Composite solid propellant based on aluminum powder coated with nitramine oxidant and preparation method

A solid propellant and oxidant technology, applied in offensive equipment, explosive processing equipment, compressed gas generation, etc., can solve the problems of reducing propellant combustion efficiency, intensifying the erosion and ablation of the insulation layer, and engine two-phase flow loss, etc. Achieve the effects of inhibiting adverse effects, reducing content, and increasing energy levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation process of the embodiment can be divided into the following three steps:

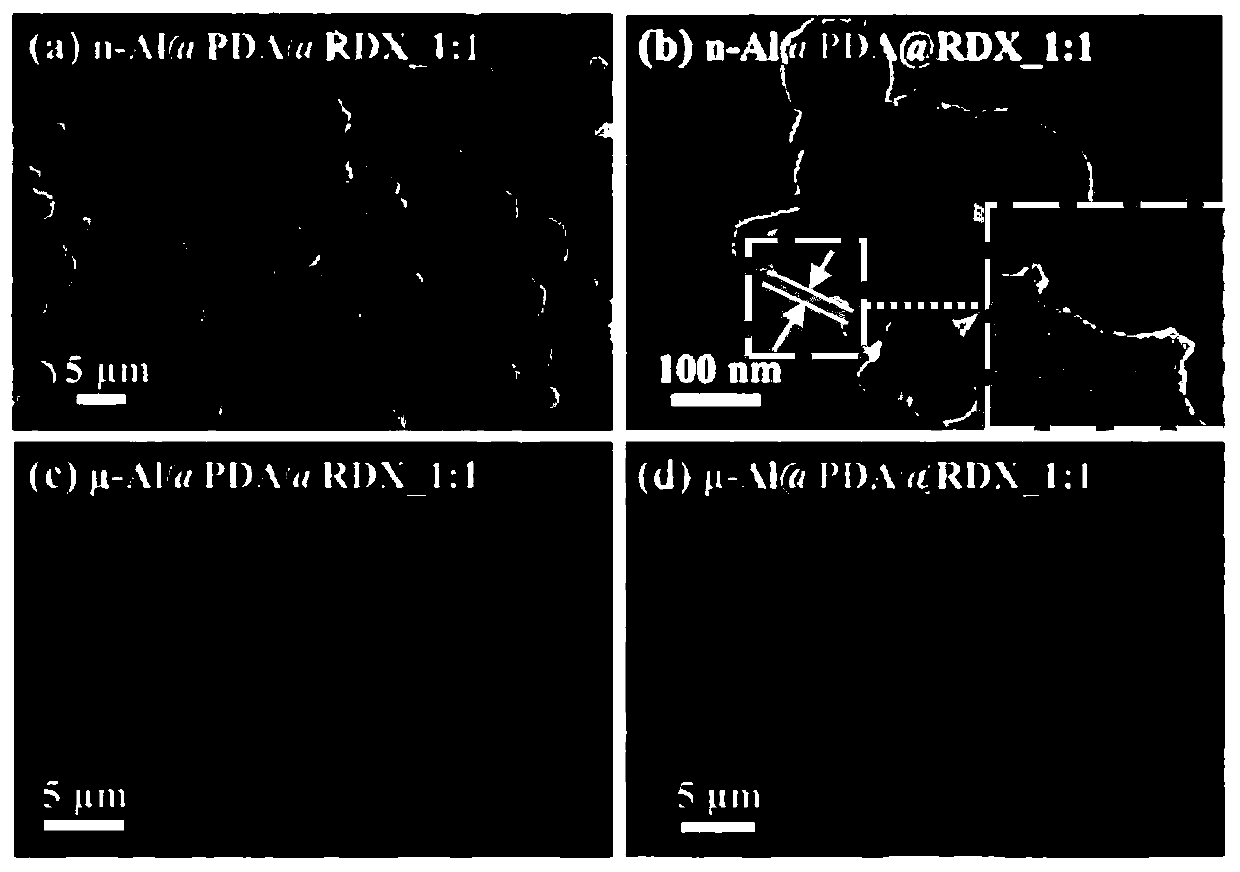

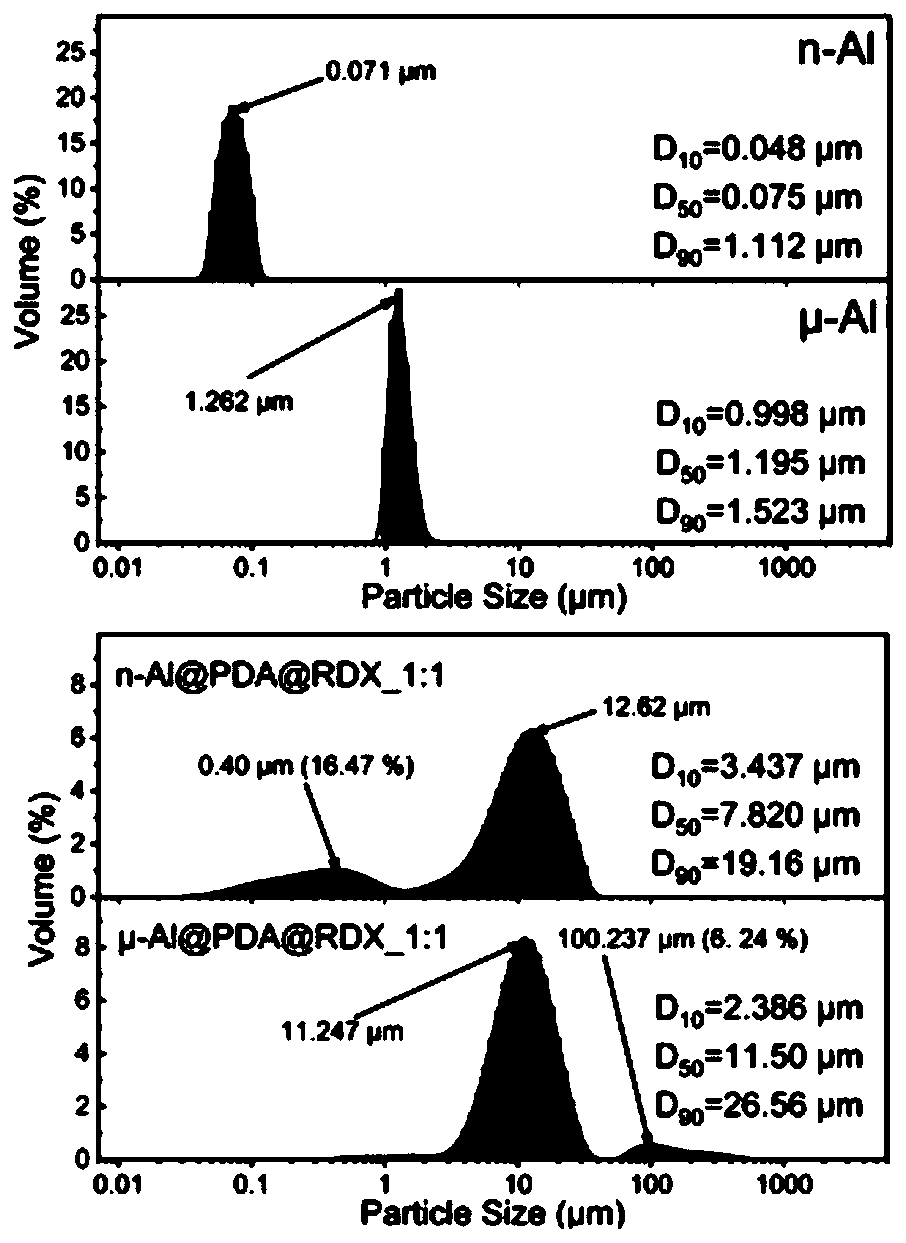

[0031] (1) Preparation of polydopamine surface-modified aluminum powder: Add 0.36g dopamine and 0.2g TRIS buffer solution (PH=8.5) into 200ml of distilled water, stir for 10min to partially polymerize dopamine molecules, and then add 3.6g of μ -Al (1-2 μm) and stirred for 1 h to make polydopamine grow in situ on the surface of aluminum powder to form a polydopamine layer, and dry the solution to obtain aluminum powder μ-Al@PDA whose surface is uniformly coated with polydopamine; it should be noted that , the content of PDA in μ-Al@PDA is less than 0.5wt%, so its mass is negligible for the entire propellant formulation, and the mass ratio of Al and RDX in the microspheres can be considered to be 1:1;

[0032] (2) Preparation of aluminum powder microspheres coated with nitramine oxidant: Dissolve 5.0 g of RDX in 25 ml of dimethyl sulfoxide (DMSO) solution, then add the same mass of ...

Embodiment 1

