Preparation method of high-purity Fe5C2 nanoparticles and application of high-purity Fe5C2 nanoparticles in Fischer-Tropsch synthesis reaction

A nano-particle, high-purity technology, applied in the field of materials, can solve the problems of difficult operation, large amount of waste, restricting industrial production and application, etc., and achieve the effect of stable performance and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 0.1g Fe 3 o 4 Particles (grain size 13nm) are placed in a fixed bed reactor, and a mixed gas of hydrogen and carbon monoxide is introduced, the volume ratio of hydrogen and carbon monoxide is 1:0.5, the flow rate of the mixed gas is 35ml / min, and the temperature is raised at 5°C / min to 400°C; control the temperature of the reaction system and keep it warm for 240 minutes; after the reaction system is cooled, enter an inert atmosphere containing 5% oxygen for passivation treatment for 15 minutes, and collect Fe 5 C 2 Nanoparticle products.

[0042] To the Fe prepared by above-mentioned embodiment 1 5 C 2 Nanoparticles for Characterization:

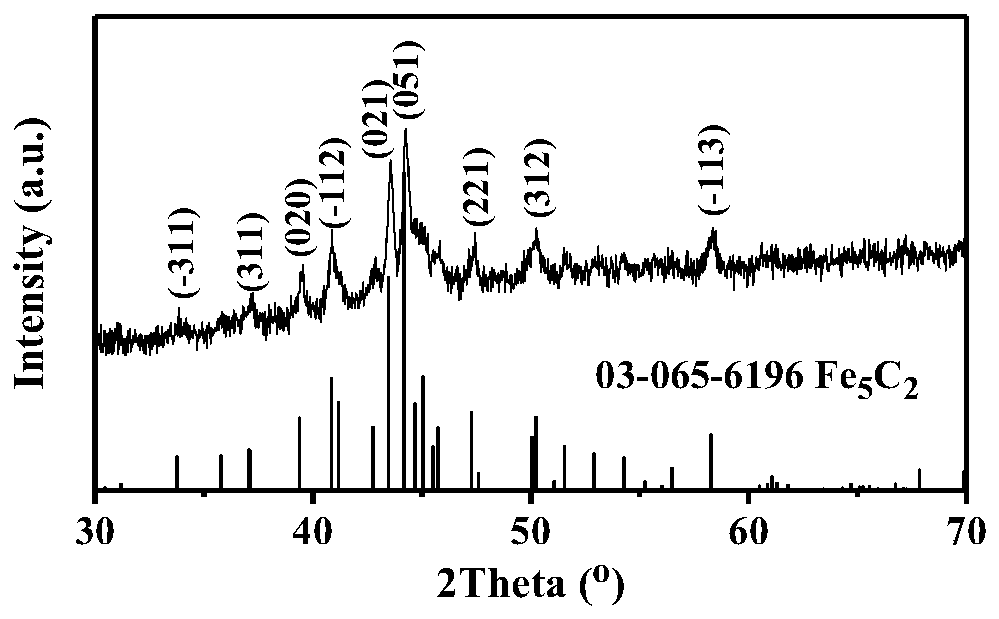

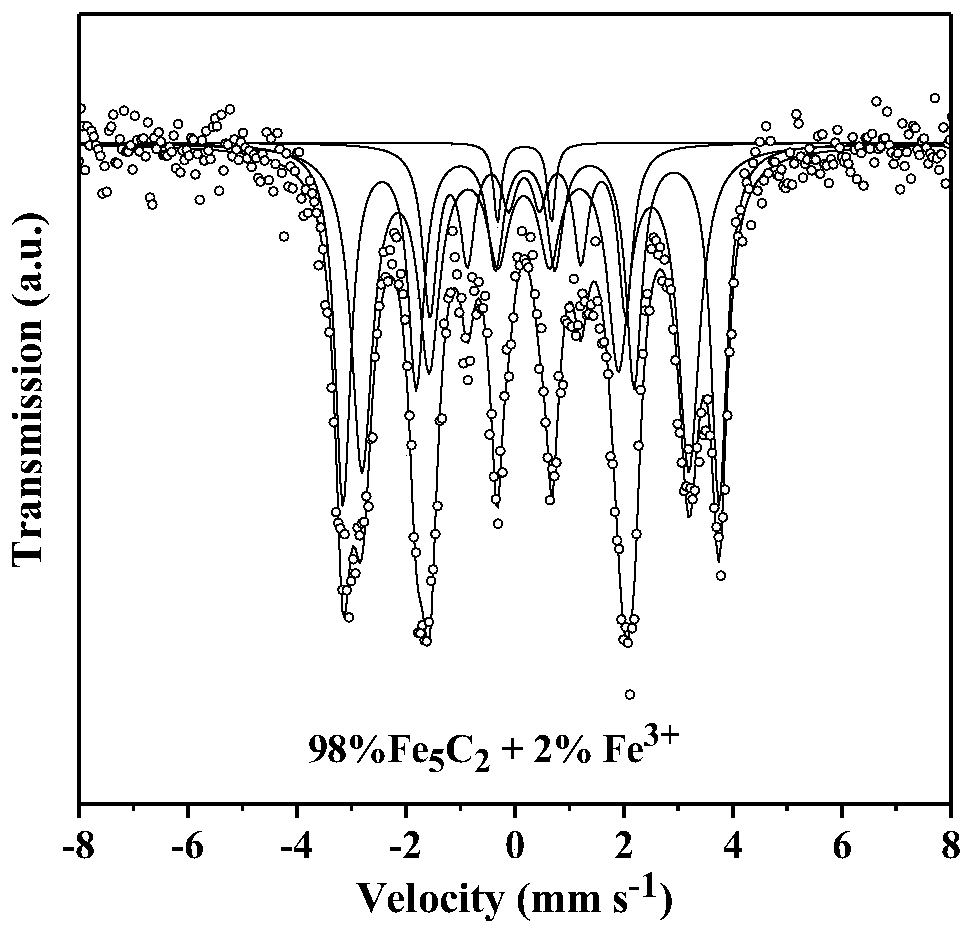

[0043] figure 1 For the Fe prepared in Example 1 5 C 2 Powder X-ray diffraction spectrum of nanoparticles. like figure 1 As shown, the obtained Fe 5 C 2 Diffraction peaks of nanoparticles and Fe 5 C 2 The standard card (ICDD: 03-065-6169) is completely consistent without any miscellaneous peaks, which proves that the ob...

Embodiment 2

