Chemical-looping methane partial oxidation oxygen carrier, preparation method and applications thereof

A chemical chain methane, oxygen carrier technology, applied in chemical instruments and methods, chemical recovery, inorganic chemistry, etc., can solve problems such as low syngas selectivity, achieve low wear rate, good syngas yield, and excellent oxidation The effect of restoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

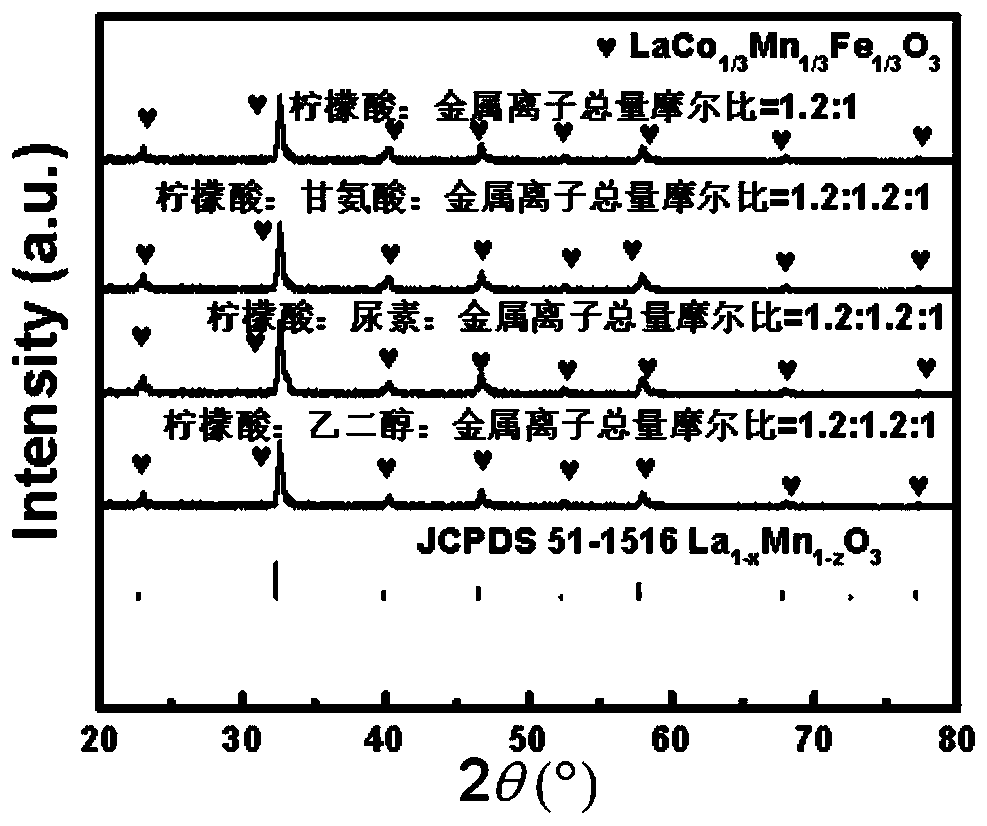

[0029] Step (1), weigh 9.7470g lanthanum nitrate hexahydrate La(NO 3 ) 3 ·nH 2 O, 2.9103g cobalt nitrate hexahydrate Co(NO 3 ) 3 ·6H 2 O, 4.04g iron nitrate nonahydrate Fe(NO 3 ) 3 9H 2 O, 3.5790 g (50 wt %) of manganese nitrate aqueous solution, 15.1301 g of citric acid, and 4.4689 g of ethylene glycol were dissolved in 40 mL of deionized water. Wherein, the molar ratio of citric acid, ethylene glycol and the total amount of metal ions in the precursor solution is 1.2:1.2:1;

