Synthesis and application of graphite phase carbon nitride-ammonium tungsten bronze composite photocatalyst

A graphite phase carbon nitride and phase carbon nitride technology, which is applied in the direction of physical/chemical process catalysts, optics, optical components, etc., can solve the problems of complex preparation process and unfavorable large-scale application, and achieve simple operation and improved photocatalysis Activity, effect of promoting mutual transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

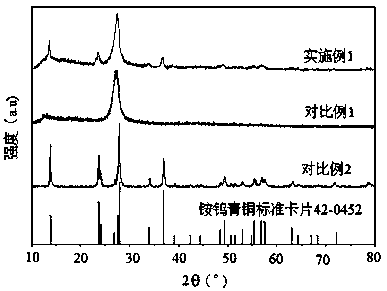

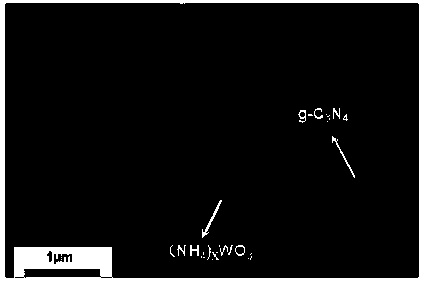

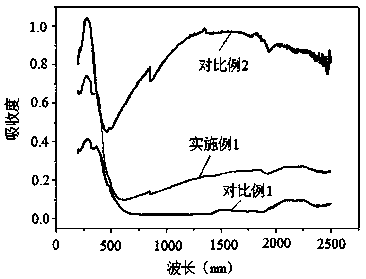

Embodiment 1

[0029] Take 10g of melamine and put it into a muffle furnace, heat up to 550°C at a heating rate of 2.2°C / min, keep it warm for 3 hours, and cool to room temperature to obtain a yellow solid, which is ground; The heating rate was increased to 550°C, and the temperature was kept for 3 hours to obtain the product; a mixed solution was prepared with 30mL deionized water and 30mL 30% hydrogen peroxide with a mass percentage of 30mL, and 0.6g of the product was dispersed in the mixed solution, stirred for 10min, and transferred to hydrothermal In the still, keep it warm at 140°C for 10h; centrifuge the mixed solution with deionized water and ethanol in turn, wash, and dry to obtain graphite phase carbon nitride; dissolve 0.25g of ammonium paratungstate in 40mL of ethylene glycol, Stir magnetically for 40 minutes to obtain a light yellow transparent and uniform solution; cool to room temperature, add 20 mL of acetic acid, and stir for 20 minutes to make it evenly mixed; Centrifuge a...

Embodiment 2

[0049] Take 2g of thiourea and put it into a muffle furnace, heat it up to 500°C at a heating rate of 1°C / min, and keep it warm for 6 hours. After cooling down to room temperature, grind the yellow solid; Min heating rate to 500 ℃, heat preservation 6h; take 1g, dispersed in 20mL of 15% mass percent hydrogen peroxide and 10mL of deionized water mixed solution, after stirring for 20min, transferred to a hydrothermal kettle, at 120 ℃ for 12 hours; the mixture was centrifuged, washed, and dried with deionized water and ethanol in turn to obtain g-C 3 N 4 . Dissolve 0.2g of ammonium paratungstate in 20mL of ethylene glycol, and stir magnetically at 160°C for 60 minutes to obtain a light yellow, transparent and homogeneous solution; cool to room temperature, add 10mL of acetic acid, stir for 10min to make it evenly mixed; then transfer to 100mL In a hydrothermal kettle, conduct a hydrothermal reaction at 140°C for 72 hours; successively wash the precipitate with deionized water a...

Embodiment 3

[0052] Take 15g of dicyandiamide into a muffle furnace, heat it up to 530°C at a heating rate of 5°C / min, and keep it warm for 2 hours. After cooling down to room temperature, grind the yellow solid; The heating rate of min was raised to 530°C, and the product was kept for 2 hours to obtain the product; 0.1g of the product was dispersed in a mixed solution composed of 50mL of 18% hydrogen peroxide and 40mL of deionized water, stirred for 30min, and then transferred to a hydrothermal kettle , kept at 160°C for 4h; the mixture was centrifuged, washed, and dried with deionized water and ethanol in turn to obtain g-C 3 N 4. Dissolve 0.6g of ammonium paratungstate in 60mL of ethylene glycol, stir magnetically at 210°C for 30min to obtain a light yellow, transparent and uniform solution; cool to room temperature, add 50mL of acetic acid, stir for 30min to make it evenly mixed; then transfer to 100mL of water In a hot kettle, at 180°C, hydrothermally react for 10 hours; successivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com