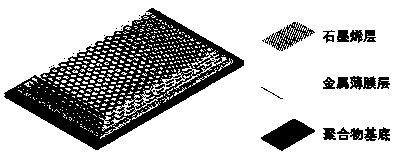

Preparation method of efficient and stable ultra-thin flexible terahertz shielding material

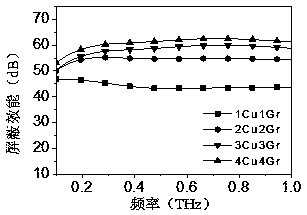

A shielding material, terahertz technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of in-depth research on flexibility stability, insufficient shielding efficiency, and less research, and achieve excellent comprehensive performance and good flexibility. and bending fatigue resistance, high shielding effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) The 30 μm thick copper foil was cleaned with deionized water, acetone, and ethanol in sequence, and then placed in a tube furnace. Under the protection of argon (500 sccm), the temperature in the furnace was raised to 1000 °C, and then hydrogen gas (20 sccm) was introduced for annealing for 40 min, and then methane (6 sccm) was introduced as a carbon source to grow graphene, and the growth time was After 13 minutes, stop feeding methane, and cool down naturally in argon and hydrogen.

[0040] (2) Spin-coat a layer of PMMA film on the surface of copper foil grown with graphene as a transfer medium.

[0041] (3) Copper foil with CuSO 4 / HCl etchant (200 g / L CuSO 4 Mixed with concentrated hydrochloric acid 1:1) to remove, leaving the graphene supported by PMMA film, and washed with deionized water repeatedly 5 times.

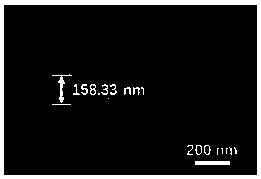

[0042] (4) Deposit a 40 nm thick copper film on the polyimide (PI) substrate by vacuum evaporation (deposition rate 0.1 nm / s, VZZ-400 high vacuum resi...

Embodiment 2

[0049] (1) The 20 μm thick copper foil was cleaned with deionized water, acetone, and ethanol in sequence, and then placed in a tube furnace. Under the protection of argon, the temperature in the furnace was raised to 1000 °C, and then hydrogen was introduced for annealing for 40 minutes, and then methane was introduced as a carbon source to grow graphene for 13 minutes. Natural cooling in gas and hydrogen.

[0050] (2) Spin-coat a layer of paraffin wax on the surface of copper foil with graphene growth as a transfer medium.

[0051] (3) Copper foil with FeCl 3 / HCl etching solution to remove, leaving the graphene supported by the paraffin layer, and cleaned with deionized water.

[0052] (4) Deposit a 40nm thick copper film on the PI substrate by vacuum evaporation.

[0053] (5) Transfer the graphene supported by the paraffin layer to the surface of the copper film deposited on the PI substrate, and remove the paraffin layer by thermal evaporation.

[0054] (6) Alternatel...

Embodiment 3

[0056] (1) The 50 μm thick copper foil was cleaned with deionized water, acetone, and ethanol in sequence, and then placed in a tube furnace. Under the protection of argon, the temperature in the furnace was raised to 1000 °C, and then hydrogen was introduced for annealing for 40 minutes, and then methane was introduced as a carbon source to grow graphene for 13 minutes. Natural cooling in gas and hydrogen.

[0057] (2) Spin-coat a layer of PMMA film on the surface of copper foil grown with graphene as a transfer medium.

[0058] (3) Copper foil with CuSO 4 / HCl etching solution is removed, and the graphene supported by the PMMA film remains, and is cleaned with deionized water.

[0059] (4) A 80 nm thick copper film was deposited on the PET substrate by magnetron sputtering.

[0060] (5) The graphene supported by the PMMA film was transferred to the surface of the copper film deposited on the PET substrate, and the PMMA film was removed by cleaning with acetone.

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com