Preparation method of silicon dioxide nanorod array

A nanorod array and silicon dioxide technology, applied in the field of nanomaterials, can solve the problems of complex step-by-step operations, expensive reaction equipment, harsh reaction conditions, etc., and achieve simple and efficient preparation process, low equipment operation requirements, and no pollution in the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

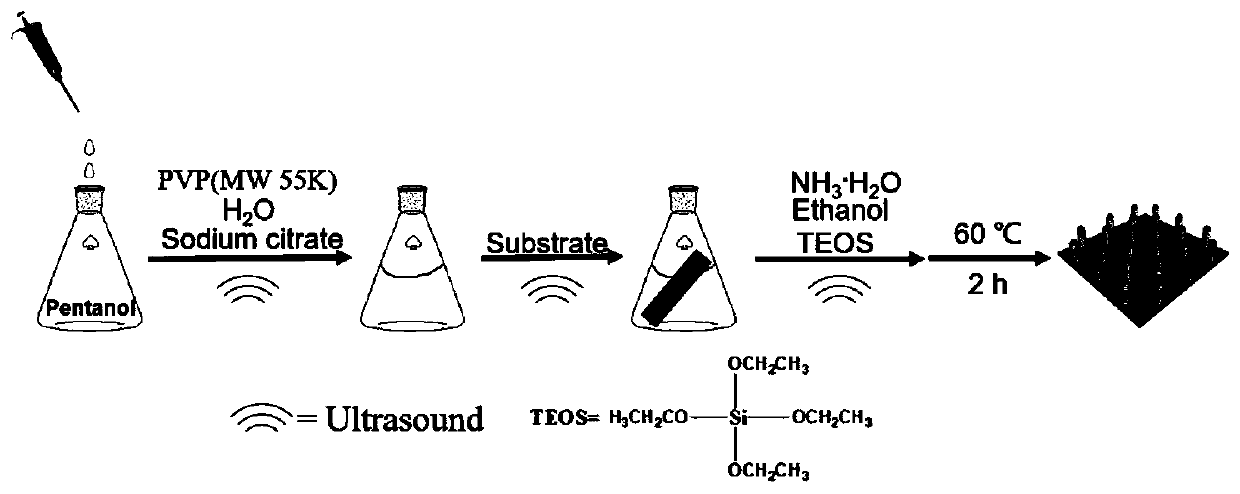

[0024] The invention provides a method for preparing a silica nanorod array, comprising: mixing an organic surfactant solution with a sodium citrate aqueous solution, then putting it into a hydrophilic substrate, adding a basic catalyst, and after ultrasonic treatment, adding The silicon source is left to stand, and the substrate is taken out to obtain a silicon dioxide nanorod array.

[0025] see figure 1 , figure 1 Schematic diagram of the preparation process of the silica nanorod array provided by the present invention.

[0026] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0027] The surfactant organic solution is mixed with the sodium citrate aqueous solution; The surfactant in the described surfactant organic solution is preferably polyvinylpyrrolidone (PVP), cetyltrimethylammonium bromide (CTAB), lauryl One or more of sodium alkyl sulfate (SDS) and polyacrylic acid (PAA), more p...

Embodiment 1

[0040] 1.1 Cleaning of the substrate: First, ultrasonically clean the ITO glass substrate with acetone, deionized water and absolute ethanol, and dry the substrate with nitrogen gas for later use.

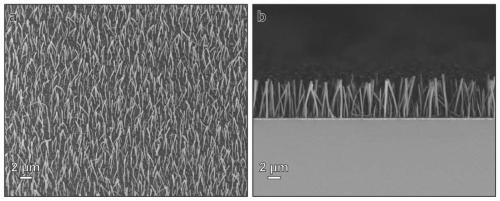

[0041] 1.2 Synthesis of silica nanorod arrays: 1 g of PVP (MW 55000) was dissolved in 10 mL of 1-pentanol by sonication, and 380 μL of aqueous sodium citrate (0.053 M) was added. Then the cleaned ITO substrate was immersed in the above solution. Then 200 μL of ammonium hydroxide solution (concentration 25%-28%) and 1 mL of ethanol were added to the reaction. Vigorous stirring was provided by ultrasonic treatment (power 60%, time 10 seconds, water temperature 20° C.) to form a stable emulsion system. The growth of silica nanorods starts with the addition of 100 μL of tetraethyl silicate (after adding tetraethyl silicate, it needs to be treated with 60% ultrasonic power for 10 seconds before standing still). The mixed solution was left to stand at 60° C. for 4 hours. Finally, the ...

Embodiment 2

[0044] 2.1 Cleaning of the substrate: Ultrasonic cleaning of the ITO glass substrate was performed with acetone, deionized water and absolute ethanol, and the substrate was blown dry with nitrogen gas for later use.

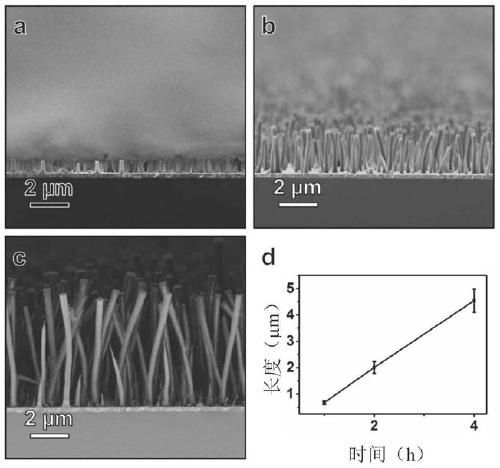

[0045] 2.2 Synthesis of silica nanorod arrays: In a typical experiment, 1 g of PVP (MW55000) was dissolved in 10 mL of 1-pentanol by sonication, and 380 μL of aqueous sodium citrate (0.053 M) was added. The cleaned substrate is then immersed in the above solution. Then 200 μL of ammonium hydroxide solution (concentration 25%) and 1 mL of ethanol were added to the reaction. Vigorous stirring was provided by ultrasonic treatment (power 99%, time 20 seconds, water temperature 30° C.) to form a stable emulsion system. The growth of silica nanorods starts with the addition of 100 μL of tetraethyl silicate (sonication first and then resting, ultrasonic power 99% for 20 seconds and then resting). The mixed solutions were left standing at 60°C for 1 hour, 2 hours and 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com