Halogen-free high flame retardant polymer material for reinforcing coal and rock mass in coal mines and preparation method thereof

A polymer material and high flame-retardant technology, applied in mining equipment, earthwork drilling, wellbore/well parts, etc., can solve the problems of flame-retardant performance degradation, environmental pollution, etc., and achieve moderate viscosity, good hydrolytic stability, The effect of suppressing the generation of combustible gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

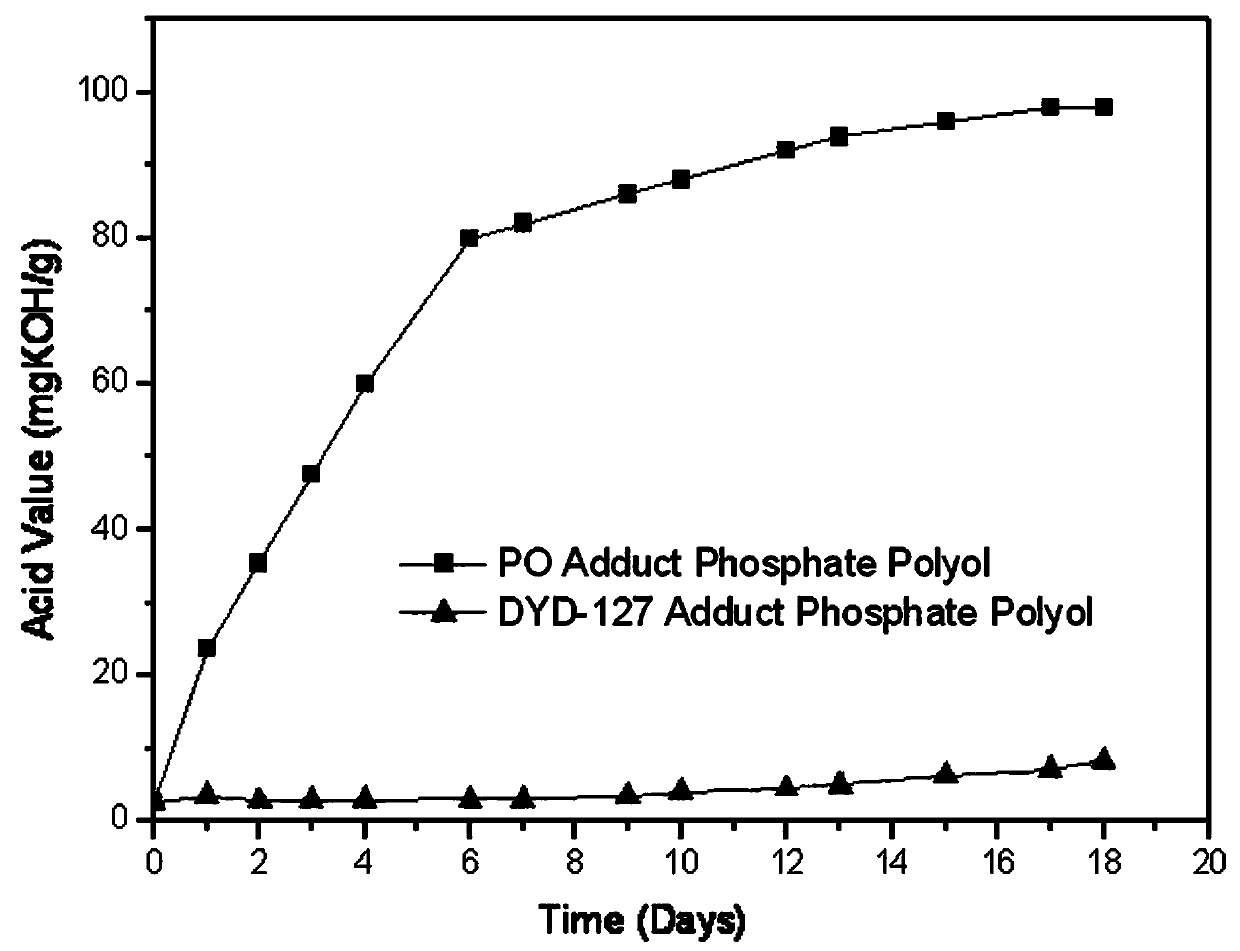

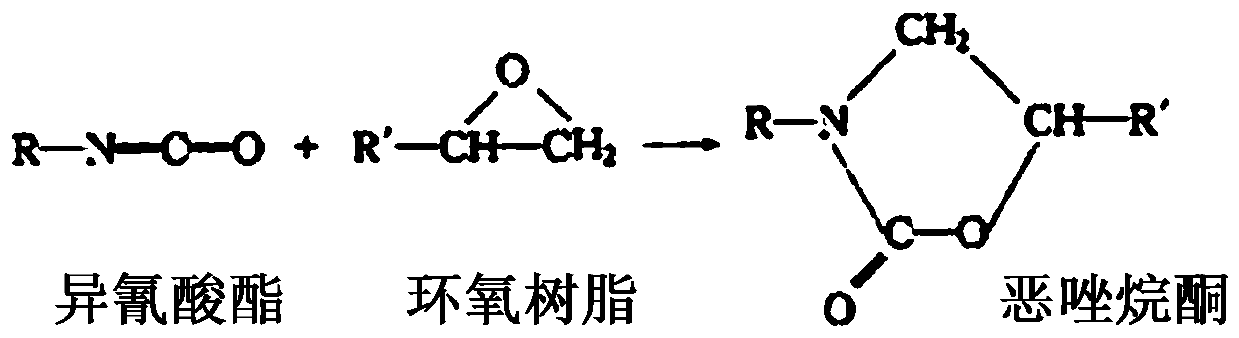

[0031] Example 1: The preparation method of epoxy phosphate polyol is: place 100g triethyl phosphate, 0.2g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 2L four-neck bottle, and ensure the nitrogen environment in the four-neck bottle, then slowly raise the temperature to 80°C, add 50g of phosphorus pentoxide, keep the temperature at 85°C for 5 hours, and start adding 100g of trimethylol dropwise after obtaining a transparent solution Phosphine oxide, keep reflux and condense, continue to react for 3 hours, add 100g of epoxy resin DYD-127, 0.05g of stannous octoate, control the temperature at 85 ℃, and feed 15g of ethylene oxide until the acid value is less than 2mgKOH / g. Add 25g of epoxy resin DYD-127. After adsorption, filtration, distillation and other processes, the epoxy phosphate polyol with a phosphorus content of 15.63% was obtained, and no hydrolysis phenomenon was found during the storage period.

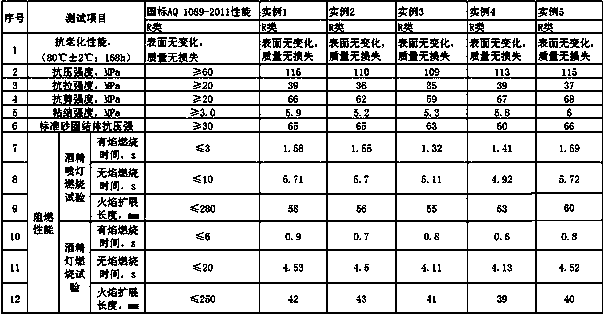

[0032] A halogen-free high-flame-retard...

Embodiment 2

