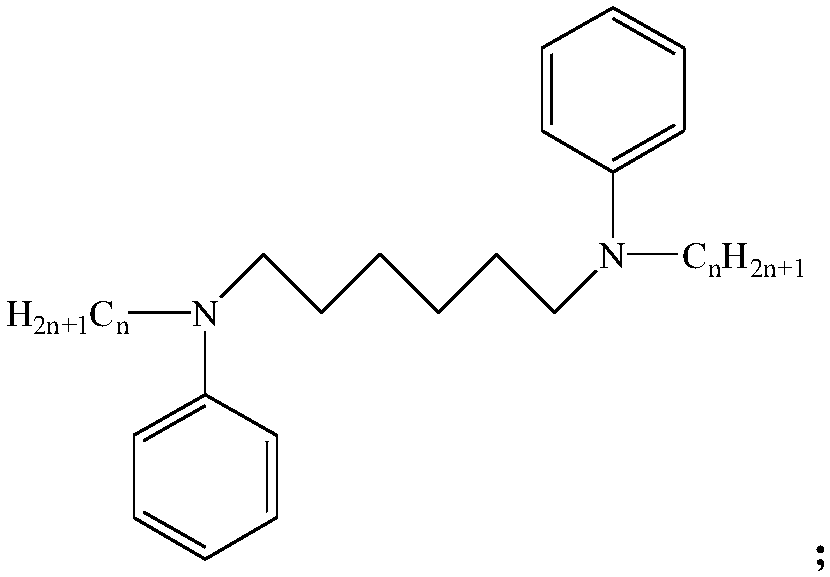

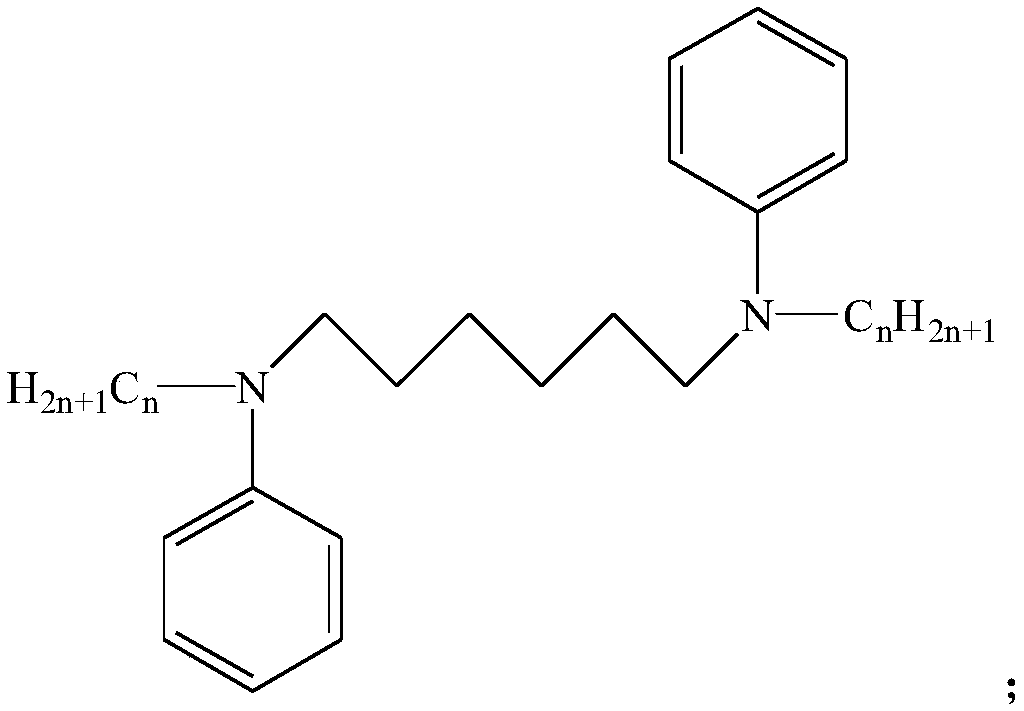

Temperature-resistant salt-resistant heavy oil emulsifying viscosity reducer and preparation method thereof

A technology of emulsification and viscosity reduction, temperature and salt resistance, applied in the field of viscosity reducers, to achieve the effect of clean process, no pollution, strong emulsifying and dispersing ability, and good salt resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

