Enzyme combination for producing L-phosphinothricin, and production method of L-phosphinothricin

A production method, glufosinate-ammonium technology, is applied in the field of enzyme engineering to achieve the effects of reducing production costs, increasing product concentration and production intensity, and being extremely easy to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

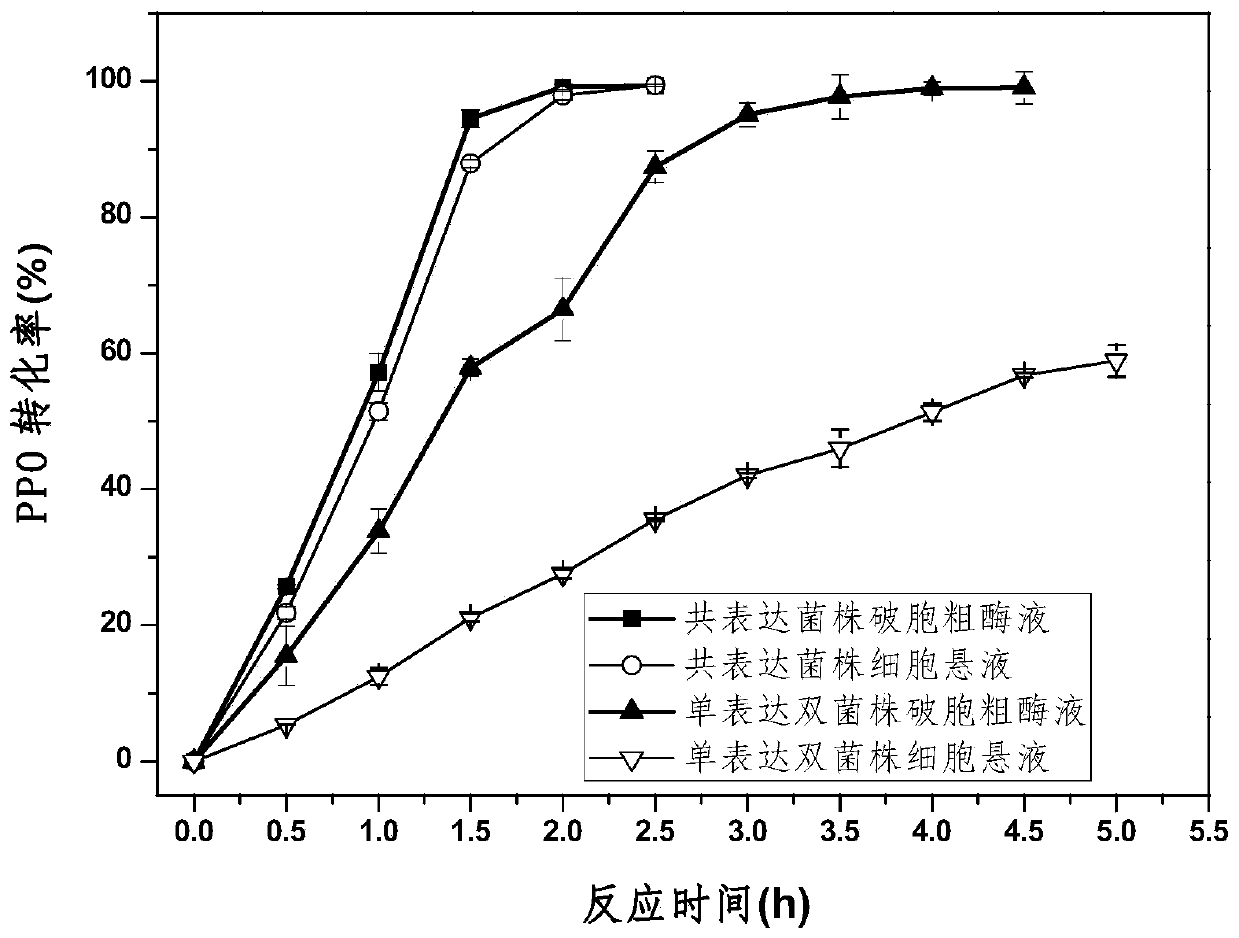

[0033] Example 1: strain construction and enzyme activity assay

[0034] 1. Strain construction

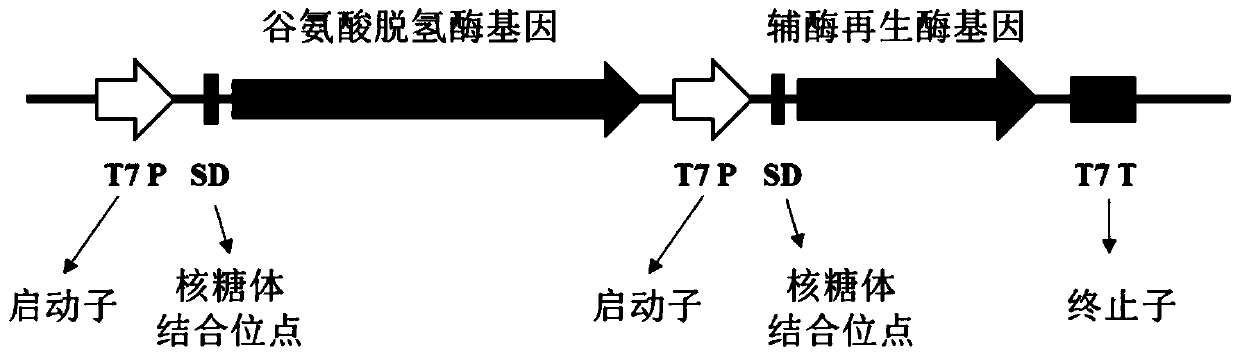

[0035] (1) Construction of genetically engineered bacteria expressing glutamate dehydrogenase

[0036] Glutamate dehydrogenase with higher catalytic activity is selected as the catalyst for preparing L-glufosinate-ammonium by the method of the present invention, and its amino acid sequence is shown in SEQ ID NO.1. The base sequence of this glutamate dehydrogenase (the glutamate dehydrogenase mutant strain (PpGluDH-T121N / L123Y) in the published patent CN 110184246A) is cloned on the relevant expression plasmid, and the expression plasmid includes: pRSFDuet, pET One of -24a(+), pET-28a(+) and pET-30a(+), the insertion sites are BamHI and HindIII; the recombinant plasmid is transformed into the expression host Escherichia coli E.coli after sequencing and verification In BL21(DE3), construct corresponding genetically engineered bacteria expressing glutamate dehydrogenase, such as E....

Embodiment 2

[0048] Embodiment 2: Adopt genetically engineered bacteria E.coli BL21(DE3) / pRSFDuet-GluDH-ADH to produce L-glufosinate-ammonium

[0049] (1) Strain activation: use an inoculation loop to take the genetically engineered bacteria E.coli BL21(DE3) / pRSFDuet-GluDH co-expressing glutamic acid dehydrogenase and alcohol dehydrogenase preserved in the -80°C glycerol tube in the strain tube - ADH strains are marked on the surface of LB-Kan-agar solid medium (plate or eggplant bottle), and the plate is inverted and placed in a constant temperature incubator at 37°C for 12 hours;

[0050] (2) Seed cultivation: re-inoculate the activated strains into 40 mL of primary seed medium, culture with shaking at 37°C for 12 hours to obtain primary seed liquid; then, transfer the primary seed liquid into 400 mL of secondary seed culture Medium, cultured with shaking at 35°C for 4 hours to obtain secondary seed liquid;

[0051] Among them, the primary seed medium is LB medium, 10g / L peptone, 5g / L y...

