBr precursor solution. Add one drop of the CsBr precursor solution (approximately 10 μL) to the PbI prepared above 2 / PbBr 2 surface of the film, and rotate at a speed of 2500 rpm until the solvent evaporates. T...

Embodiment 2

[0048] Example 2: A method for preparing an inorganic perovskite single-crystal thin film by pressure-driven ion diffusion growth. The operation steps are the same as in Example 1, except that the polished cover sheet is replaced with a polished glass sheet, and the heat and pressure transfer medium It is triethylene glycol, the hot-pressing pressure is 25MPa, the hot-pressing temperature is 300°C, the hot-pressing time is 60 hours, the heating rate is 5°C / min, and the treated film is CsPbBr 3 .

Embodiment 3

[0049] Example 3: A method for preparing an inorganic perovskite single crystal thin film by pressure-driven ion diffusion growth. The operation steps are the same as in Example 1, except that the polished cover is replaced by a gallium arsenide single wafer, and the sample is coated with The flexible film is gold foil, the heat transfer and pressure transfer medium is triphenylmethanol, the heat treatment pressure is 500MPa, the hot pressing temperature is 100°C, the heat treatment time is 360 hours, the heating rate is 1°C / min, and the treated film is CsSnCl 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com