Preparation method of acrylic resin with branched chain containing polyester chain

A technology of acrylic resin and polyester resin, which is applied in the field of preparation of acrylic resin, can solve the problems of poor drying of polyester resin, low molecular weight of polyester resin, poor drying and other problems, and achieve the effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

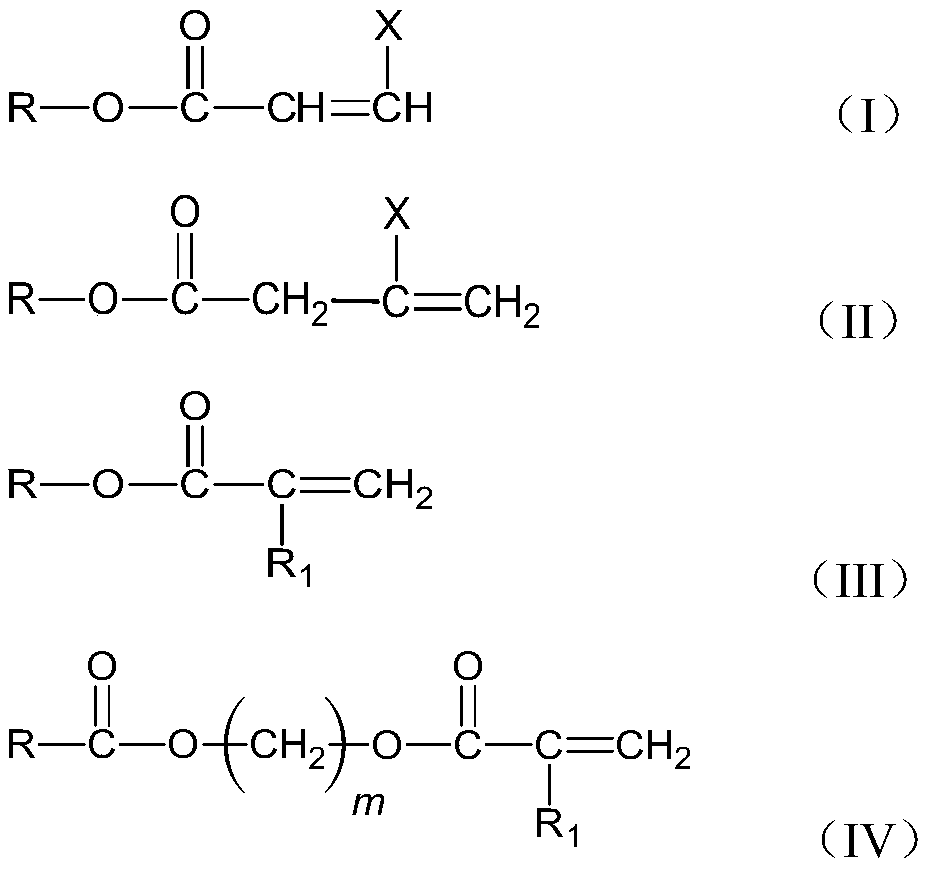

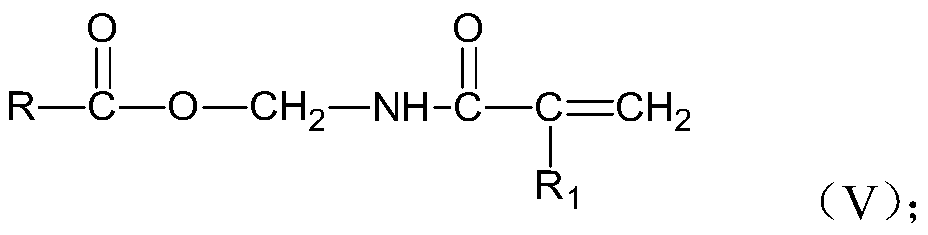

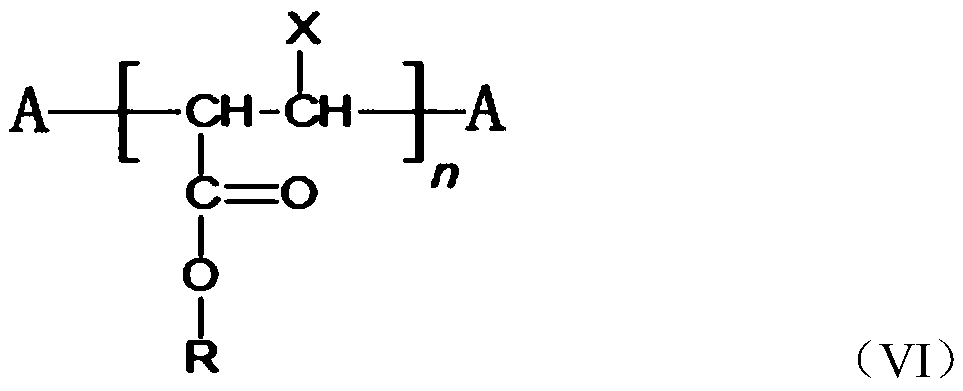

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of polyester intermediate 1

[0042] Add 166.7g of trimethylolpropane (TMP), 269.3g of octapentyl glycol (NPG), 85.5g of 1,6-hexanediol (1,6-HD) and isophthalic acid ( IPA) 448.4g, adipic acid 169g, heat up to 210°C under nitrogen environment, keep warm for esterification reaction, acid value drops below 10mgKOH / g and then cool down, add toluene 328.5g at 120°C, n-butyl acetate 328.5 g and 52g of maleic anhydride, then heat up to 115°C for heat preservation, and the reaction ends when the acid value reaches between 24-28mgKOH / g, the solid content is 60.3%, and the bubble viscosity is O-P, and the acid value of 25mgKOH / g can be obtained Polyester resin with unsaturated double bonds at the end of the molecule.

[0043] (2) Preparation of acrylic resin containing polyester chain on branched chain

[0044]Add 1 250g of polyester intermediate, 24.5g of xylene, and 2g of di-tert-butyl peroxide into the four-necked reaction flask, raise the temperature to 125...

Embodiment 2

[0046] (1) Preparation of polyester intermediate 2

[0047] Same as the synthetic method of intermediate 1 in Example 1, just replace the maleic anhydride therein with oxalic anhydride 64.7g, make solid content be 60.8%, bubble viscosity is Q, the molecule of acid value 23mgKOH / g Polyester resin with unsaturated double bonds at the end.

[0048] (2) Preparation of acrylic resin containing polyester chain on branched chain

[0049] Add 250g of intermediate 2, 24.5g of xylene, and 2g of di-tert-butyl peroxide into the four-necked reaction flask, raise the temperature to 125°C under nitrogen atmosphere, and add 75g of styrene, methyl 80g of methyl acrylate, 75g of tert-butyl acrylate, 50g of butyl methacrylate, 67.5g of 2-hydroxypropyl acrylate, and 2.5g of methacrylic acid are mixed, and 60.5g of n-butyl acetate is added in the initiator dropping tank, Mix 43g of (2-ethylhexanoic acid) tert-butyl peroxide and 5g of tert-butyl peroxybenzoate; after reaching 125°C, the monomer a...

Embodiment 3

[0051] (1) Preparation of polyester intermediate 3

[0052] Add 167.3g of trimethylolpropane (TMP), 270.4g of octapentyl glycol (NPG), 85.9g of 1,6-hexanediol (1,6-HD) and 85.9g of isophthalic acid (IPA) into the four-necked reaction flask. ) 386.5g, adipic acid 209.6g, methacrylic acid 20g, heat up to 210°C under nitrogen environment to carry out esterification reaction, the acid value reaches 15mgKOH / g and lower the temperature, add toluene 328.5g below 120°C, acetic acid is 328.5 g of butyl ester was diluted to obtain a polyester resin having unsaturated double bonds at the molecular end with a solid content of 60.1%, a bubble viscosity of R-S, and an acid value of 8 mgKOH / g.

[0053] (2) Preparation of acrylic resin containing polyester chain on branched chain

[0054] Add 250g of intermediate 3, 24.5g of xylene, and 2g of di-tert-butyl peroxide into the four-necked reaction flask, raise the temperature to 125°C under nitrogen atmosphere, and add 75g of styrene and methac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com