Brominated chlorinated polybutadiene/styrene flame retardant and preparation method and application thereof

A technology of brominated chlorinated polybutadiene and styrene, applied in the field of flame retardants, can solve the problems of deterioration of product performance, side reactions, large amount of waste water, etc., and achieves high flame retardant efficiency and good flame retardant efficiency , the effect of improving the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

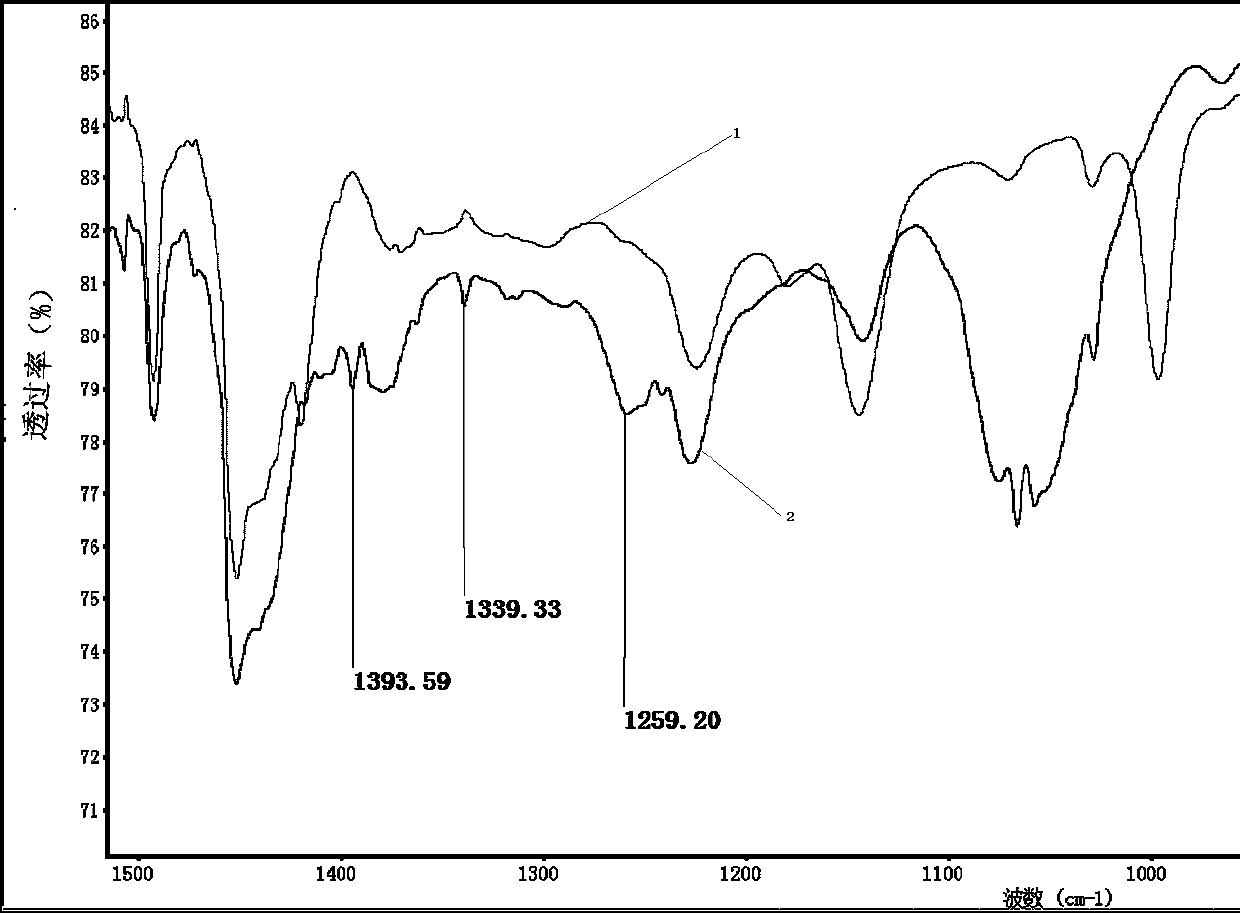

[0074] After partial bromination of SBS, the solution was chlorinated under conditions containing tetrabutylammonium bromide.

[0075] Include the following steps:

[0076] (1) Dissolution of brominating agent

[0077] The brominating agent tetrabutylammonium tribromide (TBAB.Br 2 ) 25.64kg, dichloromethane (DCM) 100kg into a 500L dissolving tank to form a wine red brominating agent solution.

[0078] (2) Dissolution of SBS

[0079] Add 5kg of SBS and 100kg of DCM into a 500L reactor at room temperature to obtain a SBS solution.

[0080] (3) Dropping

[0081] At low temperature (-5°C), add the brominating agent solution to the SBS solution dropwise at a rate of 1 l / min. After the dropwise addition, keep warm at -5°C for 8 hours, and keep warm at room temperature (20°C) for 16 hours.

[0082] (4) Pass chlorine gas

[0083] 0.5 kg of chlorine gas was passed in at -5°C, and after the chlorine gas was passed through, the temperature was continued for 30 minutes; the rate of...

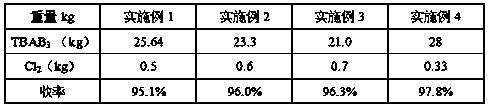

Embodiment 2-4

[0090] Embodiment 2-4 is on the basis of embodiment 1, only changes the add-on of tetrabutylammonium tribromide, chlorine, and other conditions remain unchanged.

Embodiment 5

[0102] Embodiment 5 Application of brominated chlorinated SBS prepared by the present invention in styrene resin

[0103] testing method:

[0104] Flame retardancy: Tested according to GB8624-2006.

[0105] The thermal conductivity measuring instrument is a thermal conductivity measuring instrument, which is tested according to the national standard GB / T10294-2008.

[0106] The styrenic polymer resin used is general-purpose polystyrene GPPS, and its weight-average molar mass Mw is: 25000-50000 g / mol, preferably 280000-450000 g / mol. The mixing and extrusion in the following comparative examples and examples were all carried out in an extruder.

[0107] Polystyrene, Mw=410000g / mol: Shanghai Secco Petrochemical Co., Ltd.;

[0108] Ba(NO 3 ) 2 Modified graphite, self-made. Among them, flake graphite is selected as the graphite matrix, Qingdao Tianshengda Graphite Co., Ltd.;

[0109] Foaming agent pentane and flame retardant hexabromocyclododecane are commercially available....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com