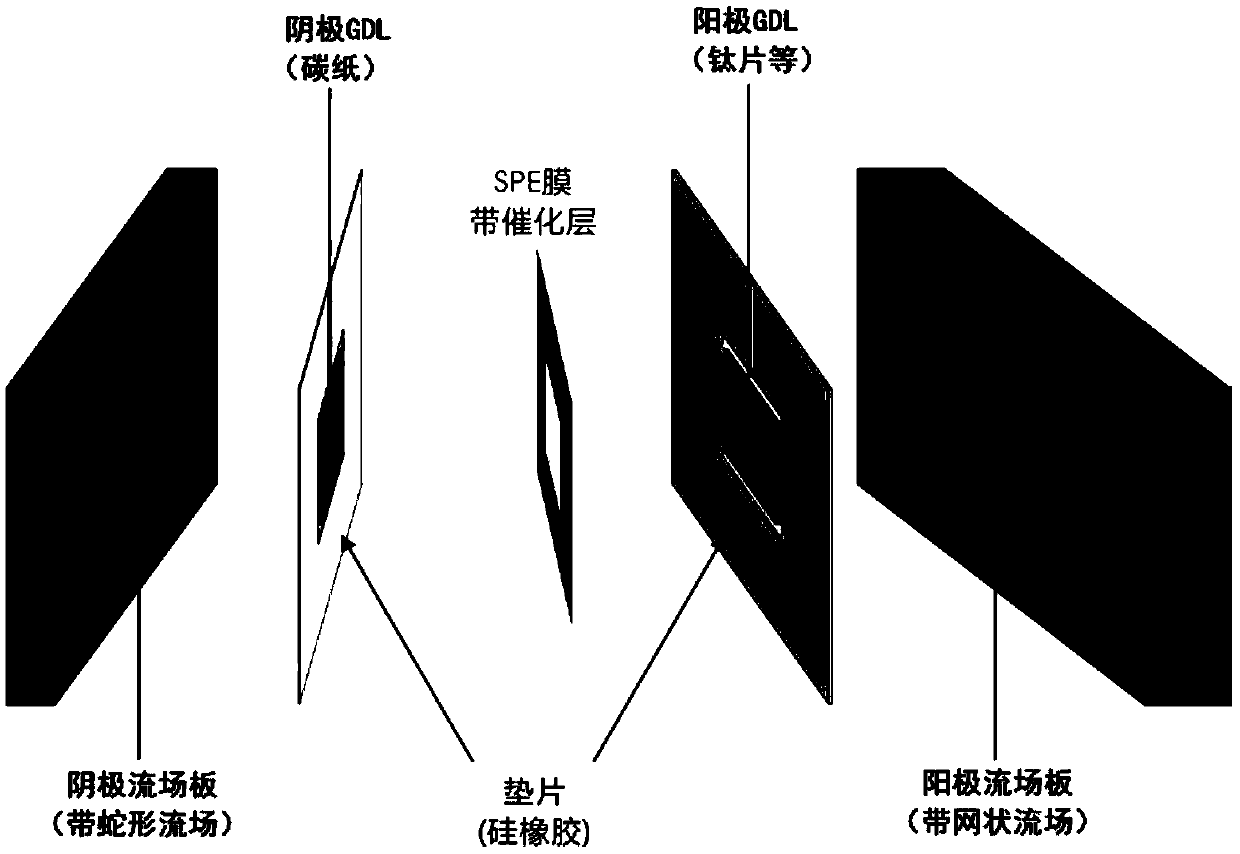

Practical carbon dioxide reduction film electrolyzer and preparation method thereof

A carbon dioxide, electrolyzer technology, applied in the direction of electrolysis components, electrolysis process, electrode shape/type, etc., can solve the problems of large internal resistance, low energy conversion rate, blockage of gas channels, etc., to achieve high practicability, broad application prospects, The effect of device area expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

