Engineered strain for producing ethanol and xylitol by efficient utilization of xylitose fermentation

A technology for engineering strains and yeast strains, applied in the directions of fermentation, genetic engineering, microorganism-based methods, etc., can solve the problems of residual substrates, insufficient utilization, and bottlenecks in the purification of product xylitol, so as to improve yield and production. rate, release of glucose inhibitory effect, the effect of great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 constructs heat-resistant yeast strain

[0027] Knockout of xylose reductase gene XR and xylitol dehydrogenase gene XDH in K. marxianu, while overexpressing multiple copies of Neurospora crassa xylose reductase gene NcXR and glucose / xylose symporter gene CiGXF1 , constructed and obtained a heat-resistant yeast strain;

[0028] The specific steps for constructing a heat-resistant yeast strain are described below.

[0029] 1. Extract the yeast genome

[0030] ① Kluyveromyces marxii NBRC177 strain was streaked on a YPD plate, a single clone was picked, inserted into 5ml liquid YPD, cultured at 37°C, 250rpm for 24h.

[0031] ② Centrifuge at 12000rpm at room temperature for 5sec to collect the bacteria, and discard the supernatant.

[0032] ③ Resuspend the bacteria in 500 μl of distilled water, centrifuge at 12,000 rpm for 5 sec to collect the bacteria, and discard the supernatant.

[0033] ④Take 200μl laboratory self-prepared 1x breaking buffer (TritonX-100...

Embodiment 2

[0196] Example 2 Recombinant expression of multiple copies of the N376F mutant gene of Saccharomyces cerevisiae galactose permease in the above-mentioned heat-resistant yeast strain

[0197] 1. Plasmid construction:

[0198] 1) Construction of pQDJL001:

[0199] The genome of Saccharomyces cerevisiae W303 was extracted, and the extracted genome of Saccharomyces cerevisiae was diluted 100 times as a template, with SCGAL2-ECORI-F and SCGAL2-NOTI-R as primers, and PCR was performed using PrimeSTARHS DNA polymerase (Dalian Bao Biology) , the product obtained is ScGAL2, and the ScGAL2 gene and the YEUGAP vector were digested with EcoR I and Not I, and ligated to obtain the plasmid pQDJL001.

[0200] The specific operation is as follows:

[0201] (1) ScGAL2 PCR system:

[0202] 5x PrimeSTAR Polymerase Buffer 40μl 2.5mM dNTP mix 16μl 10 μM SCGAL2-ECORI-F 4μl 10 μM SCGAL2-NOTI-R 4μl Saccharomyces cerevisiae genomic DNA 2μl PrimeSTAR DNA ...

