A kind of method adopting emulsion template to control dinitramide ammonium particle size

A technology of ammonium dinitramide and emulsion template, which is applied in the production of compressed gas, explosives, attack equipment, etc., can solve problems such as potential safety hazards, recrystallization of ammonium dinitramide, affecting product appearance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

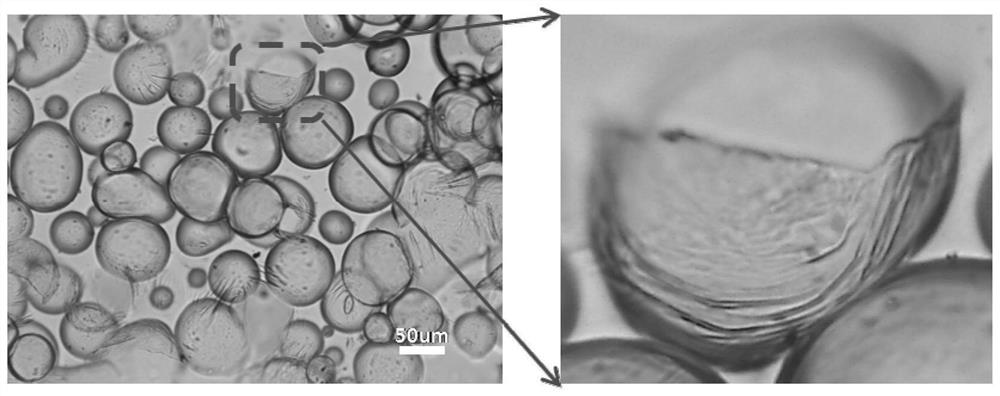

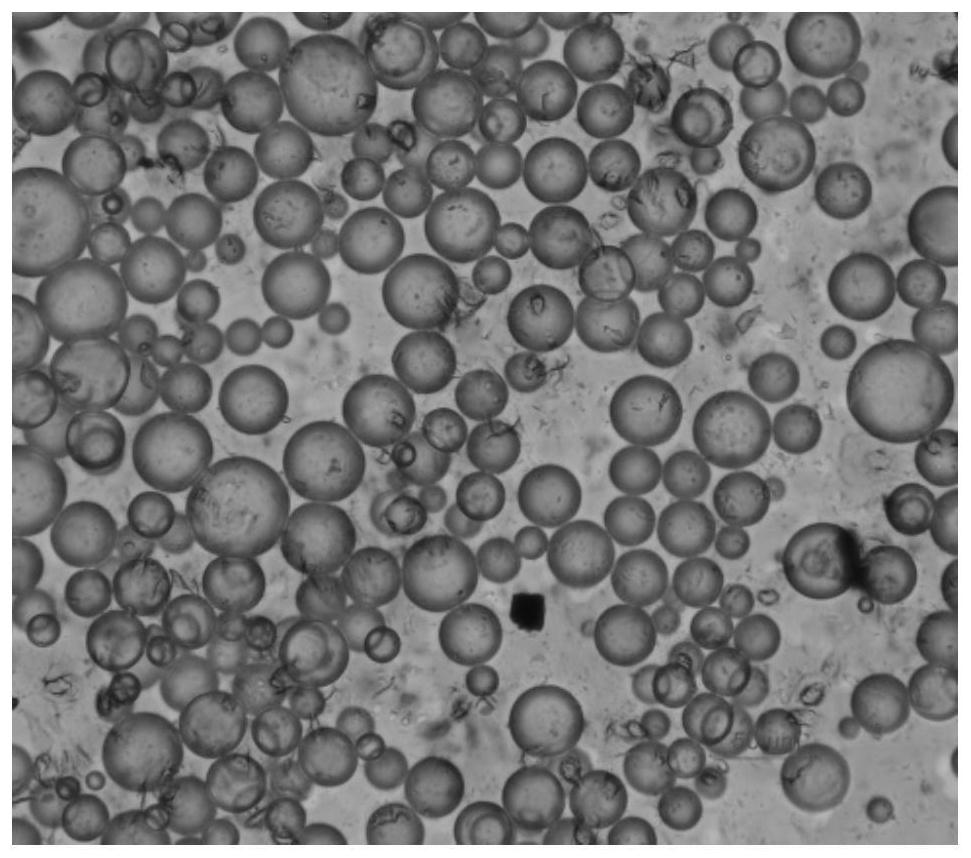

Image

Examples

Embodiment 1

[0028] This embodiment provides a kind of method that adopts emulsion template to control the particle size of dinitramide ammonium, and this method specifically comprises the following steps:

[0029] Step 1, surface modification of template graphene oxide

[0030] Add 0.1g of graphene oxide into 100mL of deionized water; dissolve 1.0g of dodecylamine in 100mL of absolute ethanol by mass; mix the above two parts, stir at 90°C for 24h, and condense the reaction system to reflux, Filtrate, ultrasonically disperse the filtered product in 100 mL of absolute ethanol for 30 minutes, and filter to obtain the precipitated reaction product; repeat the above process 4 times, and vacuum-dry the filtered product at 60°C to obtain alkylamine-modified graphene oxide;

[0031] Step 2, preparation of water-in-oil emulsion

[0032] Ultrasonically disperse 0.005g of alkylamine-modified graphene oxide in 10mL of toluene for 30min, ultrasonic power 1000W, frequency 200Hz, temperature 30°C; add ...