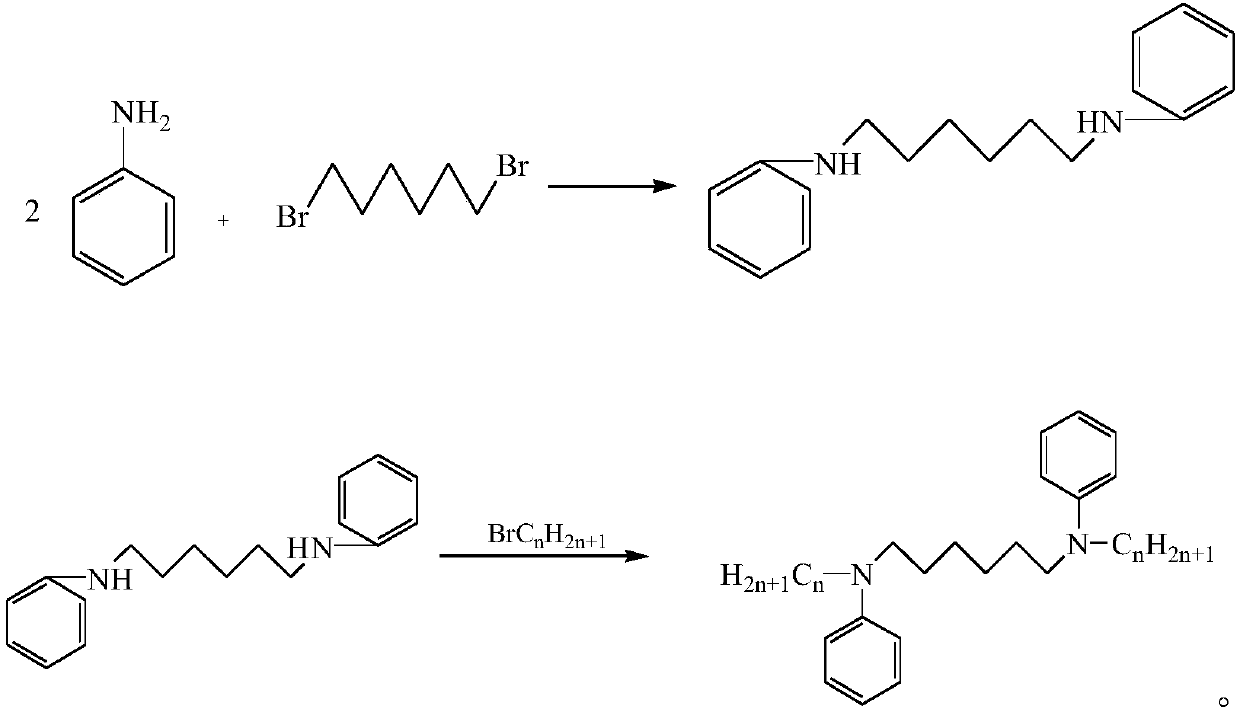

Embodiment 1

[0032] ①Add 244g of 1,6-dibromohexane and 186.2g of aniline to a three-necked flask equipped with a reflux condenser, and then add 244g of solvent absolute ethanol; heat up to 40°C, stir for 10min at a stirring rate of 200rpm, and wait for After complete dissolution, pour in condensed water, rapidly raise the temperature to 80°C under constant stirring rate, and reflux for 24 hours; after the reaction is completed, cool to room temperature to obtain the intermediate mixture;

[0033] ② Suction filter the above intermediate mixture to obtain a brown powder, wash twice with petroleum ether, and dry the obtained solid in a vacuum oven for 20 hours to obtain the intermediate N,N'-diphenylhexamethylenediamine;

[0034] ③ Put the above-mentioned intermediate N,N'-diphenylhexamethylenediamine into the three-necked flask again, then add 244g of solvent dimethyl sulfoxide and 24.4g of sodium hydroxide to the three-necked flask in turn, keep the temperature at 25°C, and stir The speed i...

Embodiment 2

[0039] ① Add 244g of 1,6-dibromohexane and 195.51g of aniline to a three-necked flask equipped with a reflux condenser, and then add 350g of absolute ethanol as a solvent; heat up to 50°C, stir for 20min at a stirring rate of 300rpm, and wait for After complete dissolution, pour in condensed water, rapidly raise the temperature to 83°C under constant stirring rate, and reflux for 28 hours; after the reaction is completed, cool to room temperature to obtain an intermediate mixture;

[0040] ② Suction filter the above intermediate mixture to obtain a brown powder, wash with petroleum ether for 3 times, and dry the obtained solid in a vacuum oven for 25 hours to obtain the intermediate N,N'-diphenylhexamethylenediamine;

[0041] ③ Place the above-mentioned intermediate N,N'-diphenylhexamethylenediamine into the three-necked flask again, then add 732g of solvent dimethyl sulfoxide and 48.8g of sodium hydroxide to the three-necked flask in turn, keep the temperature at 22°C, and sti...

Embodiment 3

[0046] ① Add 244g of 1,6-dibromohexane and 204.82g of aniline to a three-necked flask equipped with a reflux condenser, and then add 488g of absolute ethanol as a solvent; heat up to 55°C, stir at a stirring rate of 400rpm for 16min, and wait for After complete dissolution, pour in condensed water, rapidly raise the temperature to 85°C with constant stirring rate, and reflux for 36 hours; after the reaction is completed, cool to room temperature to obtain an intermediate mixture;

[0047] ② Suction filter the above intermediate mixture to obtain a brown powder, wash with petroleum ether 4 times, and dry the obtained solid in a vacuum oven for 40 hours to obtain the intermediate N, N'-diphenylhexamethylenediamine;

[0048] ③ Place the above-mentioned intermediate N,N'-diphenylhexamethylenediamine into the three-necked flask again, then add 500g of solvent dimethyl sulfoxide and 73.2g of sodium hydroxide to the three-necked flask in turn, keep the temperature at 25°C, and stir T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com