Preparation method of sodium p-nitrophenolate

A technology of sodium p-nitrophenolate and p-chloronitrobenzene, which is applied in the field of synthesis of fine chemical products, can solve the problems of complex separation and purification, low reaction conversion rate, and increased by-products, and achieve low energy consumption, uniform mixing and high efficiency , the effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

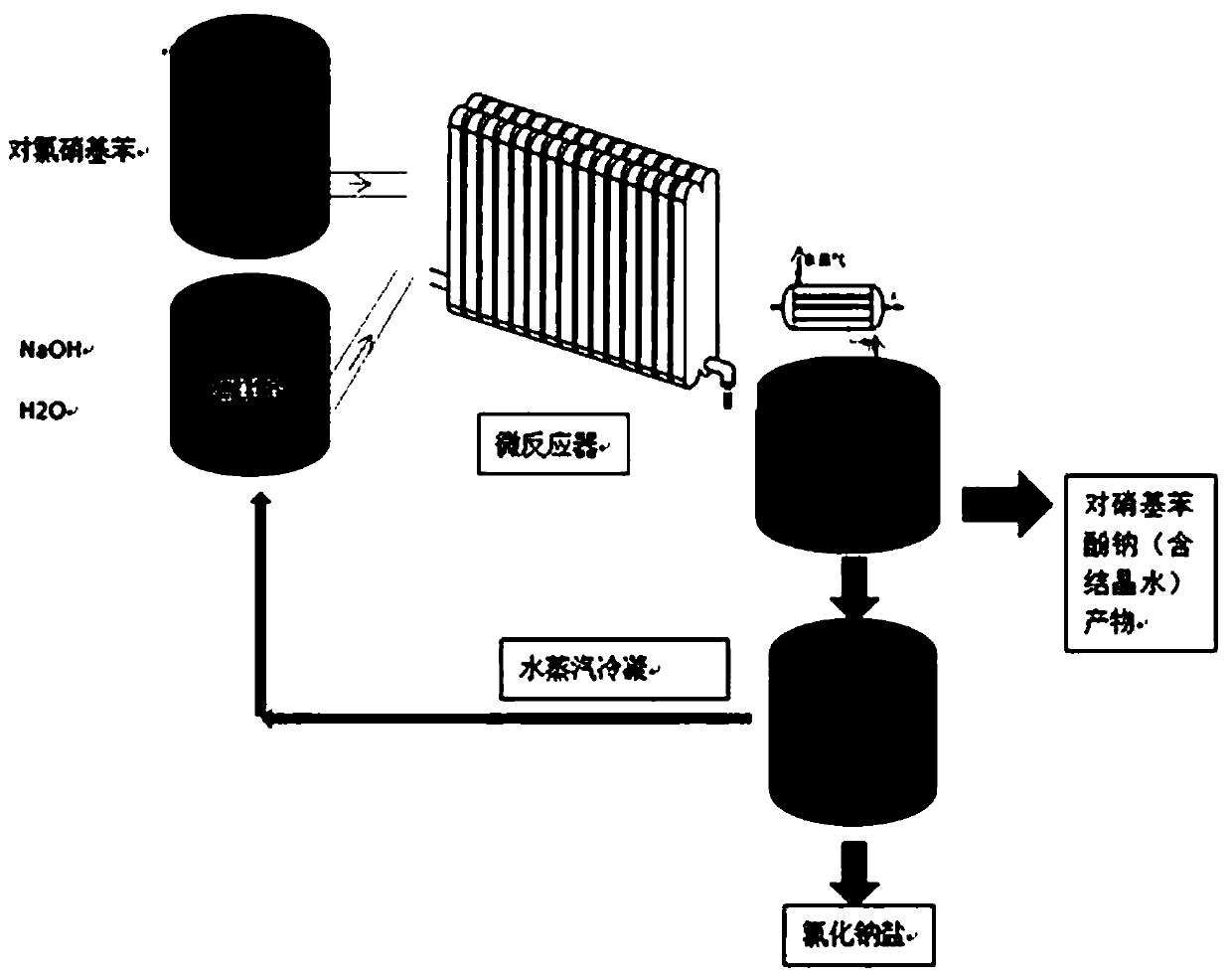

[0029] A preparation method of p-nitrophenol sodium salt, comprising the following steps:

[0030] a) Heat and melt 630Kg p-chloronitrobenzene in a melting tank, and at the same time prepare a 15% sodium hydroxide solution in a melting tank (320Kg sodium hydroxide is dissolved in 1800Kg water);

[0031] b) Before the reaction, nitrogen gas was introduced into the system repeatedly to replace the air for 3 times, and the heated and molten p-chloronitrobenzene and sodium hydroxide aqueous solution were pumped into the microreactor according to the mass ratio (6.3:21.2) and mixed evenly , to carry out high temperature and high pressure reaction, the specific conditions are: the nitrogen pressure is 4Mpa, the temperature is 150°C, and the residence time in the reaction system is 2h;

[0032] c) Transfer the reaction liquid to the cooling crystallization tank, the water in the heat exchanger of the cooling crystallization tank is heated and turned into steam, which can enter the ne...

Embodiment 2

[0034] A preparation method of p-nitrophenol sodium salt, comprising the following steps:

[0035] a) Heat and melt 630Kg of p-chloronitrobenzene in a melting tank, and at the same time prepare a 12% sodium hydroxide solution (352Kg of sodium hydroxide dissolved in 2581Kg of water) in a dissolution tank;

[0036] b) Before the reaction, nitrogen was introduced into the system repeatedly to replace the air for 5 times, and the heated and molten p-chloronitrobenzene and sodium hydroxide aqueous solution were pumped into the microreactor according to the mass ratio (6.3:29.3) and mixed evenly , to carry out high-temperature and high-pressure reaction, the specific conditions are: the nitrogen pressure is 6Mpa, the temperature is 160°C, and the residence time in the reaction system is 1h;

[0037] c) Transfer the reaction liquid to the cooling crystallization tank, the water in the heat exchanger of the cooling crystallization tank is heated and turned into steam, which can enter ...

Embodiment 3

[0039] A preparation method of p-nitrophenol sodium salt, comprising the following steps:

[0040] a) Heat and melt 630Kg p-chloronitrobenzene in a melting tank, and at the same time prepare a 25% sodium hydroxide solution (384Kg sodium hydroxide dissolved in 1152Kg water) in a dissolving tank;

[0041] b) Before the reaction, nitrogen gas was introduced into the system repeatedly to replace the air for 6 times, and the heated and molten p-chloronitrobenzene and sodium hydroxide aqueous solution were pumped into the microreactor according to the mass ratio (6.3:15.36) and mixed evenly , to carry out a high temperature and high pressure reaction, the specific conditions are: the nitrogen pressure is 8Mpa, the temperature is 180°C, and the residence time in the reaction system is 15min;

[0042] c) Transfer the reaction liquid to the cooling crystallization tank, the water in the heat exchanger of the cooling crystallization tank is heated and turned into steam, which can enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com