Recirculating prawn aquaculture method in combination with nitrification-assimilation effect

A technology of recirculating aquaculture and assimilation, applied in the direction of chemical instruments and methods, applications, fish farming, etc., can solve the problems of high energy consumption in system operation, low economic benefits, low success rate of recirculating aquaculture, etc., and achieve improved treatment Efficiency, reduction of water circulation rate, and the effect of inhibiting some potential pathogens of Flavobacteriaceae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

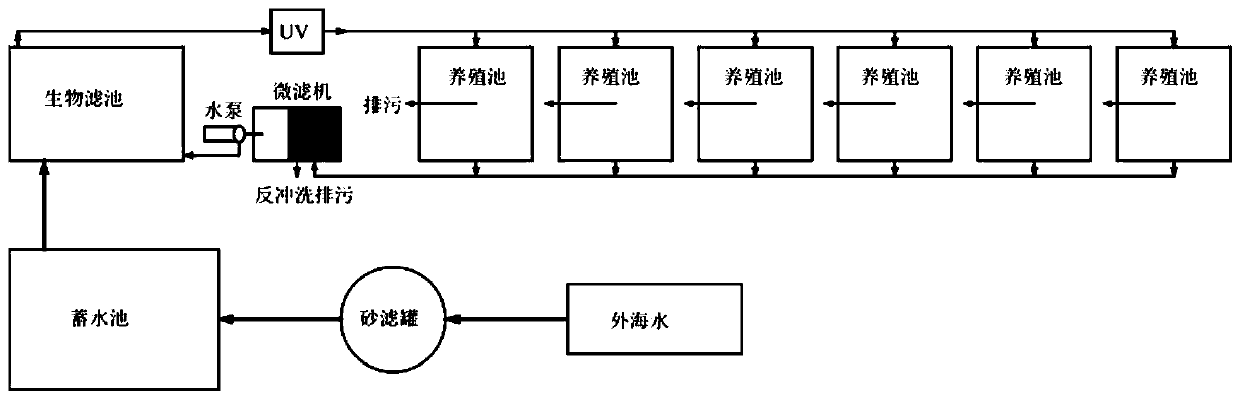

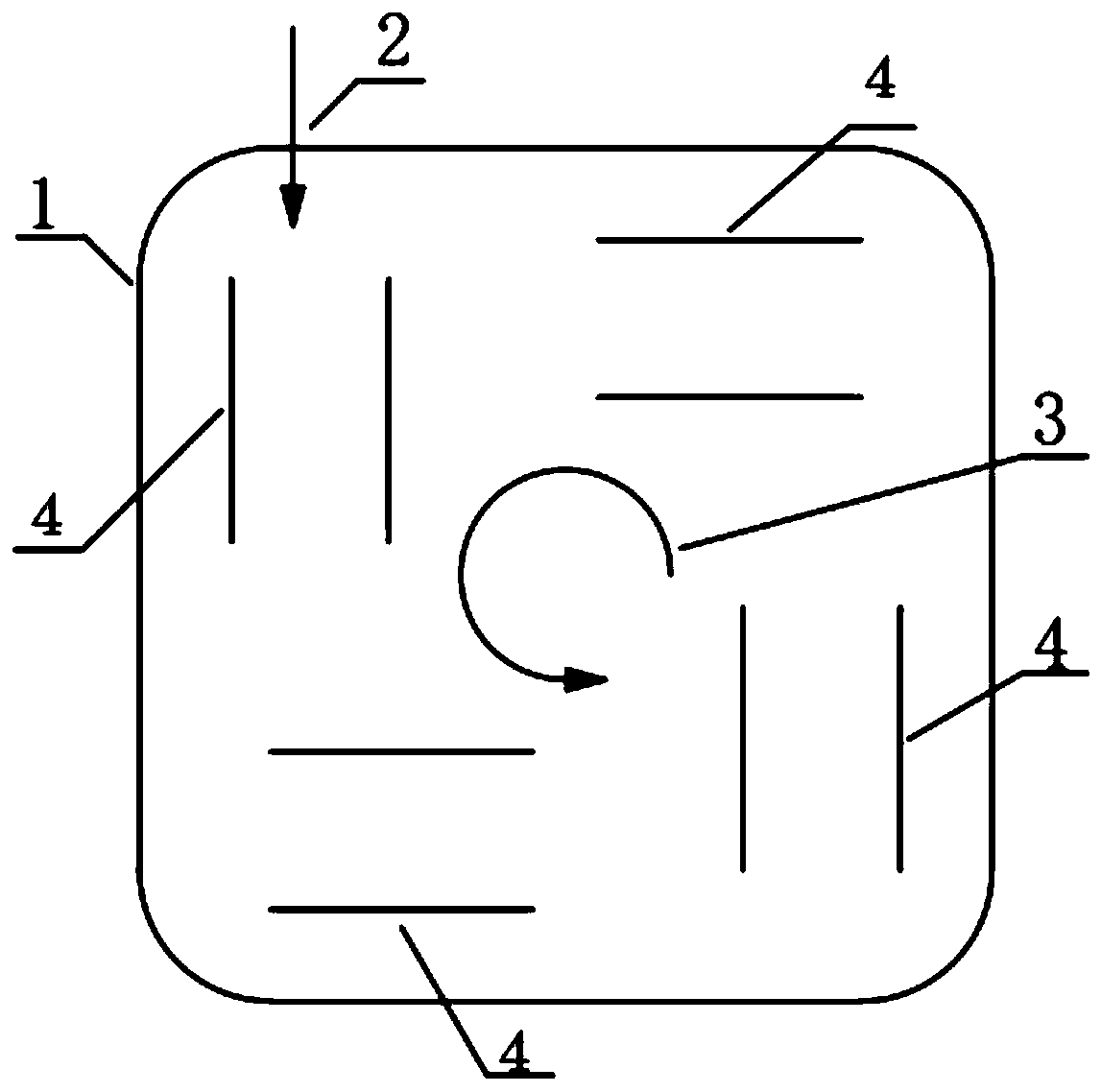

[0021] Farming systems such as figure 1 As shown, there are 6 breeding ponds with a size of 6.5×6.5m and a water depth of 0.9m; the cultivation ponds are cone-shaped and low, with a slope of 1 / 15~1 / 20, and the central sewage discharge pipe is shared with the circulating return water pipe;

[0022] Crawler-type microfilter, screen size 120 mesh, automatic backwashing according to liquid level difference; water circulation pump flow speed 25-30m 3 / h, the aquaculture pond water body circulates 2 to 3 times per day; the size of the biological filter is 7.45×3.0×2.6m, filled with elastic brush biological filter material, the filling rate is 50%, the biofilm is cultivated in advance before the system starts, and the nitrification system is constructed; The rated power of the sterilization device is 2.4kw, and the operating power is divided into four levels; the power of the inflatable Roots blower in the breeding pond is 3kw, and the nanotubes are arranged around the breeding pond and f...

Embodiment 2

