A kind of anticorrosion coating with high temperature resistance and high emissivity

A high radiation rate, anti-corrosion coating technology, applied in anti-corrosion coatings, fireproof coatings, coatings, etc., can solve the problems of low-temperature anti-corrosion and infrared radiation rate, poor anti-oxidation and corrosion performance, and use in medium and low temperature environments. Good infrared radiation performance, improved heat dissipation effect, good high temperature anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

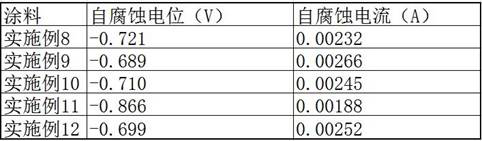

Examples

Embodiment 1

[0023] A high-temperature high-radiation resistant coating, is made of raw material of the following weight parts: 10 copies of cordierite micropowder, 6 parts of the tetraned iron oxide, 6 copies of chronic micro powder, 10 cobalt oxide fine powder, manganese iron spools 8 parts of stone micropowder, 20 borosilicate glass powder, 5 parts of low melting glass powder modified graphene, binding agent (silicone resin: water glass = 1: 1), polyethylene glycol 0.1 parts, fluorocarbon Surfactant 0.1, 0.2 parts of carboxymethylcellulose and 0.1 parts of silicone defoamer.

[0024] Cordierite micro powder, tetraned iron fine powder, chromium oxide fine powder, cobalt oxide fine powder, manganese iron tipline fine powder and borosilicate glass powder are less than 5 μm.

[0025] The preparation method of low melting glass powder modified graphene is as follows:

[0026] S1: Take a low melting point glass powder and the solvent is mixed with a solvent to obtain a dispersion to obtain a disp...

Embodiment 2

[0030] A high-temperature high-radiation anti-corrosion coating, made of raw materials of the following weight parts: 5 copies of the cordierite microfour, 4 parts of the four-chromium oxide, 2 copies of chromium oxide, 6 copies of cobalt fine powder, manganese iron spools 4 parts of stone micropowder, 15 borosilicate glass powder, 3 parts of low melting glass, 30 parts of the bonze, 30 parts of the binder, 0.1 parts of polyethylene glycol, 0.03 parts of fluorocarbon surfactant, carboxymethyl cellulose 0.15 0.05 parts of the silicone defoamer.

[0031] Cordierite micro powder, tetraned iron fine powder, chromium oxide fine powder, cobalt oxide fine powder, manganese iron tipline fine powder and borosilicate glass powder are less than 5 μm.

[0032] The preparation method of low melting glass powder modified graphene is as follows:

[0033] S1: Take a low melting point glass powder and the solvent is mixed with a solvent to obtain a dispersion to obtain a dispersion, and a deionize...

Embodiment 3

[0037] A high-temperature high-radiation resistant paint, made of raw materials of the following weight parts: 10 copies of cordierite microfour, 8 pieces of four-iron oxide, 6 copies of chromium oxide, 10 copies of cobalt oxide, manganese iron spools 10 parts of stone micropowder, 20 borosilicate glass powder, 5 parts of low melting glass powder, 50 parts of the binder, 0.2 parts of polyethylene glycol, 0.1 parts of fluorocarbon surfactant, carboxymethylcellulose 0.3 Parts as well as silicon defoamers 0.15 parts.

[0038] Cordierite micro powder, tetraned iron fine powder, chromium oxide fine powder, cobalt oxide fine powder, manganese iron tipline fine powder and borosilicate glass powder are less than 5 μm.

[0039] The preparation method of low melting glass powder modified graphene is as follows:

[0040] S1: Take a low melting point glass powder and the solvent is mixed with a solvent to obtain a dispersion to obtain a dispersion, and a deionized water and a coupling agent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com