Embodiment 3

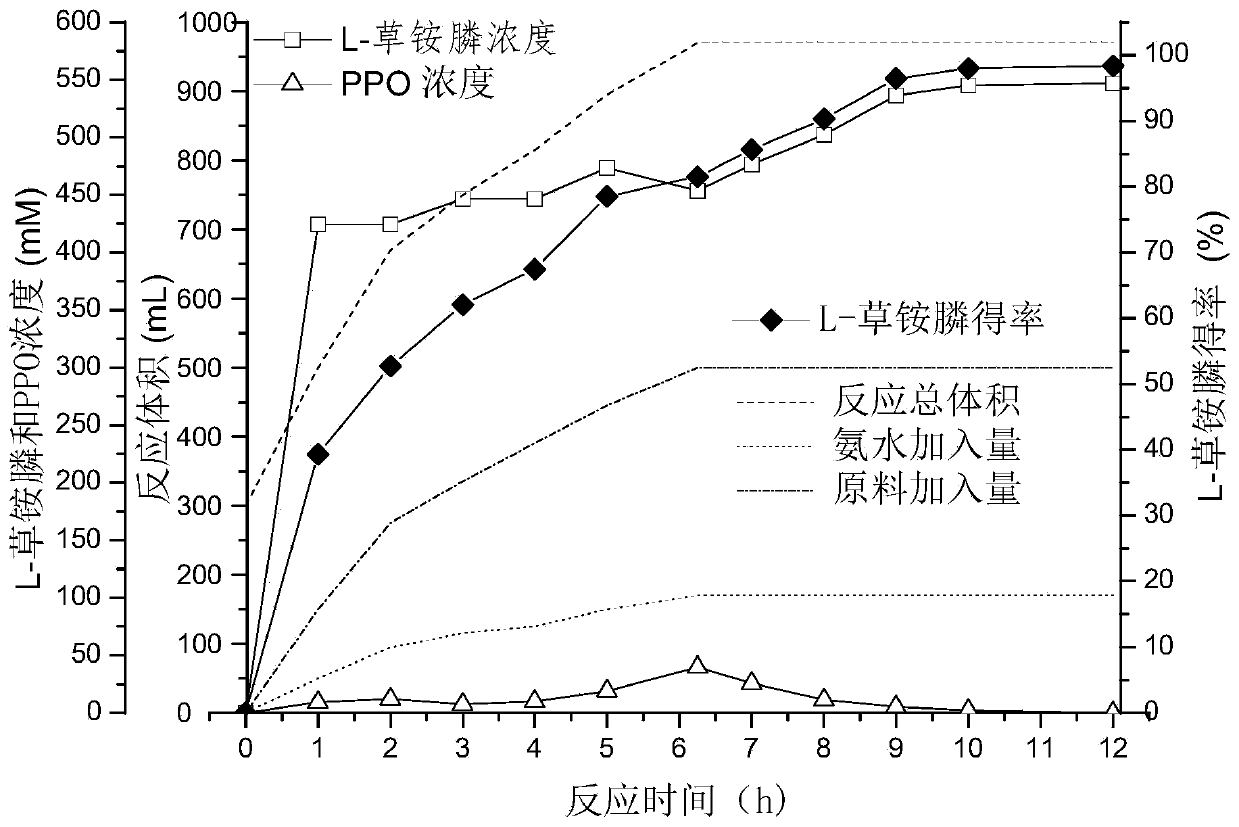

[0057] Embodiment 3: Adopt genetically engineered bacteria E.coli BL21(DE3) / pET-24a(+)-GluDH-ADH to produce L-glufosinate-ammonium

[0058] (1) The fermentation of the engineered bacteria and the acquisition of the sludge were the same as in Example 2. After fermentation, get OD 600 =296, the enzyme activity of glutamate dehydrogenase was measured as 1269U / mL in the fermentation broth, and the activity of alcohol dehydrogenase was 947U / mL.

[0059] (2) Inject 2.5L of pure water into a 10.0L reactor, add 1.5kg of bacteria slime, add water to 4.0L, start stirring, adjust the pH to 7.5 with ammonia water, and control the reaction temperature to 40°C with circulating cooling water. 2.0kg of solid PPO powder with a purity of 95% and 500mL of isopropanol were configured into 5.0L of substrate feed solution, which was continuously added to the reaction. Join NADP + Use 0.5 g to start the reaction, use ammonia water to control the pH of the reaction solution to 7.5±0.1, take sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com