Application of hydrotalcite-based catalyst in conversion of high-concentration sugar into 1,2-propylene glycol

A hydrotalcite-based, catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, preparation of hydroxyl compounds, etc., can solve the problems of constraints, poor product selectivity, multi-step reaction, etc. Achieve the effects of high conversion efficiency, high added value of products, and simple and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

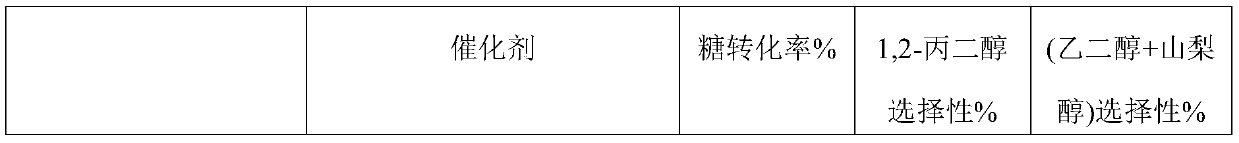

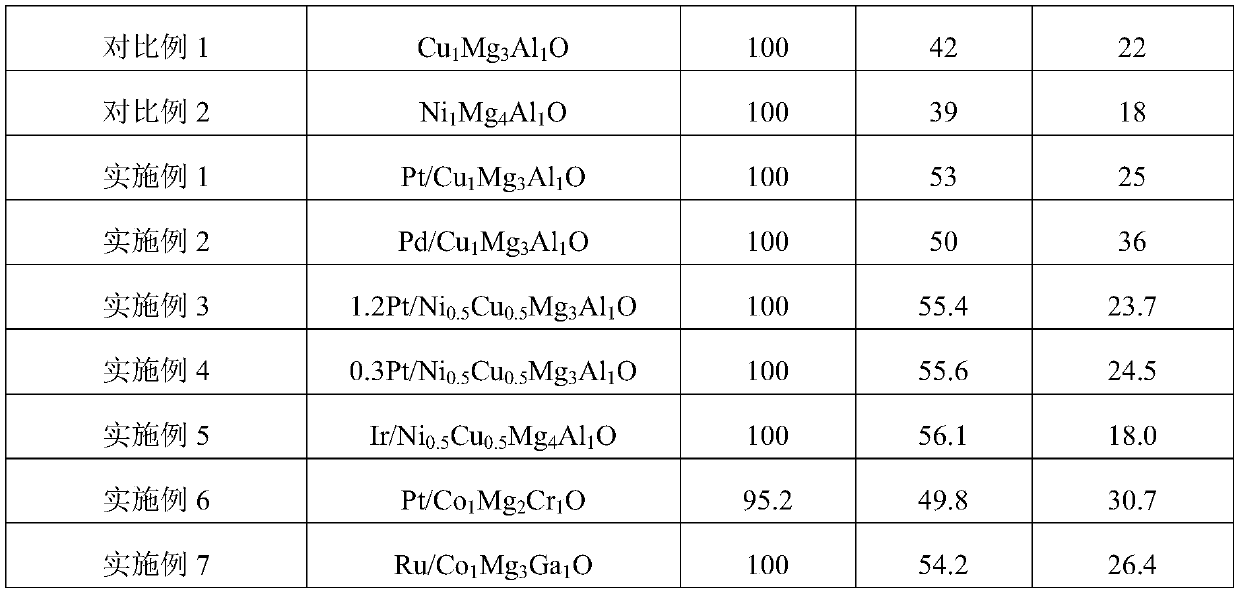

Examples

Embodiment 1

[0041] Pt / Cu 1 Mg 3 Al 1 O catalyst preparation:

[0042] Weigh 0.01 mol of copper nitrate, 0.03 mol of magnesium nitrate and 0.01 mol of aluminum nitrate, dissolve them in deionized water to form mixed salt solution A. In addition, equimolar sodium carbonate and sodium hydroxide were dissolved in deionized water (the molar ratio of sodium carbonate and sodium hydroxide was 4:3; the solution was neutral after the theoretical reaction), and mixed alkali solution B was prepared. Add A dropwise to B in a constant temperature water bath at 40°C, and use a constant flow pump to control the drop rate to 3mL min -1 , stirring vigorously during the dropwise addition. After the dropwise addition, the pH of the above suspension was adjusted to 10 with 3M NaOH solution, and the stirring and crystallization was continued in a constant temperature water bath at 70° C. for 18 hours to obtain a precipitate. After the steps of suction filtration, washing and drying, a hydrotalcite precur...

Embodiment 2

[0045] Pd / Cu 1 Mg 3 Al 1 O catalyst preparation:

[0046] Weigh 0.01 mol of copper nitrate, 0.03 mol of magnesium nitrate and 0.01 mol of aluminum nitrate, dissolve them in deionized water to form mixed salt solution A. In addition, equimolar sodium carbonate and sodium hydroxide were dissolved in deionized water (the molar ratio of sodium carbonate and sodium hydroxide was 4:3; the solution was neutral after the theoretical reaction), and mixed alkali solution B was prepared. Add A dropwise to B in a constant temperature water bath at 40°C, and use a constant flow pump to control the drop rate to 3mL min -1 , stirring vigorously during the dropwise addition. After the dropwise addition, the pH of the above suspension was adjusted to 10 with 3M NaOH solution, and the stirring and crystallization was continued in a constant temperature water bath at 70° C. for 18 hours to obtain a precipitate. After the steps of suction filtration, washing and drying, a hydrotalcite precur...

Embodiment 3

[0049] Pt / Ni 0.5 Cu 0.5 Mg 3 Al 1 O catalyst preparation:

[0050] Weigh 0.005 mol of copper nitrate, 0.005 mol of nickel nitrate, 0.03 mol of magnesium nitrate and 0.01 mol of aluminum nitrate, dissolve them in deionized water to form mixed salt solution A. In addition, equimolar sodium carbonate and sodium hydroxide were dissolved in deionized water (the molar ratio of sodium carbonate and sodium hydroxide was 4:3; the solution was neutral after the theoretical reaction), and mixed alkali solution B was prepared. Add A dropwise to B in a constant temperature water bath at 40°C, and use a constant flow pump to control the drop rate to 2mL min -1 , stirring vigorously during the dropwise addition. After the dropwise addition, the pH of the above suspension was adjusted to 10 with 3M NaOH solution, and the stirring and crystallization was continued in a constant temperature water bath at 65° C. for 18 h to obtain a precipitate. After the steps of suction filtration, washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com