Method for removing methanol in ethanol

A technology of methanol and ethanol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as insignificant effect of azeotropic distillation, loss of liquor flavor, difficult operation, etc., to achieve a wide range of applications, Low cost, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Melting to prepare CaMg 2 alloy, the steps are as follows:

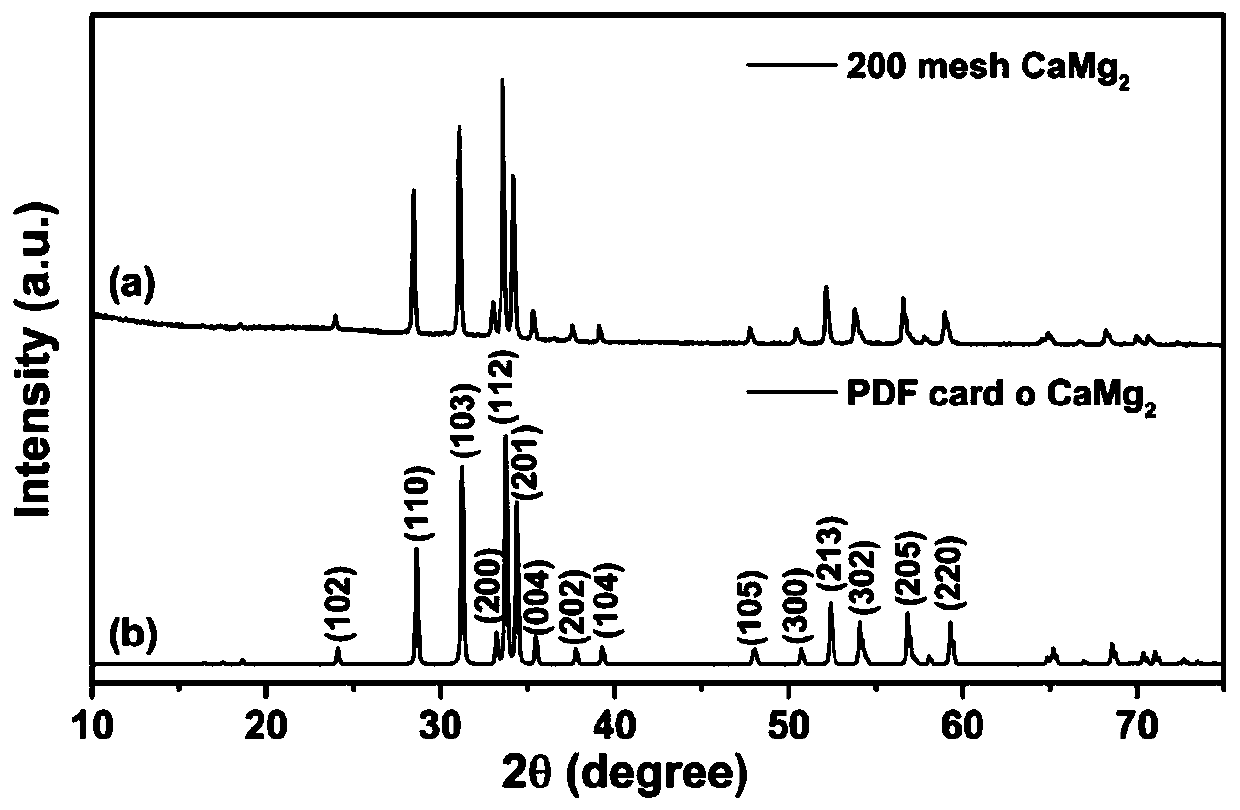

[0036] Under the atmosphere of 0.1MPa argon gas, the magnesium block with a purity of more than 99% and the calcium block with a purity of 95% are packed into a well-sealed pure iron tube with a material ratio of 2:1, and placed in a resistance furnace And kept at 900°C for 20h, cooled with the furnace, and then the obtained Mg-Ca alloy was crushed in an argon atmosphere glove box and passed through a 200-mesh sieve. The XRD pattern was similar to that of CaMg 2 PDF comparisons like figure 1 shown by figure 1 It can be seen that the obtained broken Mg-Ca alloy is high-purity CaMg 2 alloy powder.

