Preparation method of activated calcium carbonate for high-filling-capacity bi-component silicone adhesive

A technology with active calcium carbonate and high filling content, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, non-polymer adhesive additives, etc., can solve the problem of unfavorable products that are difficult to meet the comprehensive needs of industrial production and application markets Quality stability, calcium carbonate flocculation and other issues, to achieve excellent fluidity, shorten the aging time, slow down the effect of the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

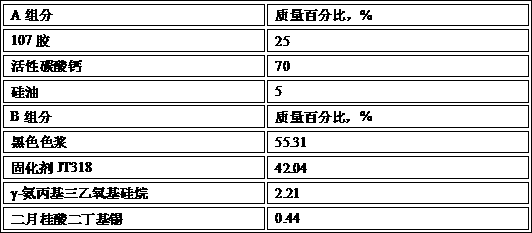

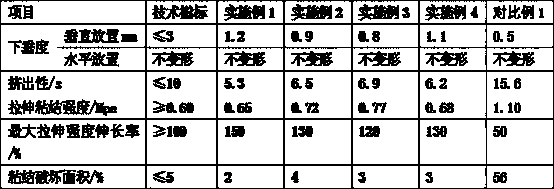

Examples

Embodiment 1

[0035] A preparation method of active calcium carbonate for high-filling two-component silicone rubber, comprising the steps of:

[0036](1) The limestone is crushed by a jaw crusher to a size of 2~3cm, calcined at 1100°C for 400 minutes to obtain quicklime, and then the quicklime and water are digested according to the gray-to-water mass ratio of 1:11 to obtain lime slurry, lime Pass the slurry through a 100-mesh sieve to remove waste residue, adjust the solid content of the lime slurry to 10.5%, and place the lime slurry for 48 hours for aging;

[0037] (2) Take 15kg of lime slurry and send it to the carbonation reaction tower, start the freezing cycle, adjust the temperature of the lime slurry to 29°C, add 1.5g of sucrose, start the stirring and freezing cycle, and when the system temperature reaches 29°C, turn off the freezing cycle and adjust The stirring rate is 1500r / min, and the mixed gas containing carbon dioxide is introduced to start the reaction. The carbon dioxide...

Embodiment 2

[0043] A preparation method of active calcium carbonate for high-filling two-component silicone rubber, comprising the steps of:

[0044] (1) The limestone is crushed by a jaw crusher to a size of 2~3cm, calcined at 1250°C for 350 minutes to obtain quicklime, and 2kg of quicklime is added to tap water at 25°C at one time according to the mass ratio of 1:11, and stirred for 20 minutes Finally, the lime slurry is passed through a 100-mesh sieve to remove waste residue, the solid content of the lime slurry is adjusted to 11.5%, and the lime slurry is aged for 48 hours;

[0045] (2) Take 15kg of lime slurry and send it to the carbonation reaction tower, start the freezing cycle, adjust the temperature of the lime slurry to 26°C, add 1.5g of sucrose, start the stirring and freezing cycle, and when the system temperature reaches 26°C, turn off the freezing cycle and adjust The stirring rate is 2000r / min, and the mixed gas containing carbon dioxide is introduced to start the reaction...

Embodiment 3

[0050] A preparation method of active calcium carbonate for high-filling two-component silicone rubber, comprising the steps of:

[0051] (1) The limestone is crushed by a jaw crusher to a size of 2~3cm, and calcined at 1150°C for 500 minutes to obtain quicklime. Add 2kg of quicklime to tap water at 25°C at one time according to the mass ratio of 1:10, and stir for 20 minutes. Finally, the lime slurry is passed through a 100-mesh sieve to remove waste residue, the solid content of the lime slurry is adjusted to 12.5%, and the lime slurry is aged for 24 hours;

[0052] (2) Take 15kg of lime slurry and send it to the carbonation reaction tower, start the freezing cycle, adjust the temperature of the lime slurry to 28°C, add 1.5g of sucrose, start the stirring and freezing cycle, and when the system temperature reaches 28°C, turn off the freezing cycle and adjust The stirring rate is 1500r / min, and the mixed gas containing carbon dioxide is introduced to start the reaction, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com