Porous composite material long-term sugar control system and preparation method and application thereof

A technology of porous composite materials and porous materials, applied in the field of long-term sugar control system of porous composite materials, to achieve the effects of mild reaction conditions, convenient post-processing, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

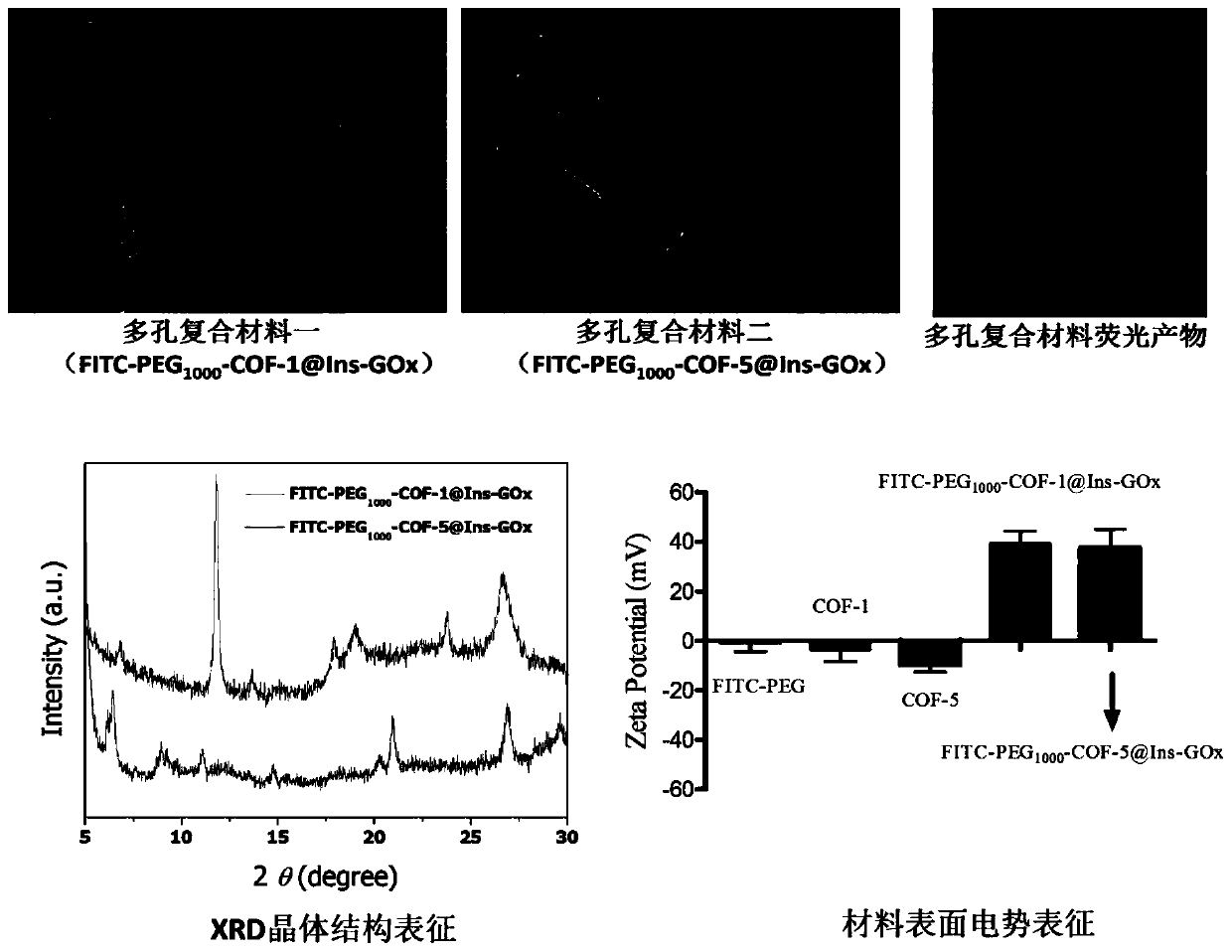

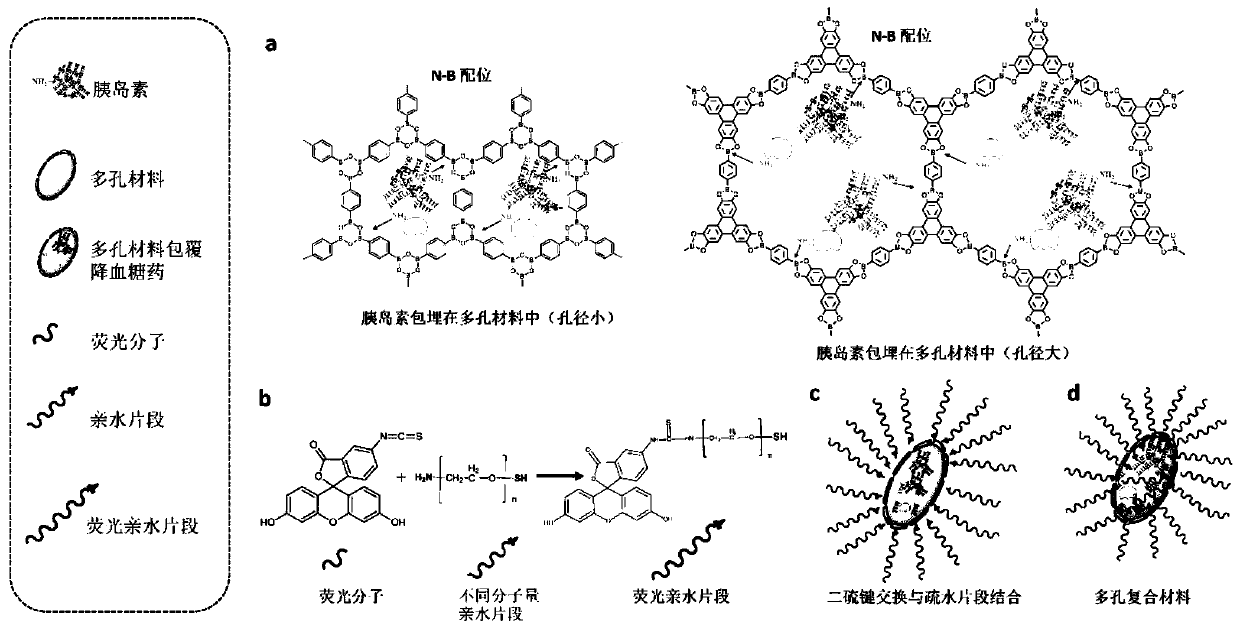

[0031] The preparation method of the porous COFs composite system is as follows:

[0032] (1) Put the sugar-controlling drug insulin (Insulin or Ins for short) and the porous material in a mixed solvent of DMSO and PBS (volume ratio 1:1), and ultrasound to make the sugar-controlling drug fully penetrate into the porous material. In the pores of COF-1 and COF-5; among them, the synthesis of porous materials is a low-temperature (70~130℃) tube-sealing polymerization method, mainly by referring to the first article on COFs synthesis in 2005 (Cote, AP et al. Porous, crystalline, Covalent organicframeworks. Science 2005, 310, 1166-1170).

[0033] (2) Optimizing the product obtained in step (1), using a dialysis method to remove the unembedded sugar-controlling drugs, dialysis and freeze-drying to obtain a porous material loaded drug product;

[0034] (3) Combine the product obtained in step (2) with FITC-modified NH 2 -PEG-SH combined. Specific steps are as follows:

[0035] (a) The 4mg / ...

