Preparation method of porous spherical silicon-based composite negative electrode material

A negative electrode material, porous spherical technology, applied in the field of preparation of porous spherical silicon-based composite negative electrode materials, can solve the problems of reduced material tap density, reduced theoretical capacity of composite materials, etc., to improve conductivity, improve electrochemical performance, change The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

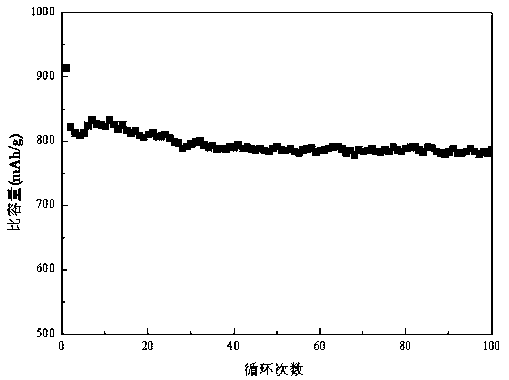

Embodiment 1

[0033] Prepare 2 mol / L NiCl 2Aqueous solution, take 200ml of the solution into the reaction bottle, add 3g of glucose, stir to dissolve, then take 14g of aluminum-silicon alloy powder with a silicon content of 20%, add it to the reaction bottle, and pass high-purity gaseous tetrachloride tetrachloride under continuous stirring conditions For silicon, the gas flow rate is controlled at 0.01mol / min, and the ventilation time is 50 minutes. Silicon tetrachloride is hydrolyzed in water to generate HCl and SiO 2 , with the increase of the amount of silicon tetrachloride, a large amount of HCl is generated to gradually dissolve and remove the aluminum in the aluminum-silicon alloy to obtain a porous silicon skeleton, and at the same time, the generated SiO 2 Deposition coating on the surface of porous silicon skeleton to form Si / SiO 2 matrix; add ammonia water dropwise to the above mixture, adjust the pH to 7~8, continue to stir for 10 minutes, then transfer it to a polytetrafluoroe...

Embodiment 2

[0036] Configure 1mol / L FeCl 3 Aqueous solution, take 200ml of the solution into the reaction bottle, add 2.85g of sucrose, stir to dissolve, then take 28g of iron-silicon alloy powder with a silicon content of 30%, add it to the reaction bottle, and feed high-purity gaseous tetrachloride under continuous stirring conditions SiO, the gas flow rate is controlled at 0.02mol / min, the ventilation time is 60 minutes, and silicon tetrachloride is hydrolyzed to generate HCl and SiO 2 , with the increase of the amount of silicon tetrachloride introduced, a large amount of HCl is generated to gradually dissolve and remove the iron in the iron-silicon alloy to obtain a porous silicon skeleton, and at the same time the generated SiO 2 Deposition coating on the surface of porous silicon skeleton to form Si / SiO 2 Matrix; add ammonia water dropwise to the above mixture, adjust the pH to 7~8, continue stirring for 10 minutes, then transfer it to a polytetrafluoroethylene-lined autoclave, ke...

Embodiment 3

[0039] Configure 0.5mol / L TiCl 4 Aqueous solution, take 200ml of the solution into the reaction bottle, add 3.2g of citric acid, stir to dissolve, then take 47g of silicon-magnesium alloy powder with a silicon content of 30%, add it to the reaction bottle, and introduce high-purity gaseous tetrachloride under continuous stirring conditions. Silicon chloride, the gas flow rate is controlled at 0.05mol / min, and the ventilation time is 10 minutes. Silicon tetrachloride is hydrolyzed to generate HCl and SiO 2 , with the increase of the amount of silicon tetrachloride, a large amount of HCl is generated to gradually dissolve and remove the magnesium in the magnesium-silicon alloy to obtain a porous silicon skeleton, and the SiO produced at the same time 2 Deposition coating on the surface of porous silicon skeleton to form Si / SiO 2 Matrix; add ammonia water dropwise to the above mixture, adjust the pH to 7~8, continue stirring for 10 minutes, then transfer it to a polytetrafluoroe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com