[0033] Embodiment 2: The preparation method of epoxy phosphate ester polyol is: put 130g triethyl phosphate, 0.2g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 2L four-neck bottle, and ensure the nitrogen environment in the four-neck bottle, then slowly raise the temperature to 80°C, add 55g of phosphorus pentoxide, keep the temperature at 85°C for 5 hours, and start adding 120g of trimethylol dropwise after obtaining a transparent solution Phosphine oxide, keep reflux and condense, continue to react for 3 hours, add 180g of epoxy resin DYD-127, 0.05g of stannous octoate, control the temperature at 85 ℃, and feed 20g of ethylene oxide until the acid value is less than 2mgKOH / g. Add 30g of epoxy resin DYD-127. After adsorption, filtration, distillation and other processes, the epoxy phosphate polyol with a phosphorus content of 13.58% was obtained, and no hydrolysis phenomenon was found during the storage period.

[0034] A halogen-free high-flame...

Embodiment 3

[0035] Example 3: The preparation method of epoxy phosphate polyol is: place 150g triethyl phosphate, 0.2g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 2L four-neck bottle, and ensure the nitrogen environment in the four-neck bottle, then slowly raise the temperature to 80°C, add 80g of phosphorus pentoxide, keep the temperature at 85°C for 5 hours, and start adding 150g of trimethylol dropwise after obtaining a transparent solution Phosphine oxide, keep reflux and condense, continue to react for 3 hours, add 110g of epoxy resin DYD-127, 0.05g of stannous octoate, control the temperature at 85 ℃, and feed 25g of ethylene oxide until the acid value is less than 2mgKOH / g. Add 25g of epoxy resin DYD-127. After adsorption, filtration, distillation and other processes, the epoxy phosphate polyol with a phosphorus content of 17.31% was obtained, and no hydrolysis phenomenon was found during the storage period.

[0036] A halogen-free high-flame-retard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com