Perovskite quantum dot solar cell and preparation method thereof

A technology of solar cells and quantum dots, applied in the field of solar cells, can solve the problems of low short-circuit current density, inability to remove long-chain insulating ligands thoroughly, poor repeatability, etc., achieve high short-circuit current density and device performance, and improve photoelectric conversion efficiency , The effect of promoting charge transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

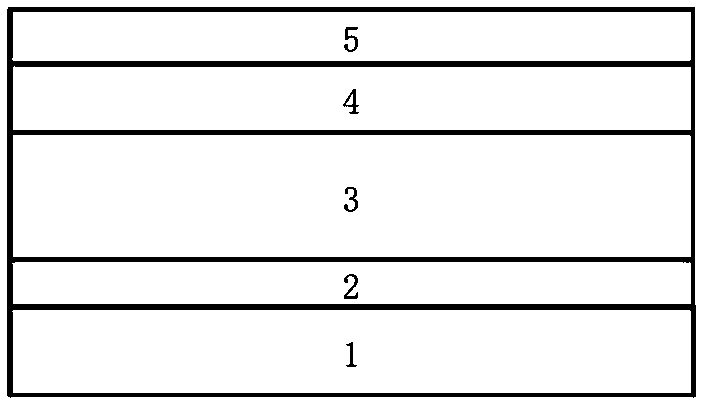

[0031] This embodiment provides a kind of perovskite quantum dot solar cell, the structure is as follows figure 1 As shown, an electron transport layer 2, a perovskite quantum dot light-absorbing layer 3, a hole transport layer 4 and a metal electrode 5 are sequentially prepared on a conductive glass substrate 1; the specific steps of preparation are as follows:

[0032] Step 1: Use detergent, deionized water, acetone and isopropanol to ultrasonically wash the FTO conductive substrate 1 in sequence; prepare a titanium oxide film with a thickness of 40 nm on the cleaned FTO by chemical bath deposition, and obtain Electron transport layer 2, and annealed at 200°C for 30 minutes;

[0033] Step 2: FTO / TiO 2 Substrate is transferred in the glove box, and the atmosphere of glove box is dry air; The CsPbI of 70mg / mL 3 Quantum dots spin-coated in n-octane solution on FTO / TiO 2 On the substrate, the spin-coating speed is 2000rpm, and then the prepared CsPbI 3 The quantum dot film i...

Embodiment 2

[0038] This embodiment provides a kind of perovskite quantum dot solar cell, the structure is as follows figure 1 As shown, the preparation of the battery includes the following steps: sequentially preparing an electron transport layer 2 , a perovskite quantum dot light-absorbing layer 3 , a hole transport layer 4 and a metal electrode 5 on a conductive glass substrate 1 . Its preparation method and concrete steps are as follows:

[0039] Step 1: Use detergent, deionized water, acetone and isopropanol to ultrasonically wash the FTO conductive substrate 1 in sequence; prepare a titanium oxide film with a thickness of 40 nm on the cleaned FTO by chemical bath deposition, and obtain Electron transport layer 2, and annealed at 200°C for 30 minutes;

[0040] Step 2: FTO / TiO 2 Substrate is transferred in the glove box, and the atmosphere of glove box is dry air; The CsPbI of 70mg / mL 3 Quantum dots spin-coated in n-octane solution on FTO / TiO 2 On the substrate, the spin-coating s...

Embodiment 3

[0045] This embodiment provides a kind of perovskite quantum dot solar cell, the structure is as follows figure 1 As shown, the preparation of the battery includes the following steps: sequentially preparing an electron transport layer 2 , a perovskite quantum dot light-absorbing layer 3 , a hole transport layer 4 and a metal electrode 5 on a conductive glass substrate 1 . Its preparation method and concrete steps are as follows:

[0046] Step 1: Use detergent, deionized water, acetone and isopropanol to ultrasonically wash the FTO conductive substrate 1 in sequence; prepare a titanium oxide film with a thickness of 40 nm on the cleaned FTO by chemical bath deposition, and obtain Electron transport layer 2, and annealed at 200°C for 30 minutes;

[0047] Step 2: FTO / TiO 2 Substrate is transferred in the glove box, and the atmosphere of glove box is dry air; The CsPbI of 70mg / mL 3 Quantum dots spin-coated in n-octane solution on FTO / TiO 2 On the substrate, the spin-coating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com