Preparation process of novel magnetized three-stage fermentation organic fertilizer

A three-stage fermentation and organic fertilizer technology, which is applied in the field of organic waste resource utilization, can solve the problems that the fertilizer efficiency of organic fertilizers cannot reach the expected results, organic components are prone to mineralization, and biological fungi cannot be fully transformed, etc. And less harmful substances, rich in organic nutrition, reducing the effect of antibiotics and other residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

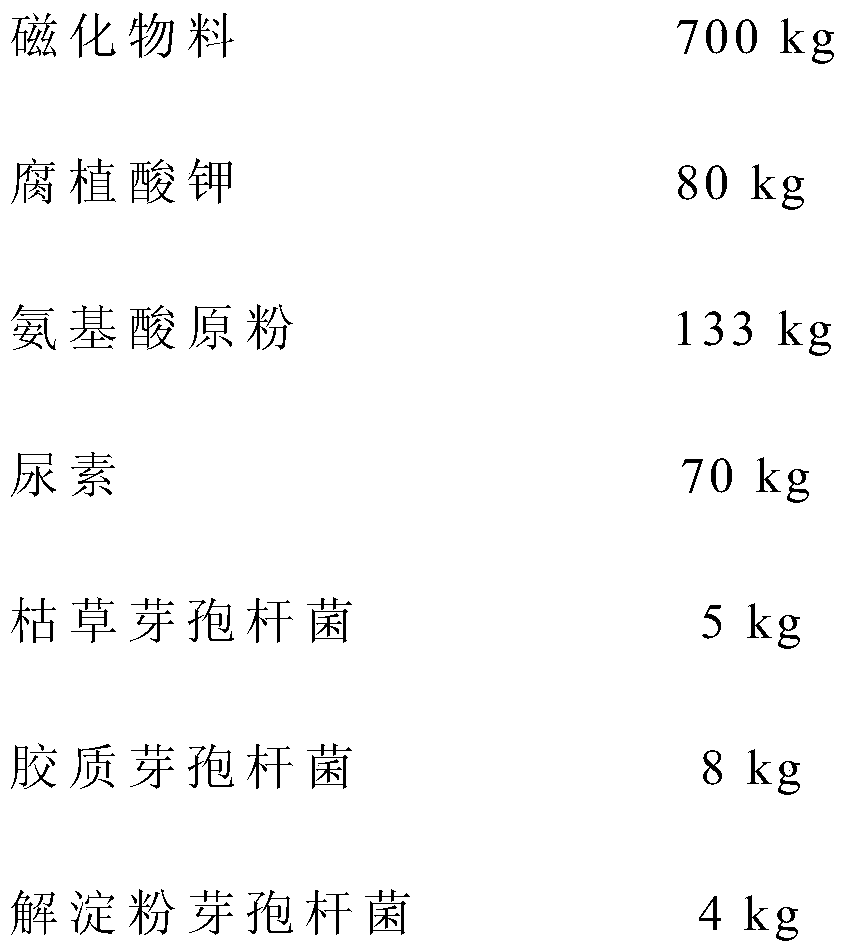

Embodiment 1

[0029] (1) Fermentation process: Mix the organic waste with a mass ratio of 100:0.5 and the organic material decomposing agent as the fermentation substrate, and put it into the fermentation tank. The length of the fermentation tank is 20m, the width is 8m, and the height is 2m;

[0030] Turn on the heating device of the fermentation tank to start fermentation, turn off the heating device when the temperature of the material reaches above 40°C, and turn over the material every day to observe the temperature change of the fermentation material. If the temperature of the material exceeds 70°C, immediately turn over and cool down. , when the fermented material enters the cooling stage, when the maximum temperature is below 50°C, the material is exported and used as fermented material for standby; use of organic waste: 500 parts of sheep manure, 200 parts of chicken manure, 300 parts of mushroom dregs; decomposing agent for organic materials Requirements: effective viable count ≥ 0...