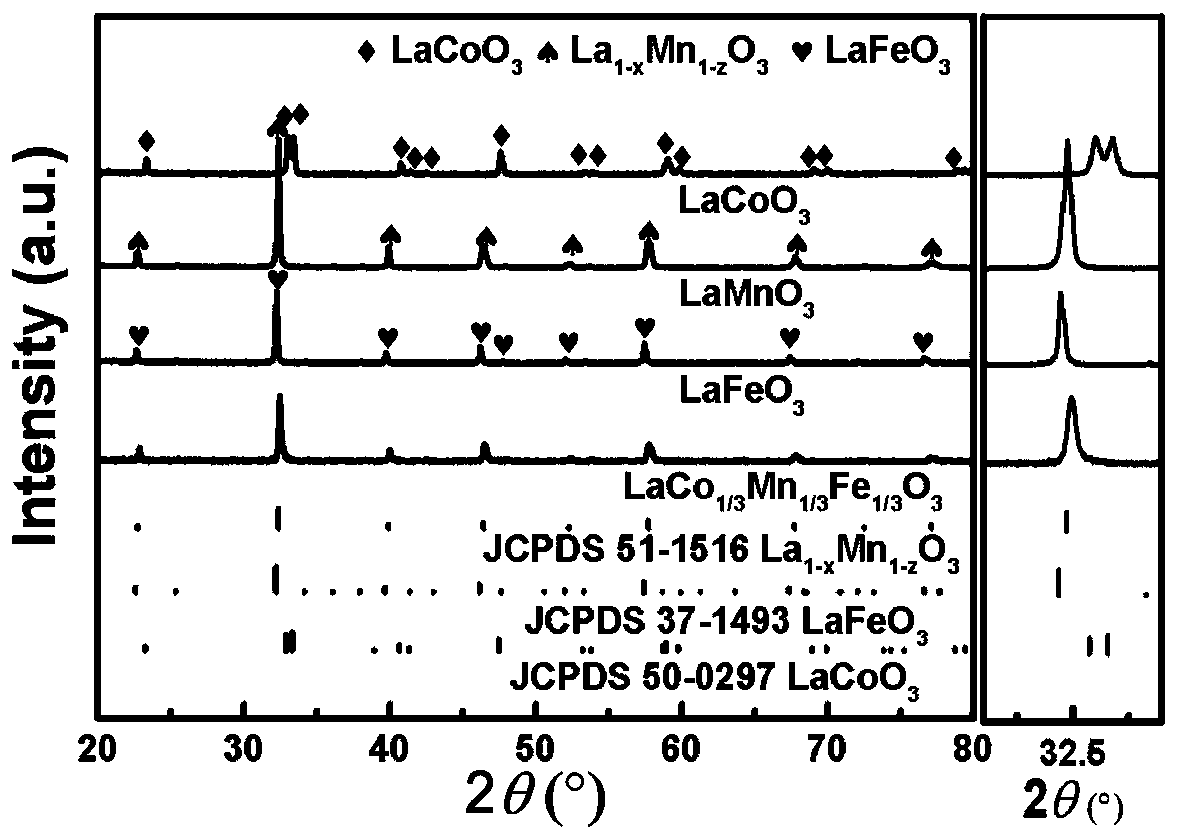

[0030] Step (2), the above solution was evaporated to dryness at 85°C under stirring conditions until it became gelatinous, and the stirring rate was 500rpm, and then placed in a 130°C constant temperature drying oven to fully dry for 12 hours, and the obtained precursor powder was placed in a 900°C muffle furnace Calcined for 4 hours to obtain a composite perovskite structure, its molecular formula is LaMn 1 / 3 Fe 1 / 3 co 1 / 3 o 3 .

[0031] The oxygen carrier was measured and crushed to take...

Embodiment 5

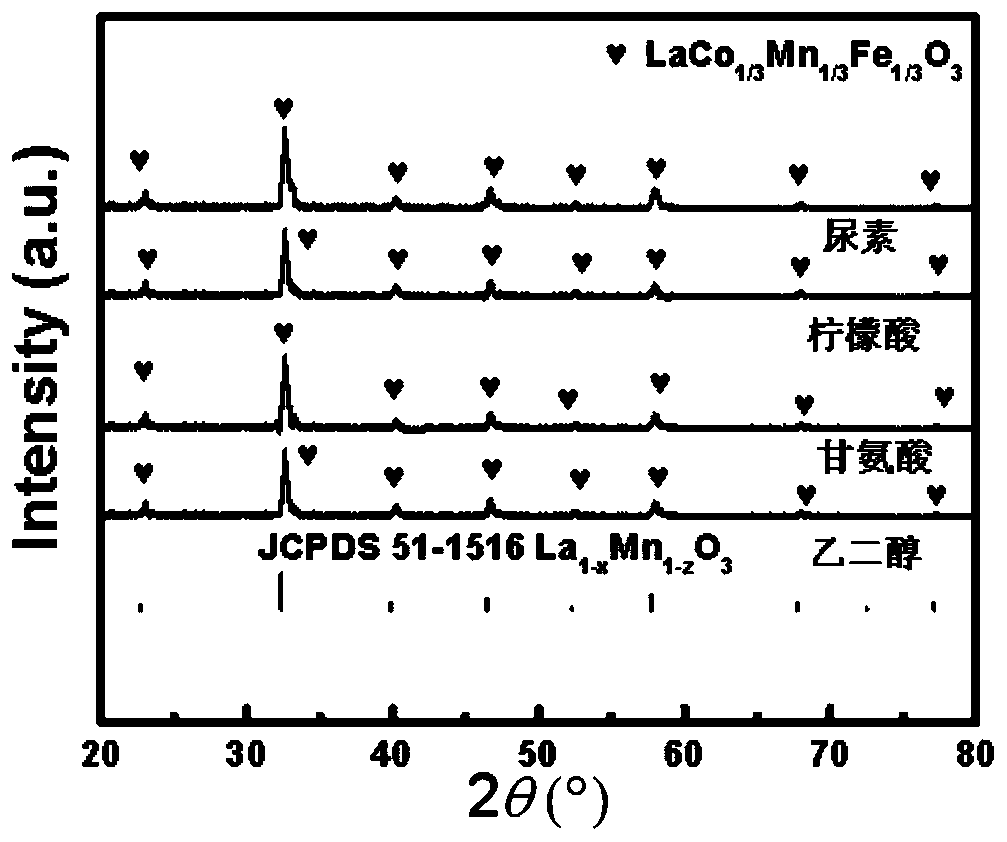

[0039] Prepared with the method of Example 1, the only difference is that the complexing agent in step (1) uses 4.4689g ethylene glycol, and the molar ratio of ethylene glycol to the total amount of metal ions in the precursor solution is 1.2:1.

Embodiment 6

[0041] Prepared with the method of Example 1, the only difference is that the complexing agent in step (1) uses 5.4051g glycine, and the molar ratio of glycine to the total amount of metal ions in the precursor solution is 1.2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com