Embodiment 2

[0038] This example provides a method for controlling the particle size of ammonium dinitramide by using an emulsion template. Steps 1, 2, and 3 of this method are the same as those in Example 1, except for Step 4.

[0039] Step 4, the preparation of ammonium dinitramide powder

[0040] Let the emulsion stand at 20°C for 24h, remove the unemulsified toluene solvent in the upper layer of the emulsion, then place the product in a vacuum freeze dryer, and dry it at -50°C, 10Pa vacuum environment for 5h to obtain alkylamine-modified graphene-coated Ammonium dinitramide solid phase composite powder.

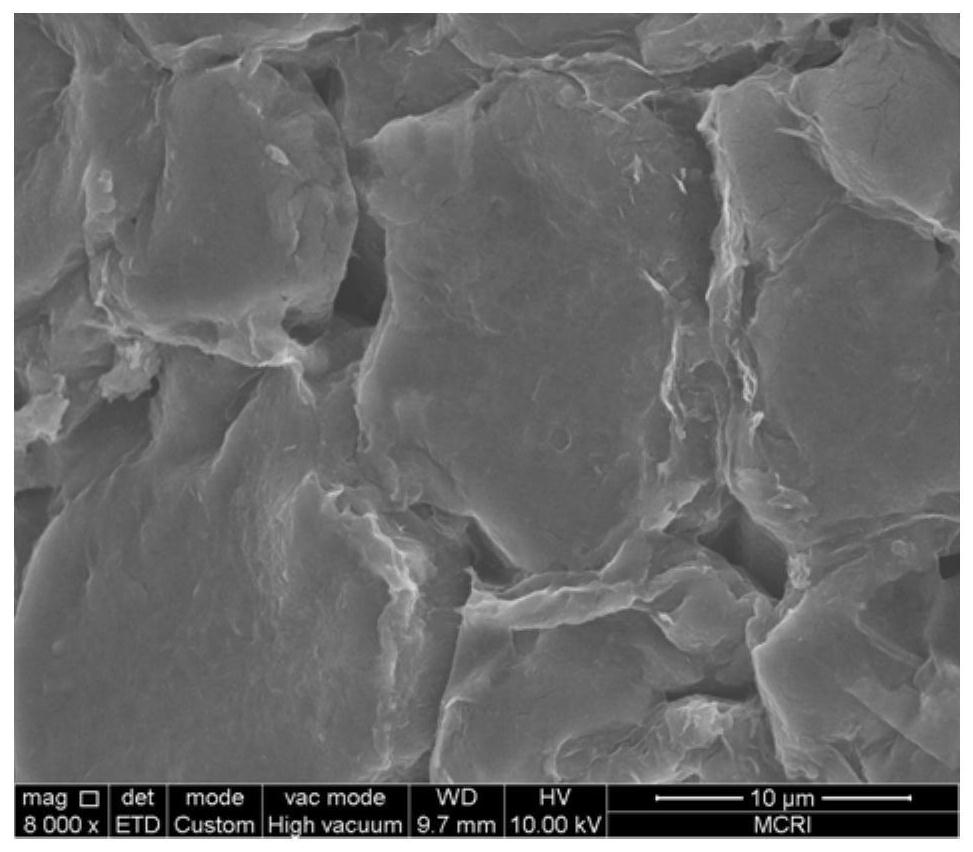

Embodiment 3

[0042] This embodiment provides a kind of method that adopts emulsion template to control the particle size of dinitramide ammonium, and this method specifically comprises the following steps:

[0043] Step 1, template agent silica surface modification

[0044] Add 1.0 g of silicon dioxide to chloroform / oleic acid (molar ratio 1:2), stir for 3 h, and then add methanol to the above mixture to obtain a precipitate of silicon dioxide nanoparticles. The obtained product was dispersed in chloroform, and then methanol was added to precipitate, and the above operation was repeated 4 times to remove excess oleic acid. Then the last precipitated product was dried at 120° C. to obtain oleic acid hydrophobically modified silica.

[0045] Step 2, preparation of water-in-oil emulsion

[0046] Ultrasonically disperse 0.005g of oleic acid-modified silica in 10mL of toluene for 30min, ultrasonic power is 1000W, frequency is 200Hz, temperature is 30°C; The above two dispersions were mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com