Synthesis device and synthesis method of iron oxide magnetic nano material

A technology of magnetic nanometer and synthesis device, applied in ferrous oxide, nanotechnology for material and surface science, iron oxide, etc., can solve the problems of expensive synthesis device, harsh synthesis conditions, insufficient oxidation, etc. Achieve the effects of fast magnetic separation and enrichment recovery, good biocompatibility, and controllable synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

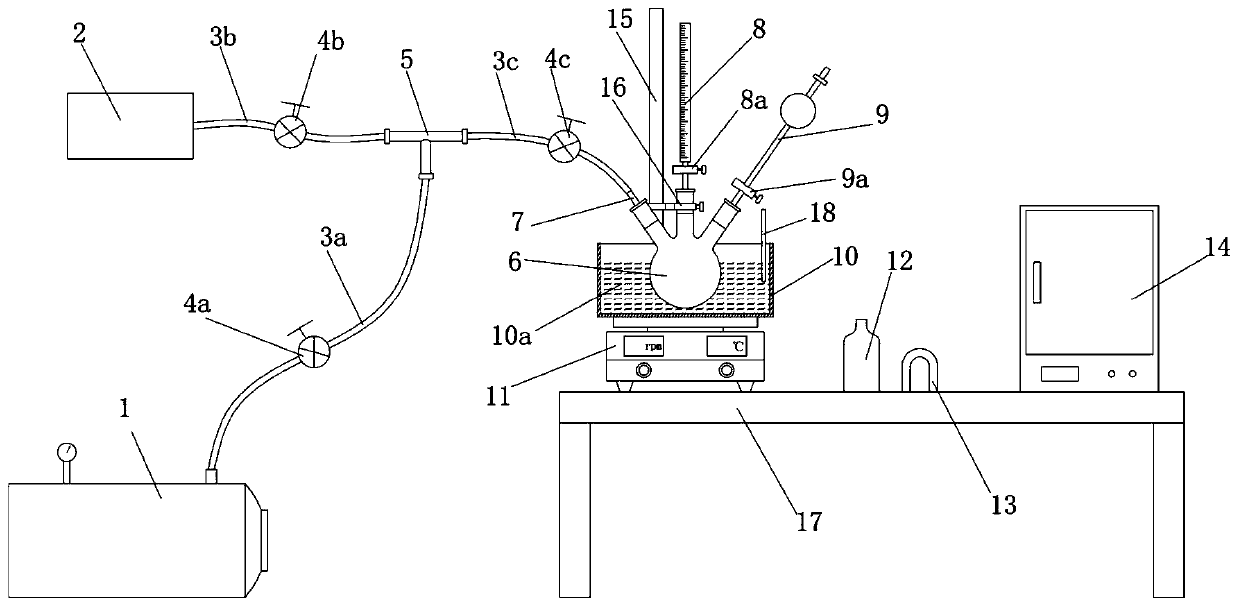

[0070] A kind of nano Fe that adopts above-mentioned synthesis device 3 o 4 Synthetic method, comprises the following steps:

[0071] (1) Nano Fe 3 o 4 Synthesis

[0072] Close the first valve 4a, the second valve 4b and the third valve 4c, connect the air bag filled with inert gas with the second hose 3b, dissolve the ferrous salt and the ferric salt with ultrapure water to obtain a mixed solution , Fe in the mixture 2+ and Fe 3+ The mol ratio is 1:2, the mixed solution is added to the separatory funnel 9, and the valve 9a of the separatory funnel 9 is closed simultaneously, and the outlet of the separatory funnel 9 is sealed with one of the inlets and outlets of the three-neck round bottom flask 6 , the burette is an alkaline burette, the alkaline liquid is added to the burette, and the valve 8a of the burette 8 is closed simultaneously, the outlet of the burette is sealed with another inlet and outlet of the three-necked round bottom flask 6, and the valve 9a of the s...

