Transition metal composite catalyst for purifying fire coal organic exhaust gas and preparation method and application of transition metal composite catalyst

A composite catalyst and transition metal technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of complex composition and high dust content of coal-fired flue gas , large flue gas volume and other issues, to achieve excellent activity and high COx selectivity, high oxidation performance, wide temperature window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

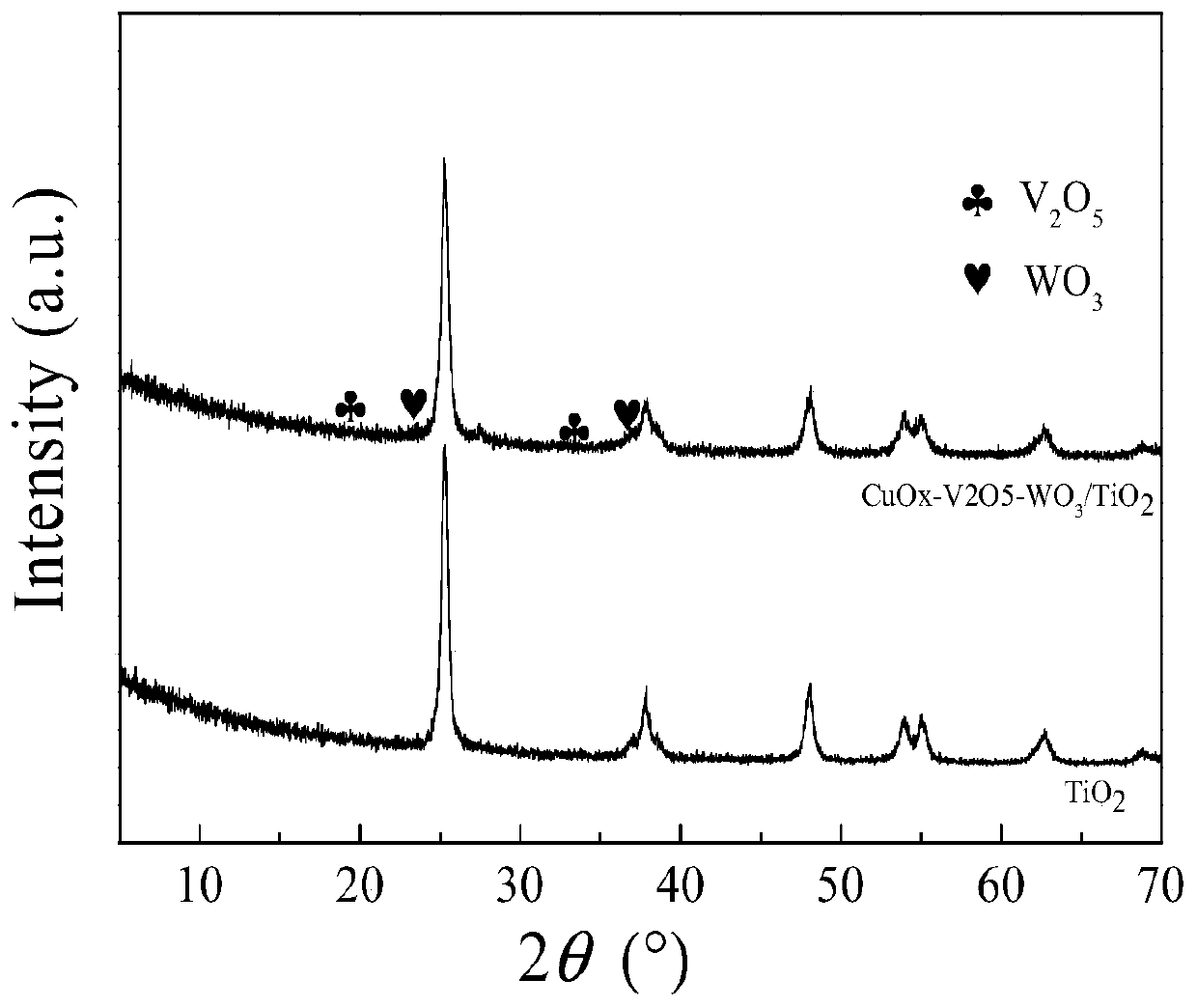

[0038] CuOx-V 2 o 5 -WO 3 / TiO 2 Preparation of:

[0039] (1) Dissolution of V and W precursors:

[0040] Add 0.0458 g of the V precursor ammonium metavanadate and 0.1654 g of the W precursor ammonium tungstate into 20 mL of deionized water and mix thoroughly, then place them in a collector-type constant temperature magnetic stirrer and stir for 30 minutes to dissolve them. Add 0.8 g of oxalic acid precursor under stirring state, continue to stir vigorously at constant temperature after ultrasonication for 60 min, and prepare a mixed precursor solution.

[0041] (2) Dissolution of Cu precursor:

[0042] 0.54 g of copper nitrate was added under stirring, and after ultrasonication, constant temperature and strong stirring was continued for 30 min to prepare a mixed precursor solution.

[0043] (3) TiO 2 pre-processing:

[0044] TiO will be used as catalyst support 2 Take out after drying in a vacuum oven, cool to room temperature for use; the TiO 2 The mass is 2 g.

[0...

Embodiment 2

[0049] CuOx-V 2 o 5 -MoO 3 / TiO 2 Catalyst preparation:

[0050] (1) Dissolution of V and Mo precursors:

[0051] Add 0.0458 g of the V precursor ammonium metavanadate and 0.1654 g of the Mo precursor ammonium molybdate into 20 mL of deionized water and mix them thoroughly, then place them in a collector-type constant temperature magnetic stirrer and stir them for 30 minutes to dissolve them. Add 0.8 g of oxalic acid precursor under stirring state, continue to stir vigorously at constant temperature after ultrasonication for 60 min, and prepare a mixed precursor solution.

[0052] (2) Dissolution of Cu precursor:

[0053] 0.54 g of copper nitrate was added under stirring, and after ultrasonication, constant temperature and strong stirring was continued for 30 min to prepare a mixed precursor solution.

[0054] (3) TiO 2 pre-processing:

[0055] TiO will be used as catalyst support 2 Take out after drying in a vacuum oven, cool to room temperature for use; the TiO 2 T...

Embodiment 3

[0059] CoOx-V 2 o 5 -WO 3 / TiO 2 Preparation of:

[0060] (1) Dissolution of V and W precursors:

[0061] Add 0.0458 g of V precursor ammonium metavanadate and 0.1654 gW precursor ammonium tungstate into 20 mL of deionized water and mix thoroughly, place in a heat-collecting constant temperature magnetic stirrer and stir for 30 minutes to dissolve, then stir Add 0.8g of oxalic acid precursor under the state, continue to stir vigorously at constant temperature after ultrasonication for 60min, and prepare a mixed precursor solution.

[0062] (2) Dissolution of Co precursor:

[0063] Add 0.50 g of cobalt nitrate under stirring state, continue to stir vigorously at constant temperature for 30 min after ultrasonication, and prepare a mixed precursor solution.

[0064] (3) TiO 2 pre-processing:

[0065] TiO will be used as catalyst support 2 Take out after drying in a vacuum oven, cool to room temperature for use; the TiO 2 The mass is 2 g.

[0066] (4) CoOx-V 2 o 5 -WO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap