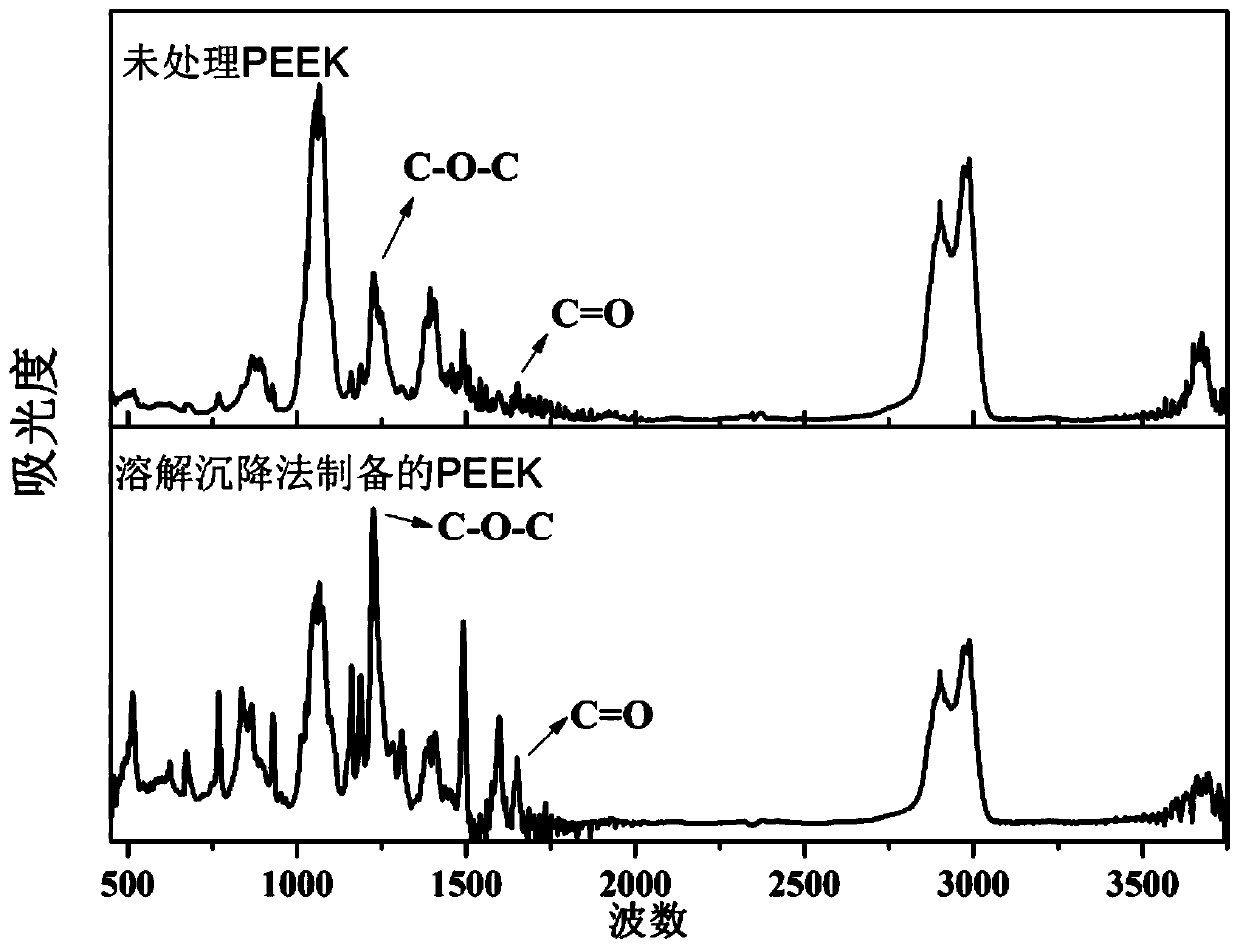

Polyaryletherketone powder and preparation method thereof

A polyaryletherketone and powder technology, which is applied in the field of polyaryletherketone powder and its preparation based on the dissolution and sedimentation method, can solve the problems of heat resistance and mechanical properties decline, unsatisfactory reinforcement effect, and large mechanical energy consumption. Achieve good sphericity and regularity, retain mechanical properties, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An embodiment of the polyaryletherketone powder described in the present invention, the polyaryletherketone powder described in this embodiment is prepared by the following method:

[0033] (1) Add polyarylether ketone raw materials and organic solvents into the reaction vessel, the organic solvent is ethylene glycol, the ratio of the volume of the organic solvent to the weight of the polyarylether ketone raw materials is 3, and feed Nitrogen, exhaust the air in the reaction vessel, heat up while stirring, the stirring rate is 500r / min, the heating rate is 3°C / min, when the temperature is greater than 100°C, keep it warm for 1 hour, and then the solution is heated at a rate of 0.1°C / min Cool down to room temperature, precipitate out, take out the product and let stand;

[0034] (2) washing and drying the precipitate obtained in step (1) to obtain the polyarylether ketone powder; wherein, the washing process is: successively centrifuging and washing with ethanol, acetone...

Embodiment 2

[0036] An embodiment of the polyaryletherketone powder described in the present invention, the polyaryletherketone powder described in this embodiment is prepared by the following method:

[0037] (1) Add polyarylether ketone raw materials and organic solvents into the reaction vessel, the organic solvent is phenol; the ratio of the volume of the organic solvent to the weight of the polyarylether ketone raw materials is 100, and nitrogen gas is passed into it, Exhaust the air in the reaction vessel, heat up while stirring, the stirring rate is 1000r / min, the heating rate is 4°C / min, when the temperature is greater than 100°C, keep it warm for 20 hours, and then lower the solution at a cooling rate of 5°C / min To room temperature, precipitation precipitated, and the product was taken out and allowed to stand;

[0038] (2) washing and drying the precipitate obtained in step (1) to obtain the polyarylether ketone powder; wherein, the washing process is: successively centrifuging a...

Embodiment 3

[0040] An embodiment of the polyaryletherketone powder described in the present invention, the polyaryletherketone powder described in this embodiment is prepared by the following method:

[0041] (1) Add polyarylether ketone raw materials and organic solvents into the reaction vessel, the organic solvent is dimethyl sulfoxide, the ratio of the volume of the organic solvent to the weight of the polyarylether ketone raw materials is 40, usually Inject nitrogen, discharge the air in the reaction vessel, heat up while stirring, the stirring rate is 700r / min, the heating rate is 3.5°C / min, keep warm for 2 hours after the temperature is greater than 100°C, and then the solution is heated at a rate of 1°C / min The cooling rate is lowered to room temperature, a precipitate is precipitated, and the product is taken out and left standing;

[0042] (2) washing and drying the precipitate obtained in step (1) to obtain the polyaryletherketone powder; wherein, the washing process is: sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com