In-situ doped nanometer calcium carbonate chitin hydrogel, and preparation method and application thereof

A nano-calcium carbonate and in-situ doping technology, which is applied in the field of material chemistry, can solve the problems of strong alkali equipment corrosion, high price, and application limitations, and achieve the effects of enhanced adsorption performance, fast desorption speed, and good dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

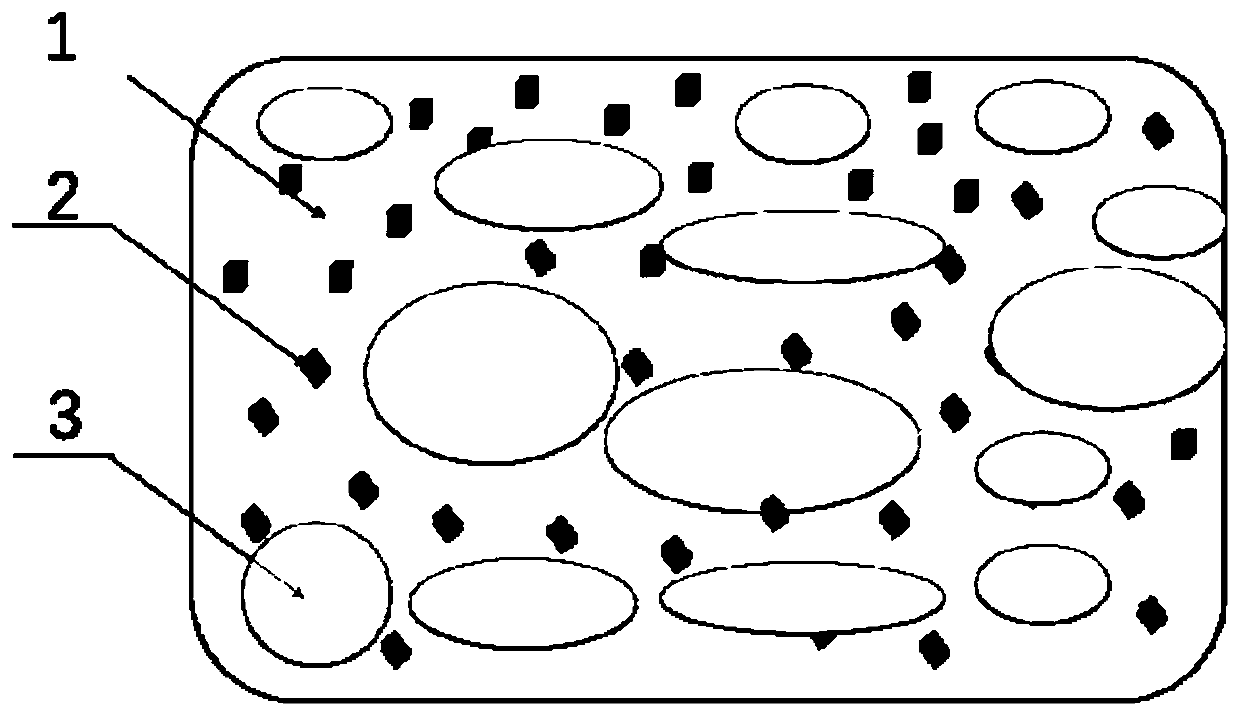

Image

Examples

Embodiment 1

[0048] A preparation method of in-situ doped nano calcium carbonate chitin hydrogel, comprising the following steps:

[0049] (1) dissolving chitin: first according to 15wt%Na 2 CO 3 / 10wt%Ca(OH) 2 Prepare the solution at a ratio of 4 wt% urea to obtain 100ml of solvent, then add 2g of chitin to the solvent, stir evenly, then freeze at -40°C for 12h, then thaw, repeat 3 times to obtain a viscous mixture;

[0050] (2) Preparation of preliminary hydrogel: Stir the viscous mixture evenly, then filter to obtain the filtrate, add 7g of epichlorohydrin to the filtrate for cross-linking reaction, the reaction temperature is 0°C, and the reaction time is 1.5h, and then the The obtained solution was introduced into the mold, and placed at room temperature for 4 hours to obtain a preliminary hydrogel;

[0051] (3) Preparation of hydrogel: Soak the preliminary hydrogel at -4°C for 10 h in a mixture of ethanol / water with a volume ratio of 1:1, and then wash until neutral to obtain a hy...

Embodiment 2

[0055] A preparation method of in-situ doped nano calcium carbonate chitin hydrogel, comprising the following steps:

[0056] (1) dissolving chitin: first according to 30wt%Na 2 CO 3 / 20wt%Ca(OH) 2 Prepare the solution at a ratio of 6 wt% urea to obtain 100ml of solvent, then add 3g of chitin to the solvent, stir evenly, then freeze at -39°C for 12 hours, then thaw, repeat 4 times to obtain a viscous mixture;

[0057] (2) Preparation of preliminary hydrogel: Stir the viscous mixture evenly, then filter to obtain the filtrate, add 7.5g epichlorohydrin to the filtrate to carry out cross-linking reaction, the reaction temperature is 2°C, the reaction time is 2h, and then the The obtained solution was introduced into the mold, and placed at room temperature for 5 hours to obtain a preliminary hydrogel;

[0058] (3) Preparation of hydrogel: Soak the preliminary hydrogel at -2°C for 12 hours in a mixture of ethanol / water with a volume ratio of 3:1, and then wash until neutral to ...

Embodiment 3

[0062] A preparation method of in-situ doped nano calcium carbonate chitin hydrogel, comprising the following steps:

[0063] (1) dissolving chitin: first according to 20wt%Na 2 CO 3 / 15wt%Ca(OH) 2 Prepare the solution at a ratio of 3 wt% urea to obtain 100ml of solvent, then add 1g of chitin to the solvent, stir evenly, then freeze at -38°C for 12h, then thaw, repeat twice to obtain a viscous mixture;

[0064] (2) Preparation of preliminary hydrogel: Stir the viscous mixed solution evenly, then filter to obtain the filtrate, add 4g epichlorohydrin to the filtrate to carry out cross-linking reaction, the reaction temperature is 4°C, the reaction time is 1h, and then the obtained The solution was introduced into the mold and placed at room temperature for 3 hours to obtain a preliminary hydrogel;

[0065] (3) Preparation of hydrogel: Soak the preliminary hydrogel at 0° C. for 15 hours with a mixture of ethanol / water with a volume ratio of 5:1, and then wash until neutral to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com