Crude copper blowing process

A blister copper and process technology, applied in the field of blister copper blowing process, can solve the problem of low recovery rate of blister copper, and achieve the effects of meeting environmental protection, increasing reduction rate, and strengthening reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

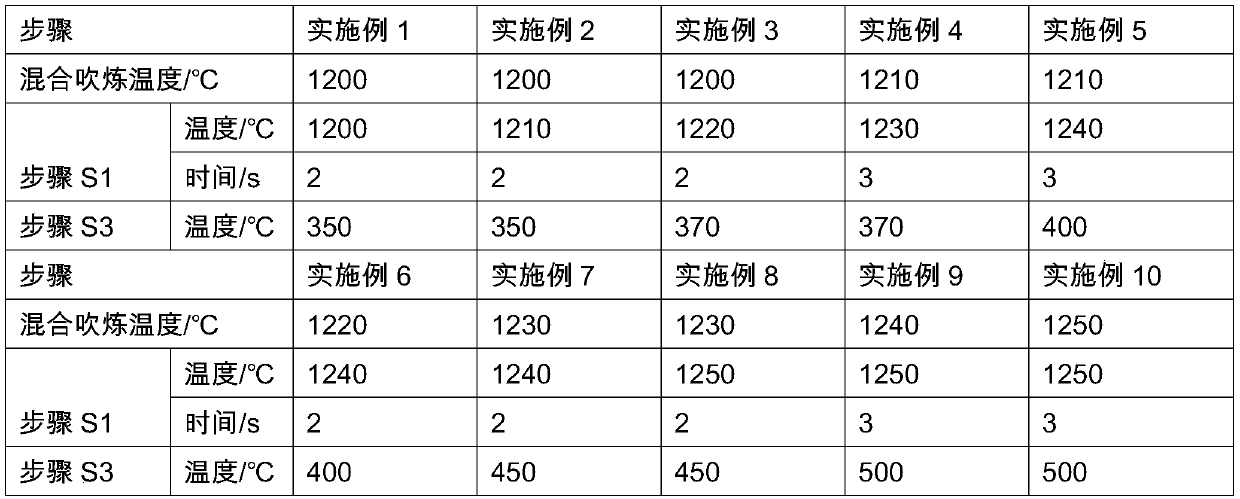

Examples

Embodiment 1

[0043] A blister copper blowing process, comprising the steps of:

[0044] The tailings of brass and brass incinerated in a rotary kiln and the tailings of hazardous waste incinerated in a rotary kiln are mixed and put into a side blowing melting furnace for smelting, and limestone, quartz stone, iron oxide, blue At the same time, oxygen is blown into the charcoal, and it is mixed and blown at 1200°C; the blowing process consists of two stages. In the first stage, the oxide formed by iron oxidation is immediately dissolved in the melt, and with the boiling of the melt and Solid or dissolved quartz flux floating on the surface of the molten pool contacts slagging. The end point of slagging is to observe the furnace mouth, the floating edge of the flue gas descends, the airflow is active, and the surroundings overflow out of the smoke hood in a tumbling shape. At the same time, the flame changes from orange to yellow-green, and then to gray. The flame is powerful and the brightn...

Embodiment 2

[0080]The difference between embodiment 2 and embodiment 1 lies in the difference in the addition amount of each raw material and the difference in process parameters.

Embodiment 3

[0082] The difference between embodiment 3 and embodiment 1 lies in the difference in the addition amount of each raw material and the difference in process parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com