Embodiment 2

[0038] Preparation of refined CaMg by ball milling 2 Alloy powder, the steps are as follows:

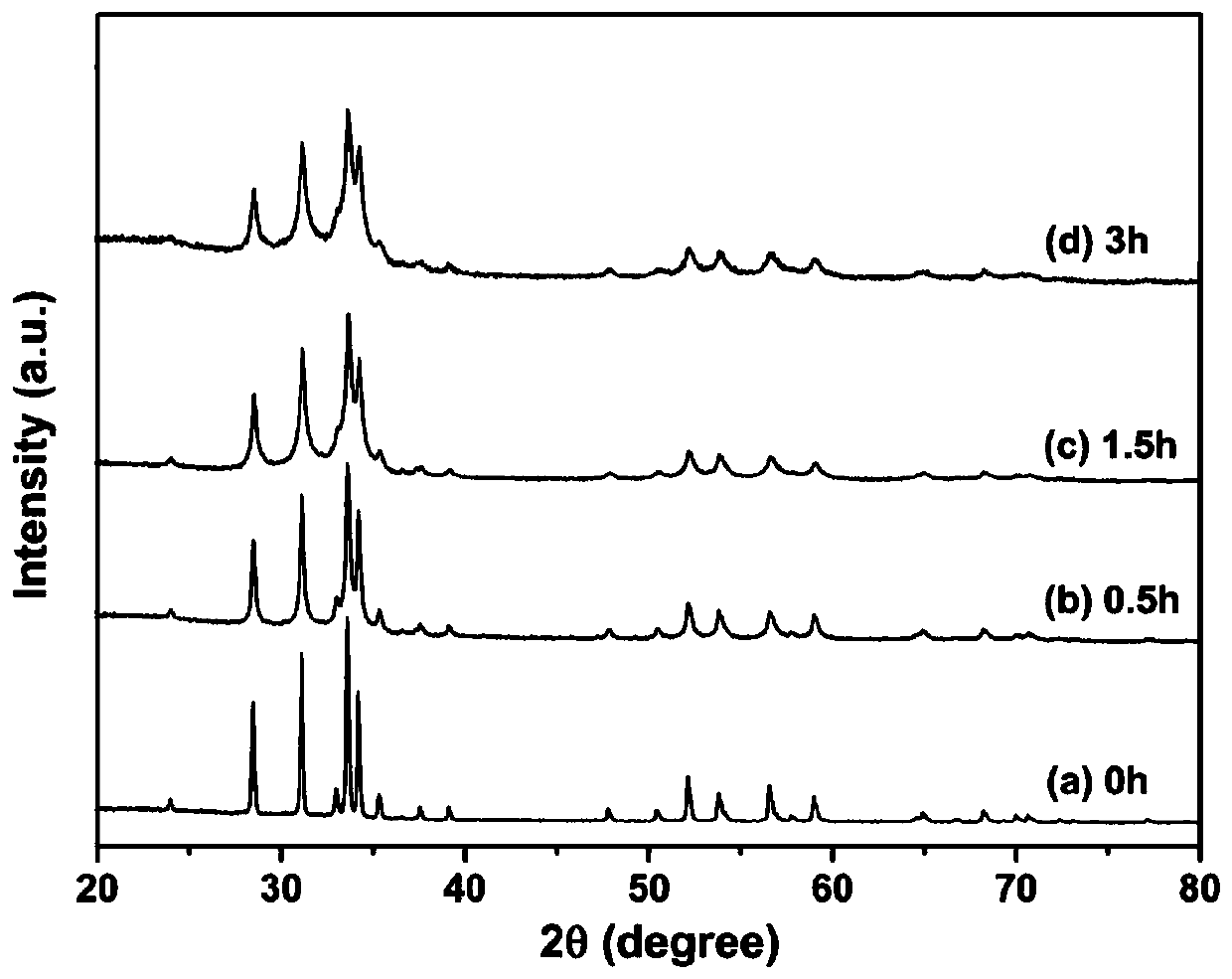

[0039] Under room temperature, in the glove box of 0.1MPa argon gas atmosphere, get the 200 order CaMg that above-mentioned embodiment 1 prepares 2 The alloy powder was put into a ball mill jar and sealed, and then placed (volume about 200ml) in a planetary ball mill (QM-3SP4) for ball milling, the ball-to-material ratio was 30:1, the ball milling speed was 400 rpm, and the ball milling time was 0.5-3h, the operation mode is alternating positive and negative intermittent operation, each time running for 30 minutes and then stopping for 30 minutes, so alternately.

[0040] CaMg after ball milling 2 The XRD pattern of the alloy powder is as follows figure 2 As shown, comparing the diffraction peaks of raw materials, it can be seen that the powder obtained by ball milling at different times is still CaMg 2 , but the diffraction peaks become wider and weaker, which means that the gr...