[0026] The breeding system and management are the same as in Example 1. No carbon source is added during the breeding process, and the water quality is controlled by the nitrification of the biological filter and the physical filtration method. The system is operating well in the early stage of aquaculture, and the concentration of ammonia nitrogen and nitrite is controlled below 0.5mg / L; however, with the growth of prawns, the amount of feed is greatly increased, and the water treatment load of the system increases, and the ammonia nitrogen and nitrous acid in the later stage of aquaculture The salt concentration gradually increased, the concentration of ammonia nitrogen reached 3.1mg / L and the concentration of nitrite reached 5.4mg / L at the end of aquaculture, threatening the healthy cultivation of prawns. After 65 days, the prawn farming load is 2.8kg / m 2 .

Embodiment 3

[0028] The breeding system and management are the same as in Example 1. No carbon source is added during the breeding process, and the breeding water environment is regulated by increasing the system water circulation and strengthening the nitrification of the biological filter. The system water circulation rate is 10-15 times / day. During the breeding process, water quality indicators such as ammonia nitrogen and nitrite are well controlled and the aquaculture water is clear, but it is not suitable for Litopenaeus vannamei breeding. The diversity of colony in the aquaculture water is low. In the structure of the colony, the Pseudoalteromonas family accounts for 32.63% of the total number of bacteria, Colwell's family accounts for 26.24% of the total number of bacteria, and Alteromonas family accounts for the total number of bacteria. Rhodobacteraceae, which has more beneficial bacteria, did not form a dominant position, accounting for only 15.63% of the total bacterial count. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com