Surface treatment method for titanium dioxide applied to chinlon delustering agent

A titanium dioxide and surface treatment technology, applied in chemical instruments and methods, dyed low-molecular-weight organic compound treatment, dyed high-molecular-weight organic compound treatment, etc. The effect of increasing the coating rate and strong anti-pulverization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A titanium dioxide surface treatment method for nylon matting agent, comprising the following steps:

[0030] Step 1. In deionized water, add TiO 2 Powder, so that the content of titanium dioxide in the whole system is 10%-30%, stir evenly, and the added mass is TiO 2 0.5% of the steric hindrance type dispersant of the powder mass; the steric hindrance type dispersant is diluted with 2 to 5 times of its mass in deionized water and added in a downstream manner;

[0031] Before the first coating, add 0.3% of the slurry mass of ammonia water to the slurry, and use ultrasonic vibration operation with a power of 300W for 10-15min to make the TiO 2 The aqueous solution of the powder is uniform TiO 2 slurry;

[0032] Step 2, heating the above slurry to 80-85°C, 2 Add sodium silicate in the slurry, the addition amount of described sodium silicate is: SiO 2 :TiO 2 =0.02~0.05:1, stir, adjust the pH value of the slurry with dilute sulfuric acid to 7.0~8.0; when adjusting the...

Embodiment 2

[0041] Add 1000Kg of deionized water into the reaction kettle, and add 300Kg of titanium dioxide into the deionized water, wherein, titanium dioxide is anatase titanium dioxide, its mesh number is 325 mesh, take 1.5Kg of steric hindrance type dispersant, here space The steric hindrance type dispersant adopts sodium dodecylbenzenesulfonate, and the sodium dodecylbenzenesulfonate is miscible with 7.5Kg deionized water, stirred evenly, and the titanium dioxide slurry in the reaction kettle and the diluted methane The steric hindrance type dispersant is introduced into the ultrasonic reaction device at the same time. The power of the ultrasonic reaction device is 300W, and ultrasonic vibration is added while adding, and 3.9Kg of ammonia water is added to it during ultrasonication. Among them, ammonia water is an industrial-grade synthetic product, and its mass fraction is 25-28%, the ultrasonic shock time is 15min;

[0042] Transfer the above slurry to a heated stirring tank, heat...

experiment example

[0057] Embodiment 1 product test data (see table 1) and test standard;

[0058] Table 1

[0059]

[0060]

[0061] The quality requirements of titanium dioxide raw materials meet the national testing standard GB1706-2006 for titanium dioxide raw materials.

[0062] Adopt XRF (X-ray fluorescence spectrum) to carry out result analysis to the content of coated titanium dioxide product (embodiment 1), the specific data after analysis are shown in Table 2;

[0063] Table 2

[0064] Element Wt% At% OK 35.80 62.02 K 01.02 01.04 SiK 00.90 00.89 TiK 62.29 36.05

[0065] It can be seen from Table 2 that the coating amount of aluminum in titanium dioxide is 1.92%; it is at an excellent level in the national standard;

[0066] product testing:

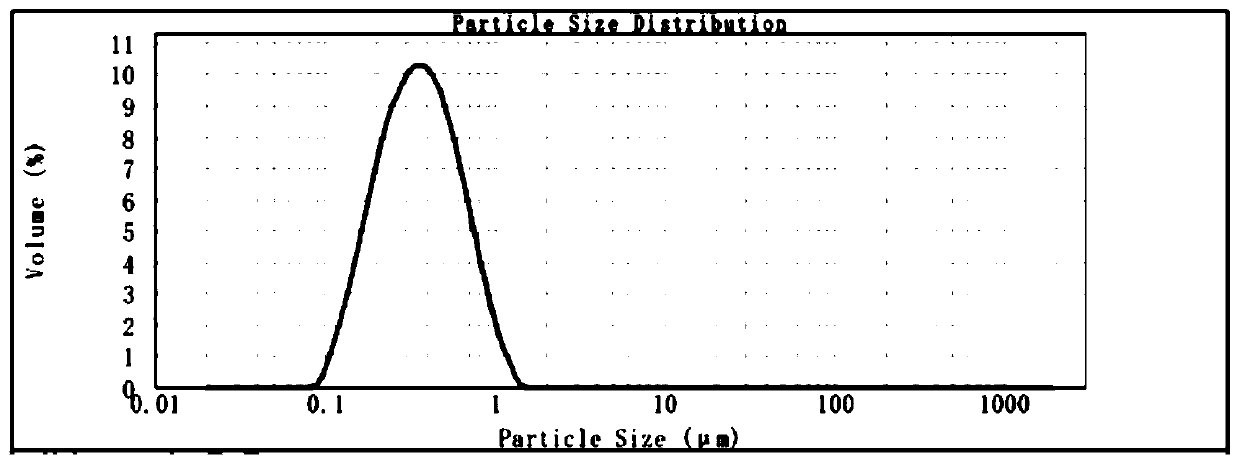

[0067] Determination of the purity of titanium dioxide according to GB1706-2006, see the attached Figure 4 ;

[0068] According to GB1717-1986 Determination of PH of Pigment Water Suspensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com