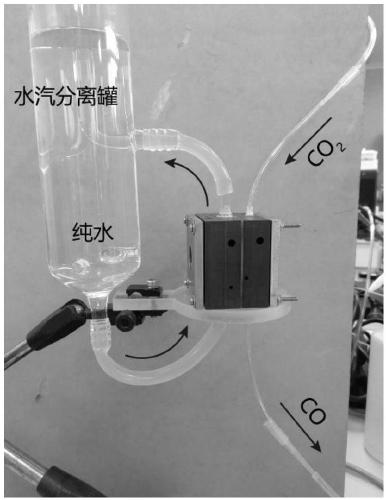

Examples

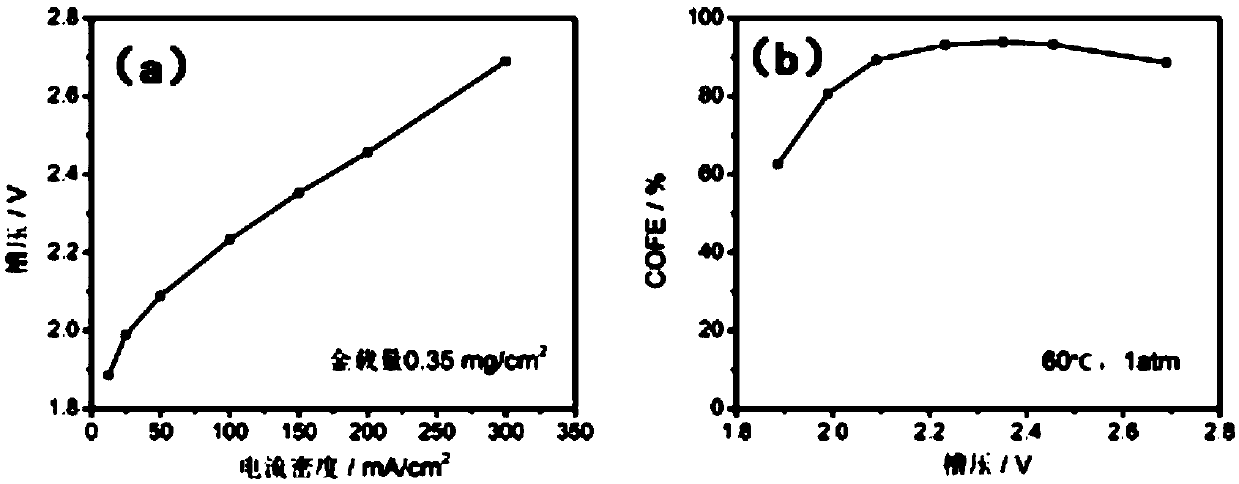

Embodiment 1

[0032] Weigh 28mg of carbon powder (Cabot Vulcan XC-72) into a 200mL three-neck flask, add 60mL of glycerin, continue to sonicate and stir until the carbon powder is evenly dispersed in glycerin, and slowly add 2ml of chloroauric acid dropwise at 50°C under stirring and reflux conditions aqueous solution (containing 0.1mmol chloroauric acid) and 2mL sodium borohydride aqueous solution (containing 2mmol NaBH 4 ), the reaction was continued for half an hour after adding, and the product was freeze-dried to obtain a powder Au / C catalyst after repeated washing with a mixed solvent of water+ethanol and centrifugation, with a gold loading of about 40% and a particle size of about 10nm.

[0033]Cut the QAPPT film into a size of 4cm*4cm for later use, and dissolve the QAPPT film material in a mixed solvent of isopropanol / DMF (volume ratio: 1:2) to obtain a light yellow initial film solution (QAPPT content 20mg / mL), Dilute to 1 mg / mL in n-propanol system as the diluted film solution, a...

Embodiment 2

[0036] Cut the QAPPT film into a size of 4cm*4cm for later use. In addition, the film material was dissolved in a mixed solvent of isopropanol / DMF (volume ratio: 1:2) to obtain a light yellow initial film solution (QAPPT content 20mg / mL). Diluted to 1mg / mL in n-propanol system as the diluted film solution, respectively weighed carbon powder (Cabot Vulcan XC-72) and cobalt phthalocyanine (CoPc) catalyst according to the mass ratio of 4:1 and mixed them initially, with a total mass of 4mg / mL ratio into the diluted film solution, fully dispersed in an ultrasonic cleaner to form a uniform ink. Use an airbrush to evenly spray the ink to the middle area (about 18mm*18mm) of the SPE film fixed on a 70°C hot plate, and weigh the IrO 2 Prepare and disperse the ink in the same proportion, spray it on the other side of the SPE film under the same conditions, and the position is consistent with that of CoPc / C to complete the electrode preparation. Soak the membrane with the catalytic la...

Embodiment 3

[0039] Cut the QAPS membrane into a size of 4cm*4cm for later use, and dissolve the membrane material in DMF to obtain a light yellow initial membrane solution (QAPS content 20mg / mL), which is diluted to 1mg / mL in n-propanol system as a diluted membrane solution According to the mass ratio of 4:1, respectively weigh the carbon powder (Cabot Vulcan XC-72) and the cobalt phthalocyanine (CoPc) catalyst and mix them initially, add the diluted membrane solution at a ratio of 4 mg / mL to the total mass, and put them in an ultrasonic cleaner Fully dispersed to form a uniform ink. Use an airbrush to evenly spray the ink to the middle area (about 18mm*18mm) of the SPE film fixed on a 70°C hot plate, and weigh the Pt-Ru / C catalyst (60%) to prepare and disperse the ink in the same proportion. Spray coating to the other side of the SPE film under the same conditions, the position is consistent with that of CoPc / C, and the electrode preparation is completed. Soak the membrane with the cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com