[0035] Example 1: A composite solid propellant without a burning rate catalyst. Wherein binder adopts hydroxyl-terminated polybutadiene (HTPB), and content is 12wt%; Plasticizer adopts diisooctyl sebacate (DOS), and content is 2wt%; Curing agent adopts isophorone diisocyanate ( IPDI), content is 1wt%; μ-Al content is 18wt%; RDX content is 18wt%; Ammonium perchlorate (AP) content is 49wt%; The theoretical specific impulse of this formula is 2567m s -1 . Concrete propellant preparation method is as follows:

[0036] 1) Raw material treatment: put the solid material in an oven at 60°C and dry for 96-120 hours;

[0037] 2) Weighing and mixing: weigh 100g of each component according to the formula, and stir for 120min in a water bath at 40-50°C to make a composite propellant slurry;

[0038] 3) Vacuum pouring: Vacuum pour the propellant slurry into the customized mold, and the vacuum pouring time is not less than 2 hours;

[0039] 4) Curing pharmaceutical strips: heating and cu...

Embodiment 2

[0041] Embodiment 2: Others are the same as in Embodiment 1, and all μ-Al is replaced by dopamine-surface-modified aluminum powder μ-Al@PDA of the same quality;

[0042] From image 3 It can be seen that the AP, RDX and μ-Al@PDA particles in Example 2 are also randomly distributed in the binder system, and there is no interfacial contact between the components; the apparent density of Example 2 is 1.69 g cm -3 , the heat of reaction is 5.42kJ·g -1 , with an energy density of 9.15kJ cm -3 (Table 2). The pressure index of embodiment 2 is 0.236, has increased 51% (table 3) compared with embodiment 1; From Figure 5 It can be seen that the particle size distribution of the condensed phase combustion products also presents a trimodal distribution, and the particle size of the largest aggregate is ~70.9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com