Embodiment 3

[0042] CaMg 2 The alcoholysis reaction of alloy powder in alcohol solution, the steps are as follows:

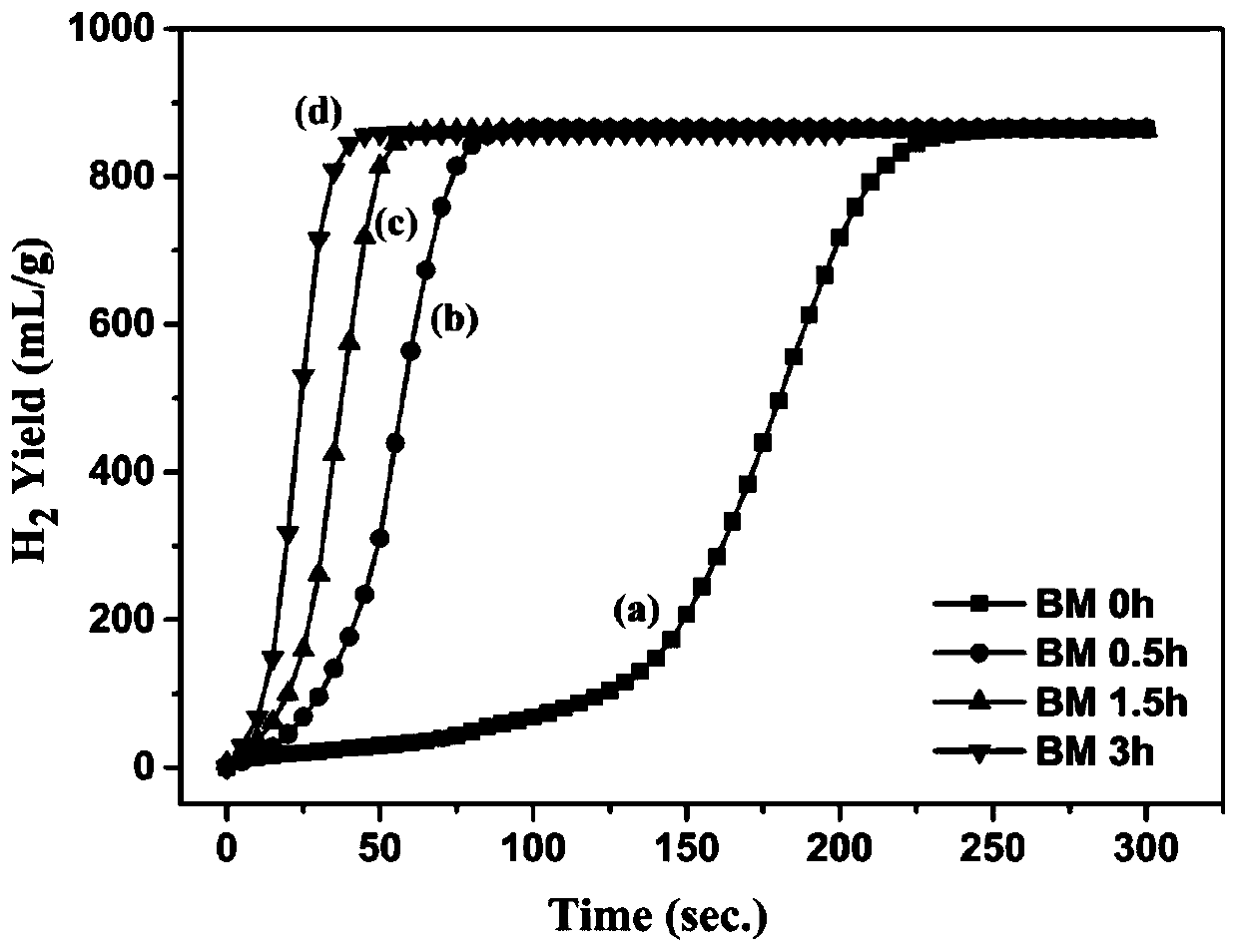

[0043] At room temperature, in a glove box with 0.1MPa argon atmosphere, take 0.1g of 200 mesh sieved CaMg 2 The alloy powder is placed in a reaction bottle, and alcoholysis reaction is carried out with 10ml methanol at room temperature, and the reaction kinetic curve is as follows: image 3 As shown in the curve (a) in the reaction, there is an induction period of about 2 minutes at the beginning of the reaction, and then the alcoholysis reaction rate is accelerated, reaching the maximum at 3 minutes, and the hydrogen production rate is 702ml g -1 min -1 Hydrogen, the CaMg 2 The alloy powder can be completely reacted within 5 minutes, and the final hydrogen release amount is 864ml·g -1 hydrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com