Embodiment 1

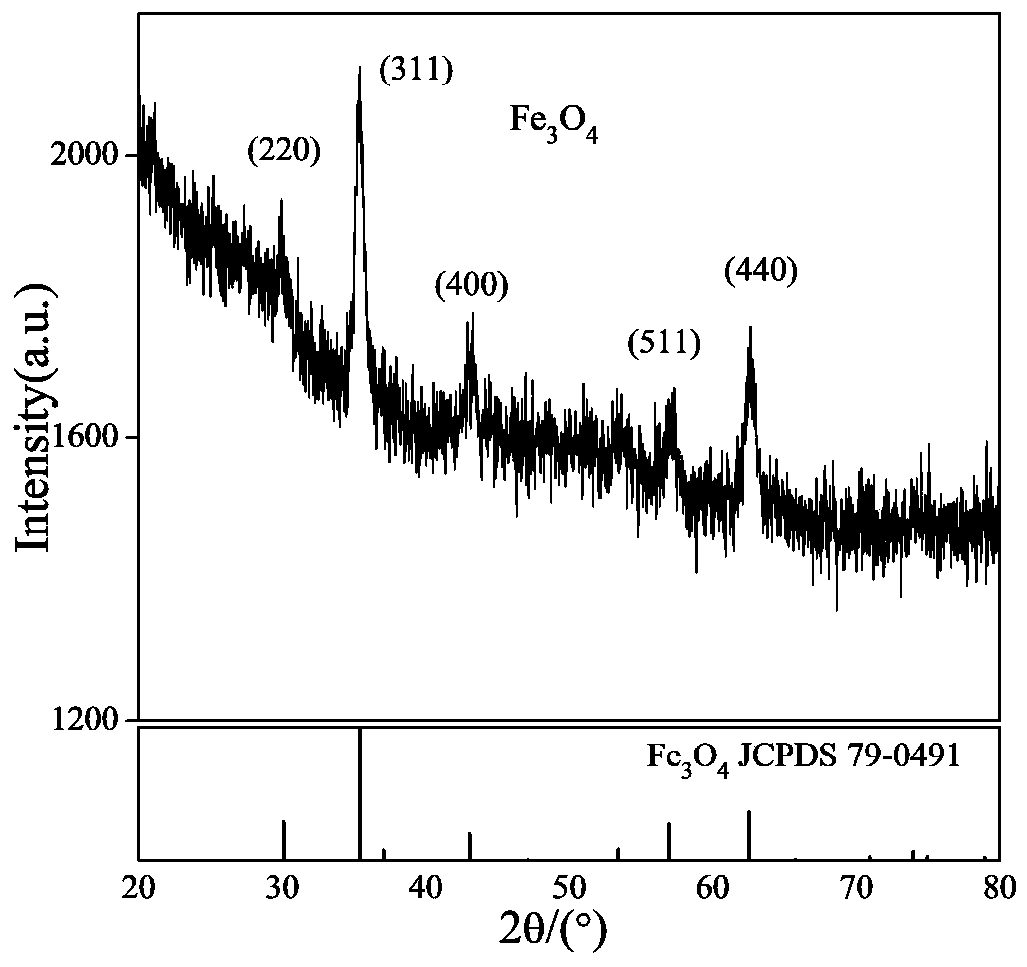

[0087] (1) Nano Fe 3 o 4 Synthesis

[0088] Close the first valve 4a, the second valve 4b and the third valve 4c, the air bag full of inert gas is connected with the second flexible pipe 3b, and 1g ferrous chloride tetrahydrate and 2.7g ferric chloride hexahydrate are used 50mL of ultrapure water was dissolved in a beaker to obtain a mixed solution, and Fe in the mixed solution 2+ and Fe 3+ The mol ratio is 1:2, the mixed solution is added to the separatory funnel 9, and the valve 9a of the separatory funnel 9 is closed simultaneously, and the outlet of the separatory funnel 9 is sealed with one of the inlets and outlets of the three-neck round bottom flask 6 , the burette is an alkaline burette, the concentration is 25%-28% ammonia water is added to the burette, and the valve 8a of the burette 8 is closed at the same time, the outlet of the burette is tightly connected with the other inlet and outlet of the three-neck round bottom flask 6, and the separating funnel is open...

Embodiment 2

[0093] (1) Nano α-Fe 2 o 3 Synthesis

[0094] Close the first valve 4a, the second valve 4b and the third valve 4c, connect the air bag filled with high-purity oxygen with the second hose 3b, and add pure water into the three-neck round bottom through the inlet and outlet of the three-neck round bottom flask 6 In the flask, the ferric salt solution is added to the separatory funnel 9, the ferric salt solution adopts ferric chloride hexahydrate solution, and the valve 9a of the separatory funnel 9 is closed simultaneously, and the outlet of the separatory funnel 9 is connected to the three One of the inlets and outlets of the round-bottomed flask 6 is tightly connected, and the burette is an acidic burette. The concentrated hydrochloric acid with a concentration of 37% is added to the burette, and the valve 8a of the burette 8 is closed at the same time. The inlet and outlet are sealed and connected, and the third hose is sealed and connected with the last inlet and outlet of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com