Embodiment 2

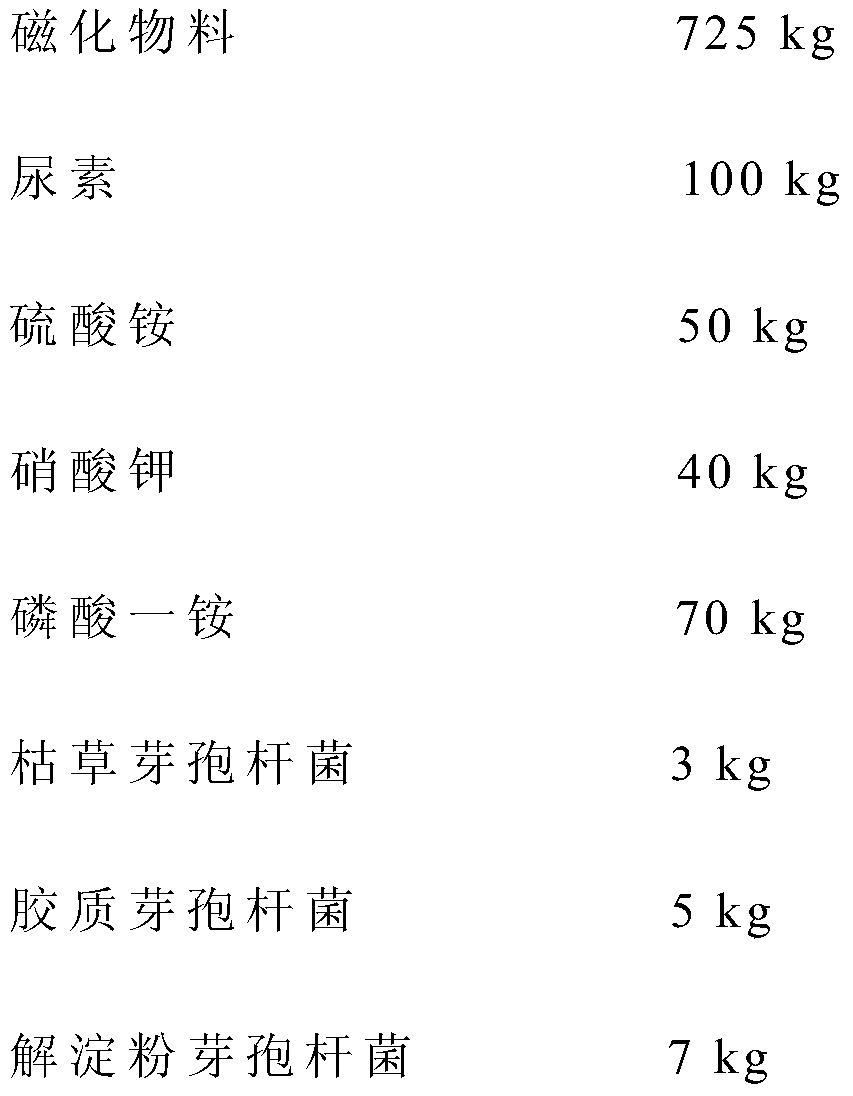

[0039] (1) Fermentation process: Mix organic waste with a mass ratio of 100:0.3 and an organic material decomposing agent as a fermentation substrate, and put it into a fermentation tank. The length of the fermentation tank is 20m, the width is 8m, and the height is 2m; open The heating device of the fermentation tank starts to ferment. When the temperature of the material reaches 40°C, the heating device is turned off. The material is turned over and thrown every day to observe the temperature change of the fermentation material. When the fermented material enters the cooling stage and the maximum temperature is below 50°C, the material is exported and used as a fermented material for standby; the organic waste is prepared according to the following weight ratio: 250 parts of straw, 180 parts of chicken manure, and 570 parts of pig manure; organic material decomposing agent The requirements are that the number of effective viable bacteria is ≥ 0.5 billion, the cellulase activi...

Embodiment 3

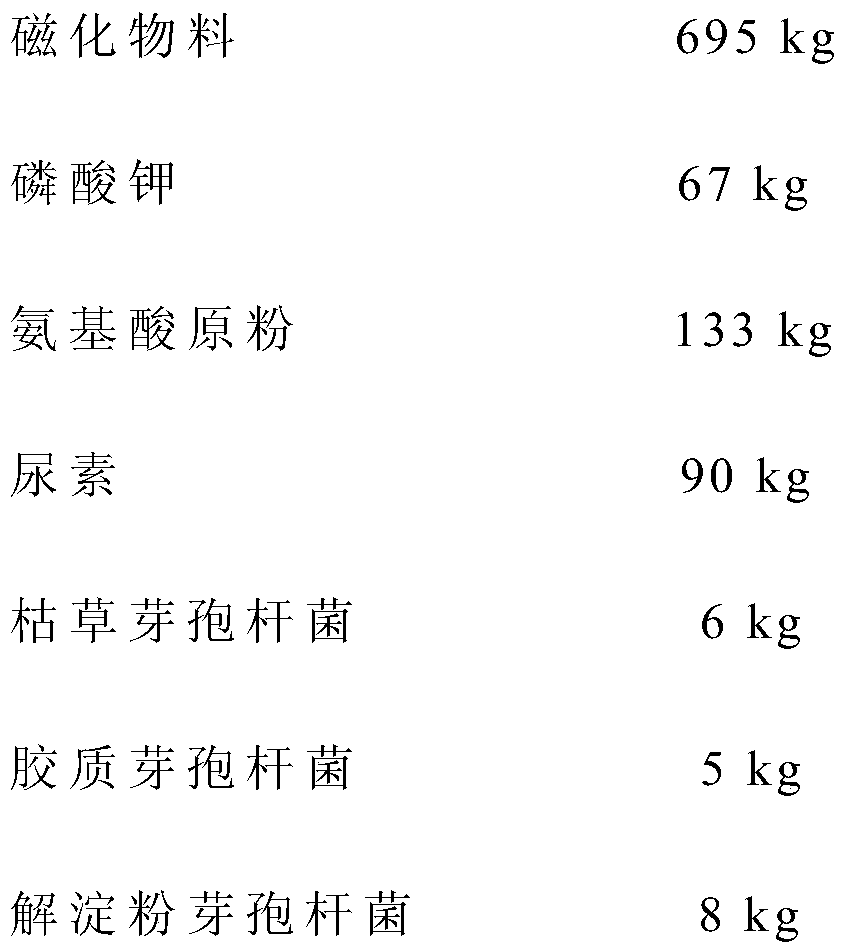

[0048] (1) Fermentation process: Mix organic waste with a mass ratio of 100:0.7 and an organic material decomposing agent as a fermentation substrate, and put it into a fermentation tank. The length of the fermentation tank is 20m, the width is 8m, and the height is 2m; open The heating device of the fermentation tank starts to ferment. When the temperature of the material reaches 40°C, the heating device is turned off. The material is turned over and thrown every day to observe the temperature change of the fermentation material. When the fermented material enters the cooling stage and the highest temperature is below 50°C, the material is exported and used as fermented material for standby; the organic waste is prepared according to the following weight ratio: 300 parts of cow dung, 100 parts of soybean meal, 300 parts of furfural residue, and 300 parts of sugar residue Parts; organic material decomposing agent requires effective viable count ≥ 0.5 billion, cellulase activity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com