Embodiment 3

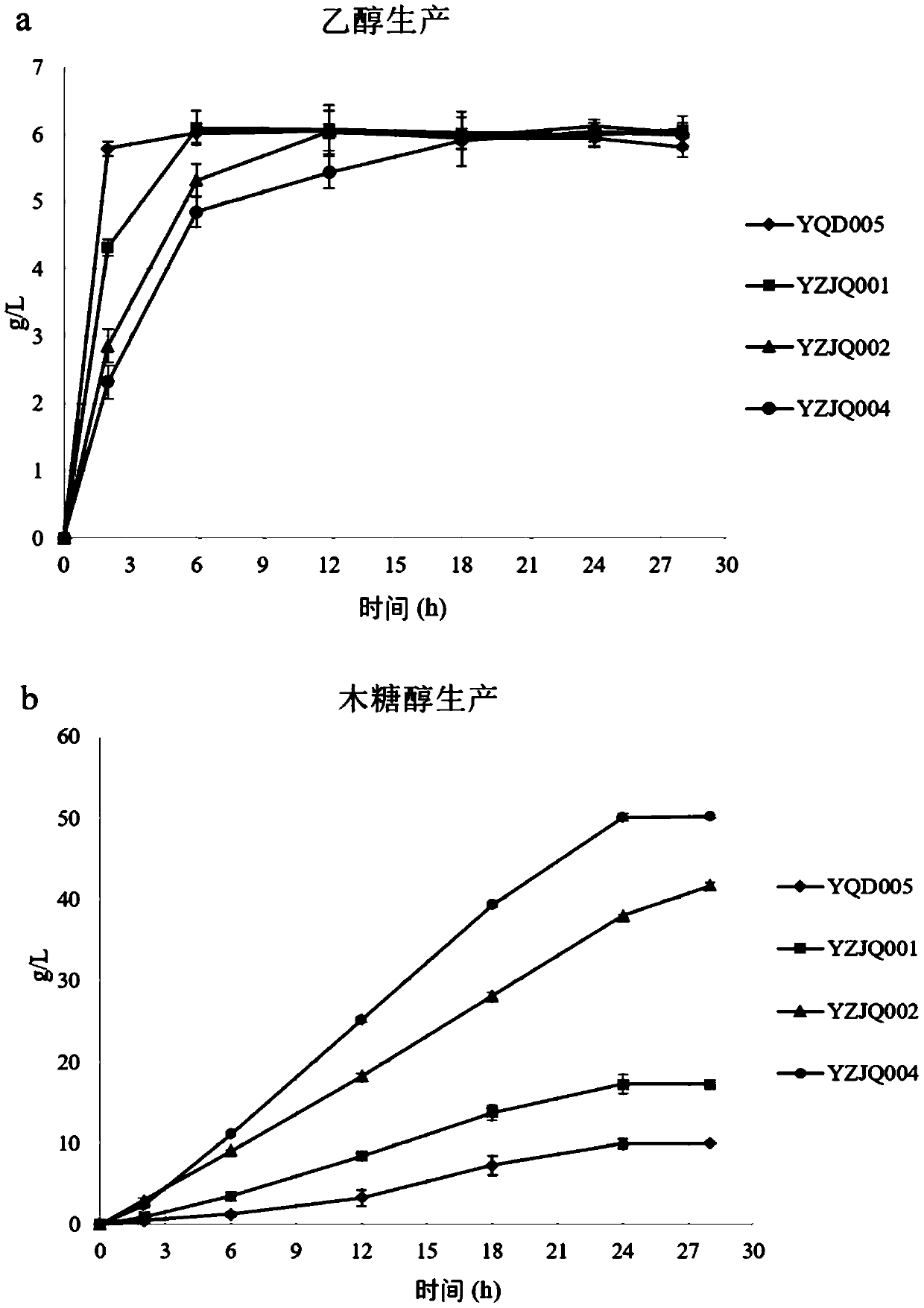

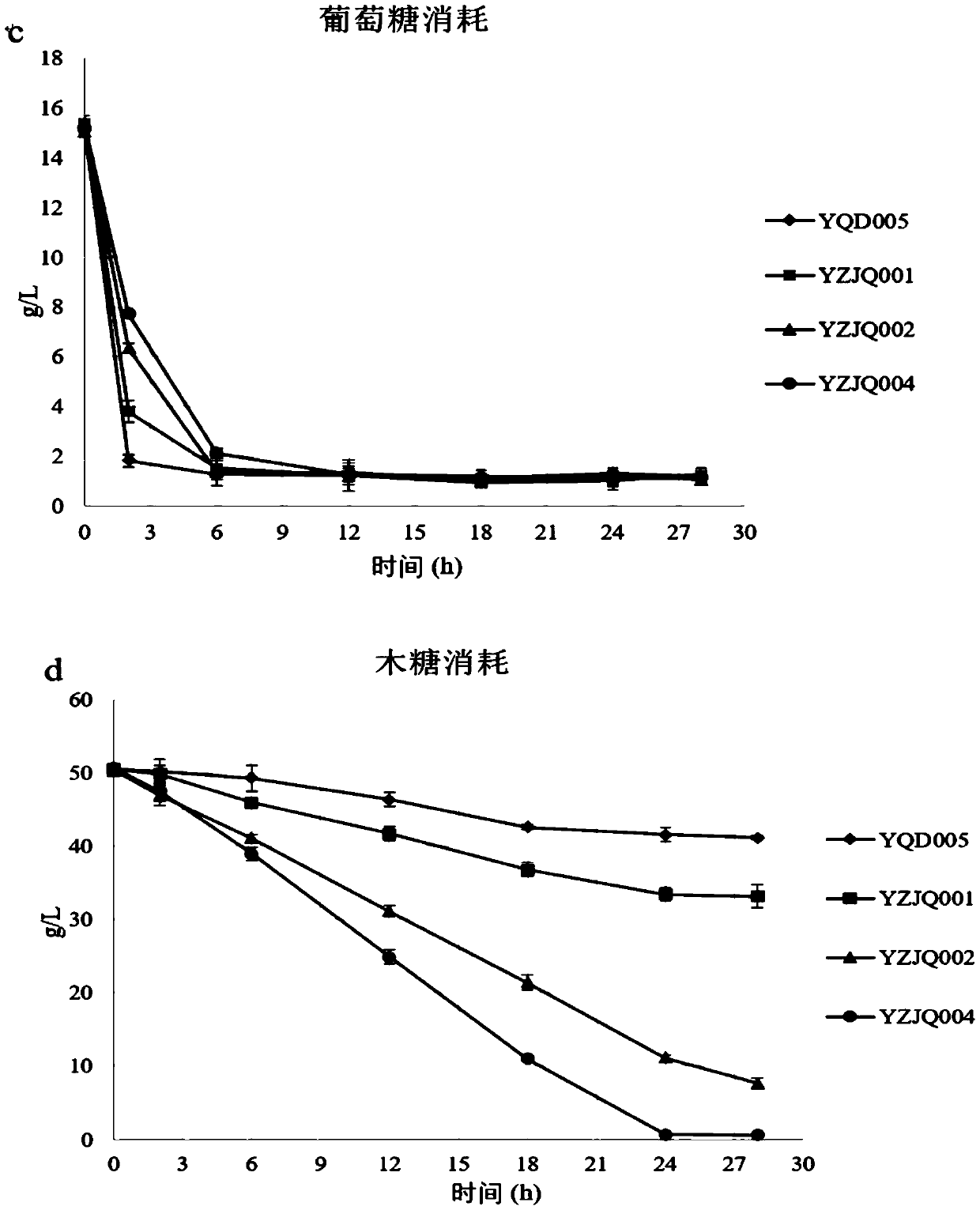

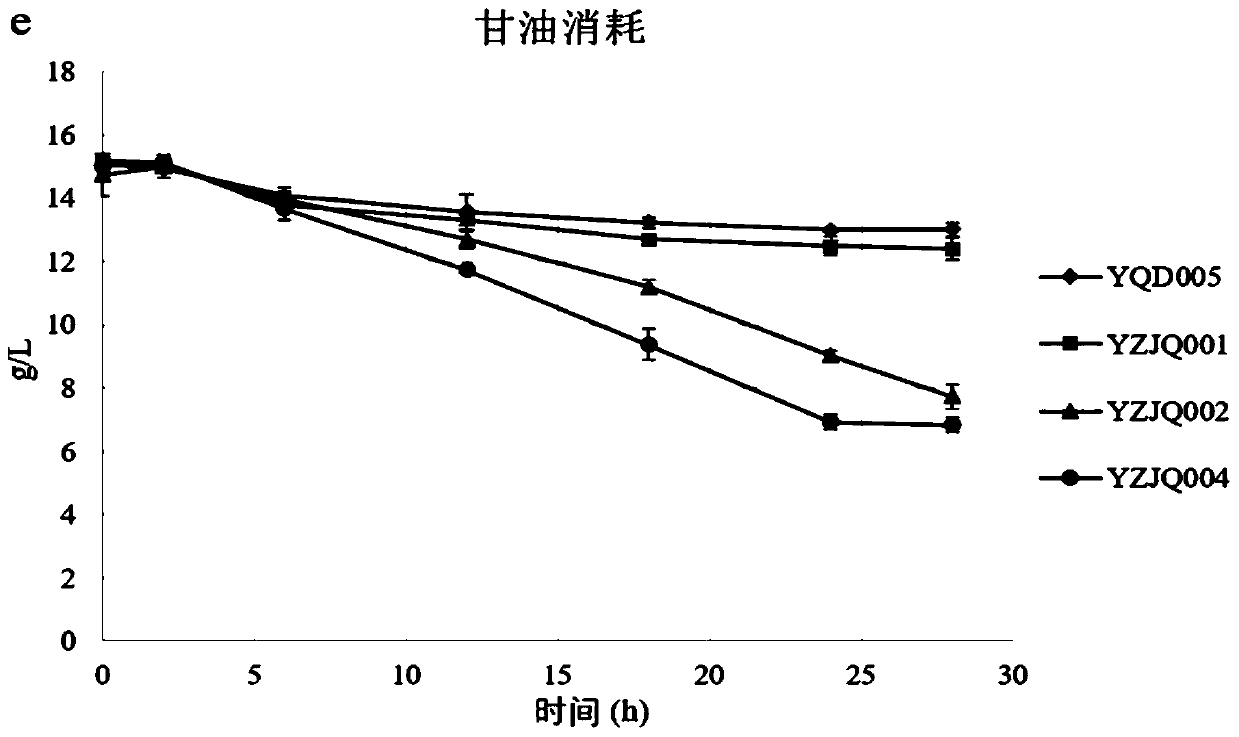

[0313] Co-fermentation effect of the recombinant bacterial strain constructed in embodiment 3 of the present invention

[0314] To compare whether the various process strains constructed can make glucose and xylose fully utilized at the same time by adjusting the addition of glycerol when the ratio of glucose and xylose is consistent. The results showed that in the strain constructed by overexpressing the ScGAL2-N376F gene, xylose could be utilized in the presence of glucose, and the inhibitory effect of glucose was partially released. Moreover, by adding glycerol, all glucose and xylose in the substrate are utilized ( figure 1 ).

[0315]1. Recover strains on YPD medium plates. Control strain: YQD005; experimental strains: YQDJL001, YQDJL002, YQDJL003, YQDJL004. Cultured at 37°C for 1 day.

[0316] 2. Pick out single clones respectively, and connect them to 5ml liquid YPD medium. 37°C, 250rpm, overnight.

[0317] 3. Prepare 12 bottles of 30ml fermentation medium and dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com