Anode active material for battery and preparation method thereof

A negative electrode active material and a technology for negative electrode active materials, which are applied in the field of negative electrode active materials and their preparation, can solve the problems of insufficient compactness and insufficient stability of an aqueous homogenate system, so as to avoid the loss of active components and improve the coulombic efficiency and capacity stability. , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also proposes a preparation method comprising the negative electrode active material as described in any one of the foregoing, the method comprising:

[0059] Taking silicon oxide compound particles, doping lithium elements and non-lithium metal elements into the silicon oxide compound particles; wherein, the stoichiometric ratio of silicon and oxygen elements in the silicon oxide compound particles is 1:0.4-1:2, preferably 1 :0.6-1:1.5, more preferably 1:0.8-1:1.2.

[0060] Further, the median diameter of the silicon oxide compound particles is between 0.2-20 μm, preferably 1-15 μm, more preferably 2-10 μm. The doping temperature of non-lithium metal elements may be 400-1100°C, preferably 600-1000°C. The doping temperature of lithium element may be 400-900°C, preferably 550-850°C.

[0061] Further, the silicon oxide compound particles may be completely coated, partially coated or not coated with carbon film layer. The silicon oxide compound may...

Embodiment 1

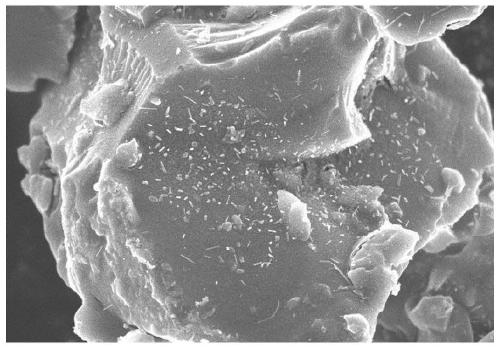

[0074] After dispersing 1000g of silicon-oxygen compound particles with a median particle size of 4 μm (the atomic ratio of silicon to oxygen is 1:1), 213.3g of tetrabutyl titanate and 25 grams of polyvinylpyrrolidone (PVP) in 3000g of deionized water, the The slurry was spray dried. Subsequently, the obtained powder was heated at 850°C for 3 hours in a nitrogen atmosphere, and then subjected to airflow crushing. According to the results of scanning electron microscopy and X-ray energy spectrum analysis (EDS), it was proved that a carbon film layer doped with titanium was obtained. silicon oxide powder. There is a small amount of titanium-containing compound residues on the surface of the particles, forming a point-like coating structure, while most of the titanium is doped into the interior of the silicon oxide compound particles (such as figure 1 ). At the same time, the results of X-ray energy spectrum analysis show that the distribution of titanium element on the silicon...

Embodiment 2

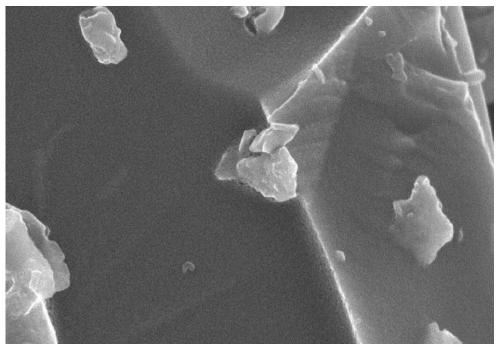

[0083] Compared with Example 1, in Example 2, silicon-oxygen compound particles are coated with a carbon film layer by chemical vapor deposition, and acetylene is used as a carbon source, and the coating reaction is carried out at 900 ° C for 3 hours, and a complete carbon film is obtained. layer of silicon oxide particles. Subsequently, 11.4g of nano-alumina was uniformly coated on the surface of 1000g of the above particles by dry coating, and kept at 800°C for 3 hours under a nitrogen atmosphere to obtain a complete carbon film doped with aluminum of silicon oxide compounds. The results of the scanning electron microscope showed that there was no aluminum-containing compound residue on the surface of the particles, indicating that the aluminum had been completely doped into the silicon-oxygen compound ( image 3 ). Next, the silicon-oxygen compound was doped with lithium metal by the same process as in Example 1 to obtain a lithium-containing silicon-oxygen compound doped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com