[0045] 0.1g Fe 2 o 3 Particles (grain size 38nm) are placed in a fixed bed reactor, and a mixed gas of hydrogen and carbon monoxide is introduced, the volume ratio of hydrogen and carbon monoxide is 1:1, the flow rate of the mixed gas is 20ml / min, and the temperature is raised at 5°C / min to 350°C; control the temperature of the reaction system and keep it warm for 300 minutes; after the reaction system is cooled, pass through an inert atmosphere containing 5% oxygen for passivation treatment for 15 minutes, and collect Fe 5 C 2 Nanoparticle products.

[0046] For this example Fe 5 C 2 Nanoparticles are subjected to powder X-ray diffraction tests such as Figure 4 , this embodiment obtains high-purity Fe 5 C 2 For nanoparticles, the grain size obtained by calculating the half-peak width is 22nm.

Embodiment 3

[0048] Put 0.2g of FeO particles (grain size 28nm) in a fixed bed reactor, pass in a mixture of hydrogen and carbon monoxide, the ratio of hydrogen to carbon is 1:0.5, the flow rate is 50ml / min, and the temperature is raised to 300°C at 2°C / min ; control the temperature of the reaction system and keep it warm for 30 minutes; after the reaction system is cooled, feed into an inert atmosphere containing 5% oxygen to carry out passivation treatment for 15 minutes, and collect Fe 5 C 2 Nanoparticle products.

[0049] For this example Fe 5 C 2 Nanoparticles are tested by powder X-ray diffraction spectroscopy, such as Figure 5 , this embodiment obtains high-purity Fe 5 C 2 Nanoparticles, the grain size obtained by calculating the half peak width is 12nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com