Method for improving cycle stability of polymer electrochromic film

A cycle stability, electrochromic technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of easy peeling off of the film, low mechanical strength, cumbersome steps, etc., achieve no pollution in the preparation process, improve cycle stability, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 0.25g of PEDOT:PSS and 50mL of deionized water into a 100mL beaker, and stir at room temperature until completely dissolved. Filter three times, and store the obtained saturated solution in a centrifuge tube for future use. Then the PEDOT:PSS aqueous solution was spin-coated on the ITO surface at a speed of 3000rpm for 30s, and then dried in an oven at 140°C for 10min to obtain an indium tin oxide glass spin-coated with a PEDOT:PSS film.

Embodiment 2

[0029] A method for modifying the electrode surface to improve the stability of electrochromic thin films, using modified indium tin oxide conductive glass after spin-coating PEDOT:PSS spin-coating as a working electrode, a platinum electrode as an auxiliary electrode, and a silver / silver chloride electrode as a reference The specific electrode is polymerized at a constant voltage of 1.2V in a dichloro solution containing 0.75mol / L TBTPA and 0.1mol / L 1-butyl-3-methylimidazolium tetrafluoroborate. At the end, dedope at a negative potential of -0.6V for 60s, rinse the polymer film deposited on the working electrode with dichloromethane; then dry it in a vacuum oven at 60°C for 4 hours to obtain a PTBTPA film, which is smooth and flat The surface morphology (scanning electron microscope as shown in figure 1 shown).

Embodiment 3

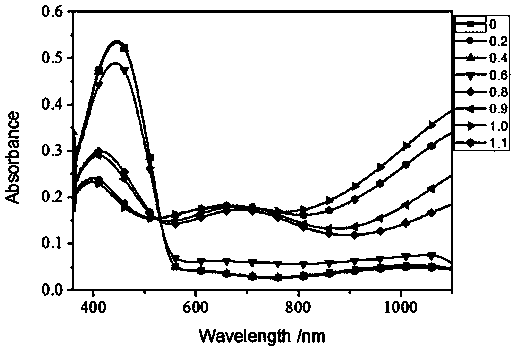

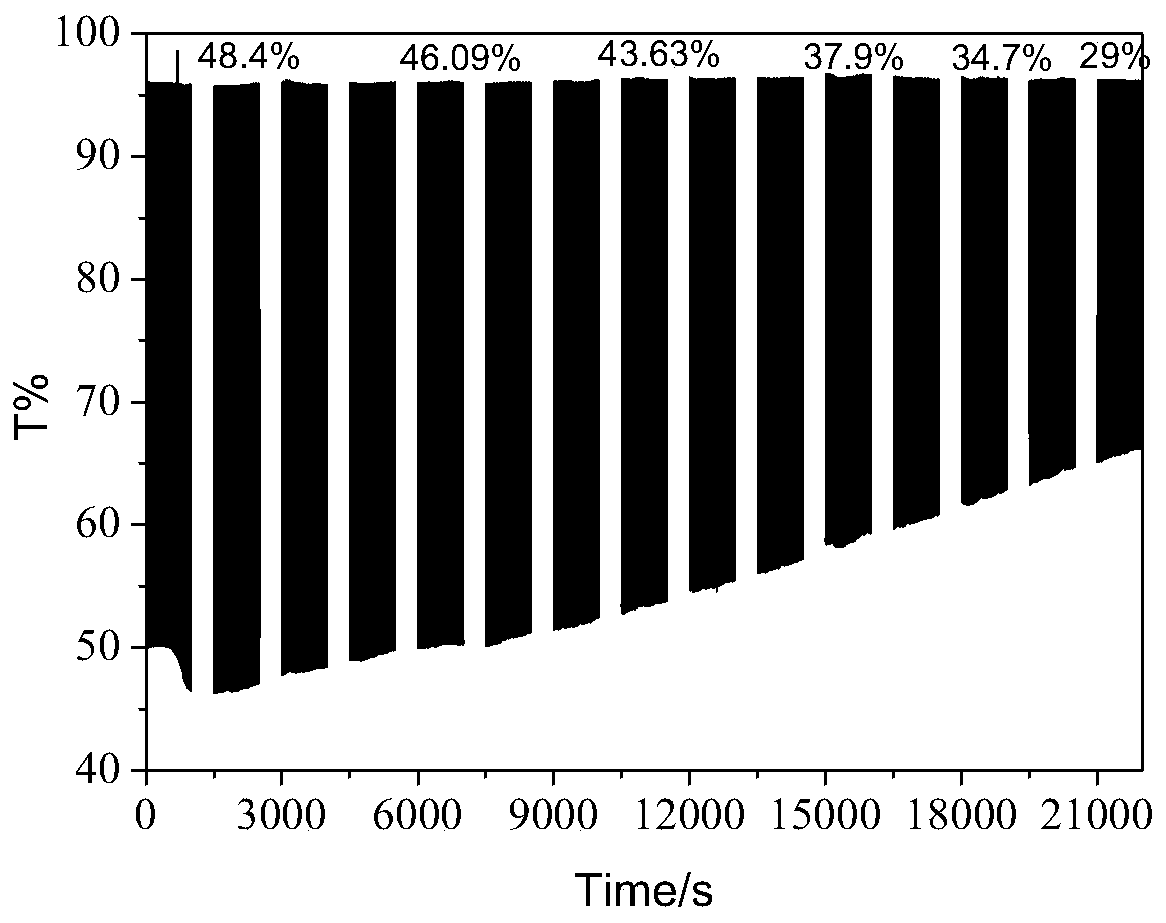

[0031] Morphological characterization, spectroelectrochemical and electrochromic performance tests of the electrochromic thin film, the different applied voltage ranges are 0-1.2V, and different voltages (0V, 0.2V, 0.4V, 0.6V, 0.8V V, 0.9V, 1.0V, 1.1V, 1.2V) UV-visible absorption spectrum (such as figure 2 ), a new absorption peak was generated at 700 nm as the voltage increased, indicating that the film changed from yellow to blue. Using the multi-potential step method, the electrochromic switching response between 0V and 1.1V, the voltage step time is 5s, and the stability test is carried out on the PTBTPA film, and the stability test results of the film are as follows: image 3 shown. Compared to unmodified electrodes (such as Figure 4 ), the PTBTPA film prepared on the electrode modified by PEDOT:PSS showed more excellent cycle stability, that is, after 1000 cycles, the film could maintain an optical contrast of 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com