Embodiment 2

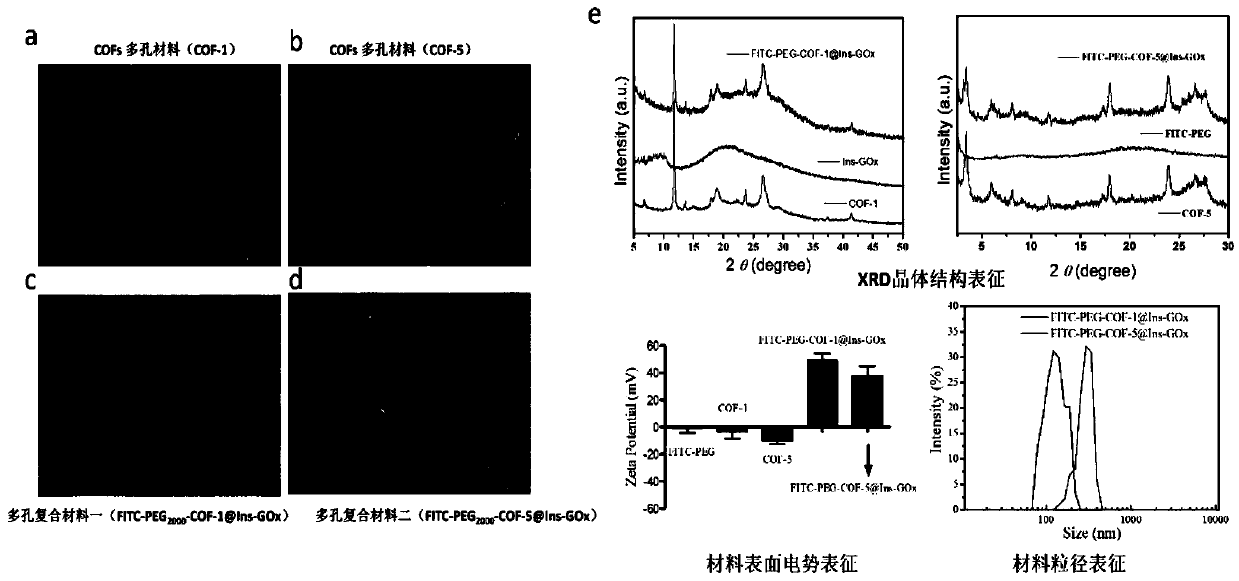

[0041] The preparation method of the porous COFs composite system is as follows:

[0042] (1) Put the sugar control drug insulin (Insulin or Ins for short) and the porous materials COF-1 and COF-5 in a mixed solvent of DMSO and PBS (volume ratio 1:1), and ultrasound to make the sugar control drug Fully penetrate into the pores of porous materials; among them, the synthesis of porous materials adopts low-temperature (70~130℃) sealed tube polymerization method, mainly referring to the first article on COFs synthesis in 2005 (Cote, AP et al. Porous, crystalline, Covalent organicframeworks. Science 2005, 310, 1166-1170).

[0043] (2) Optimize the product obtained in step 1), use a dialysis method to remove unembedded sugar control drugs, and freeze-dry to obtain a porous material loaded product;

[0044] (3) Combine the product obtained in step 2) with FITC-modified NH 2 -PEG-SH (FITC-PEG) combined. Specific steps are as follows:

[0045] (a) The 4mg / mL NH with a molecular weight of 200...

Embodiment 3

[0051] The preparation method of porous COFs composite material long-acting sugar control drug system is as follows:

[0052] (1) Take 2 mg of porous COFs (for example, COF-1, COF-5) materials, and compare them with 4 different 2 mg of glucose control drugs (insulin, biguanide drugs (metformin), sulfonylureas (glibenclamide, Gliclazide, glipizide, gliquidone, glimepiride, etc.), glinide drugs (repaglinide, nateglinide, etc.), alpha glucosidase inhibitors (aka Polose and voglibose, etc.), put them in a 1:1 mixed solvent of DMSO and PBS in a volume ratio of 1:1, and stir for a certain period of time, so that the drugs and COFs can fully permeate and combine with each other, and then shake well overnight. The drug enters the pores of COFs.

[0053] (2) After dialysis, the unbound drug is removed and then lyophilized to obtain a hydrophobic end product (the drug is embedded in a porous material).

[0054] (3) The product obtained in step (2) is combined with FITC modified NH 2 -PEG-SH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com