Adsorbent, application of adsorbent to refining of dimethyl benzyl alcohol hydrogenolysis raw material co-produced by co-oxidation method, and method for refining dimethyl benzyl alcohol hydrogenolysis raw material co-produced by co-oxidation method in virtue of adsorbent

A technology of dimethylbenzyl alcohol and adsorbent, applied in the field of organic chemical industry, can solve the problems affecting process economy, poor catalyst stability, poor cumene selectivity, etc., and achieves improved reaction adsorption efficiency, stable properties, and prolonged adsorption time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

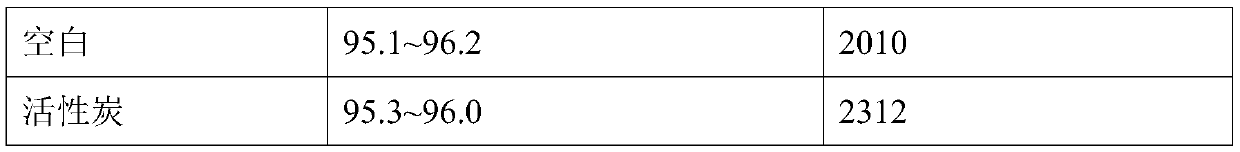

Embodiment 1

[0051] Five materials from sludge, SBA-15, graphene, γ-aminopropyl-triethoxysilane, and phenylpropionic acid produced by the wastewater biochemical system were mixed according to the mass ratio of 0.2:6:0.5:0.01:0.03. Stir at 60°C for 8h. Roast at 600°C for 140min in a nitrogen atmosphere in a tube furnace, wash with water until neutral, and dry at 105°C for 6h to obtain a carbon-based mesoporous silica carrier, which is defined as Adsorbent 1.

Embodiment 2

[0053] The sludge from the wastewater biochemical system, SBA-15, graphene, γ-aminopropyl-triethoxysilane, and phenylpropionic acid were mixed according to the mass ratio of 0.1:5.2:0.4:0.02:0.06. Stir at 60°C for 8h. Roast at 600°C for 160min in a nitrogen atmosphere in a tube furnace, wash with water until neutral, and dry at 105°C for 5h to obtain a carbon-based mesoporous silica carrier, which is defined as Adsorbent 2.

Embodiment 3

[0055] The sludge from the wastewater biochemical system, SBA-15, graphene, γ-aminopropyl-triethoxysilane, and phenylpropionic acid were mixed according to the mass ratio of 0.2:4.5:0.3:0.03:0.04. Stir at 60°C for 8h. Roast at 500°C for 150min in a nitrogen atmosphere in a tube furnace, wash with water until neutral, and dry at 105°C for 6h to obtain a carbon-based mesoporous silica carrier, which is defined as Adsorbent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com