Preparation method and application of porous graphene-based composite film material

A technology of porous graphene and composite film, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc. Achieve high energy/power density, long cycle life, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

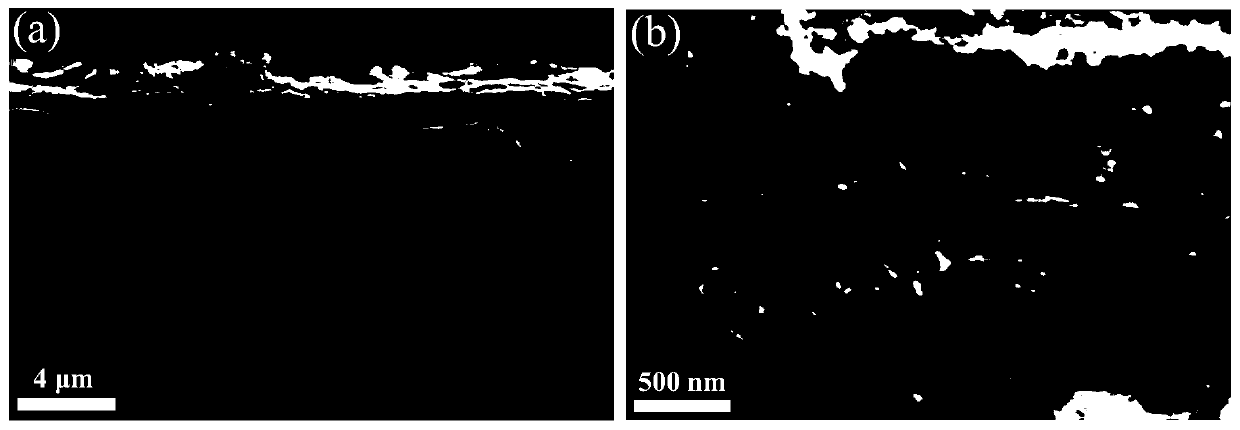

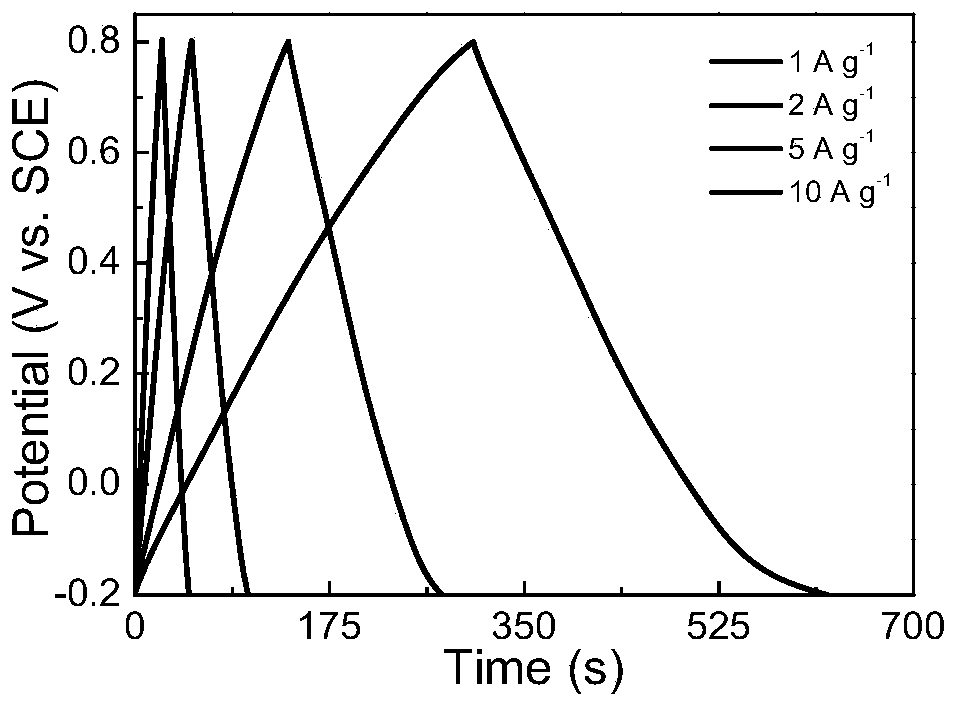

Image

Examples

Embodiment 1

[0047] (1) Preparation of porous graphene dispersion: the graphite oxide dispersion was prepared by the Hummers method, and the concentration of graphite oxide in the aqueous dispersion was 0.5mg mL -1 , take 100mL of graphite oxide dispersion and ultrasonically treat it for 1h to make it evenly dispersed; add 0.0606g of KMnO in the state of continuous stirring 4 , 1000W microwave heating for 5min; when the temperature drops to room temperature, add 50mL deionized water, 100μL hydrazine hydrate and 350μL ammonia water in sequence; after mixing evenly, heat in a water bath at 100°C for 20min, cool to room temperature, add 2g of oxalic acid and stir At least 12h; filter with suction, wash the final product with deionized water to neutrality, and prepare a concentration of 0.33mg mL -1 porous graphene dispersion.

[0048] (2) Carbon nanotubes@MnO 2 Preparation of the dispersion: Take 20mg of carbon nanotubes and disperse them in 200mL of deionized water, add 160mg of KMnO 4 , ...

Embodiment 2

[0056] (1) Preparation of porous graphene dispersion: the graphite oxide dispersion was prepared by the Hummers method, and the concentration of graphite oxide in the aqueous dispersion was 0.2mg mL -1 , take 100mL of graphene oxide suspension and ultrasonically treat it for 1h to make it evenly dispersed; add 0.0545g of KMnO 4 , 800W microwave heating for 10min; when the temperature drops to room temperature, add 50mL deionized water, 200μL hydrazine hydrate and 500μL ammonia water in sequence; after mixing evenly, heat in a water bath at 95°C for 40min, cool to room temperature, add 2g oxalic acid and stir for at least 12h; Suction filtration, the final product was washed with deionized water until neutral, and prepared into 0.2mg mL -1 porous graphene dispersion.

[0057] (2) Carbon nanotubes@Fe 2 o 3 Preparation of dispersion: take 280mg FeCl 3 ·6H 2 O was added to 160mL deionized water, stirred evenly, added 20mg carbon nanotubes, ultrasonically treated to disperse t...

Embodiment 3

[0062] (1) Preparation of porous graphene dispersion: the graphite oxide dispersion was prepared by the Hummers method, and the concentration of graphite oxide in the aqueous dispersion was 1mg mL -1 , take 100mL of graphene oxide suspension and ultrasonically treat it for 1h to make it evenly dispersed; add 0.7271g of KMnO 4 , 1200W microwave heating for 8min; when the temperature drops to room temperature, add 50mL deionized water, 500μL hydrazine hydrate and 700μL ammonia water in sequence; after mixing evenly, heat in a water bath at 98°C for 30min, cool to room temperature, add 2g oxalic acid and stir for at least 12h; Suction filtration, the final product was washed with deionized water until neutral, and prepared into 0.8mg mL -1 porous graphene dispersion.

[0063] (2) Carbon nanotubes@Ni(OH) 2 Preparation of the dispersion: 20 mg of carbon nanotubes were ultrasonically dispersed in 40 mL of deionized water, and 4 mmol of NiCl was added 2 ·6H 2 O, after stirring ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com