High-manganese austenitic low-temperature steel electrode with seamless welding core and preparation method

A technology of austenitic and low-temperature steel, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of poor welding processability, low utilization rate of electrodes, easy redness of electrodes, etc., and achieve stable arc, clear molten pool, The effect of good welding processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

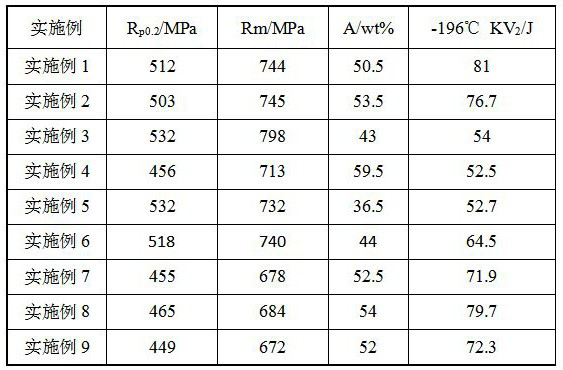

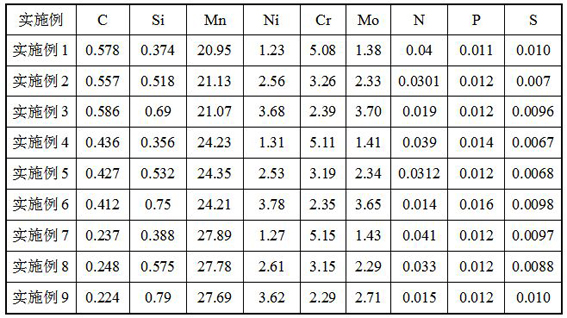

Examples

preparation example Construction

[0024] A preparation method for an electric welding electrode for high manganese austenitic low-temperature steel with a seamless welding core, comprising the following steps:

[0025] (1) Weigh each component in the drug core as required, first bake potassium carbonate and potassium titanate at a high temperature of 440~460°C and keep it warm for 0.8~1.2h to remove water;

[0026] (2) Mix the treated potassium carbonate and potassium titanate with other components in the drug core, and keep warm at 110~130°C after mixing to avoid moisture absorption of potassium carbonate and potassium titanate again, and obtain the drug core pink;

[0027] (3) Weigh each component in the drug skin according to the requirements, and mix and stir evenly to obtain a dry powder, then add pure sodium water glass with a total dry powder weight of 24 to 30% to the dry powder, mix and stir, and the pure sodium water glass The modulus is 3.2 and the density is 1.40~1.45g / mm 3 , Baume degree is 43°;...

Embodiment 1

[0055] An electric electrode for high manganese austenitic low-temperature steel with a seamless welding core, including a welding core and a coating, the welding core includes a flux core and a skin, and the flux core accounts for 34 to 35% of the total weight of the welding core , each component in the described medicine core comprises by weight ratio: metal manganese powder 90%, graphite 3%, potassium carbonate 3%, potassium titanate 0%, reduced iron powder 4%; In described metal manganese powder, comprise following The chemical composition of the mass fraction: Mn≥97.0%, C≤0.05%, S≤0.02%, P≤0.03%, the graphite includes the following chemical composition of the mass fraction: C≥95%, S≤0.10%, P≤ 0.010%, the chemical composition that comprises following mass fraction in described potassium carbonate: K 2 CO 3 ≥98.0%, S≤0.02%, P≤0.02%, the potassium titanate contains the following chemical components in mass fraction: 30~35% Na 2 O+K 2 O, 50~59 TiO 2 , S≤0.02%, P≤0.02%;

...

Embodiment 2

[0065] An electric electrode for high manganese austenitic low-temperature steel with a seamless welding core, including a welding core and a coating, the welding core includes a flux core and a skin, and the flux core accounts for 34 to 35% of the total weight of the welding core , each component in the described medicine core comprises by weight ratio: metal manganese powder 90%, graphite 3%, potassium carbonate 3%, potassium titanate 0%, reduced iron powder 4%; In described metal manganese powder, comprise following The chemical composition of the mass fraction: Mn≥97.0%, C≤0.05%, S≤0.02%, P≤0.03%, the graphite includes the following chemical composition of the mass fraction: C≥95%, S≤0.10%, P≤ 0.010%, the chemical composition that comprises following mass fraction in described potassium carbonate: K 2 CO 3 ≥98.0%, S≤0.02%, P≤0.02%, the potassium titanate contains the following chemical components in mass fraction: 30~35% Na 2 O+K 2 O, 50~59 TiO 2 , S≤0.02%, P≤0.02%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com