Composite bone repairing material and preparation method thereof

A composite material and bone repair technology, applied in pharmaceutical formulations, medical science, prostheses, etc., can solve problems such as easy escape, unfavorable bone proliferation, bone tissue growth, and drugs are not suitable for oral environment, so as to overcome the lack of bone mass, Promotes repair and regeneration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

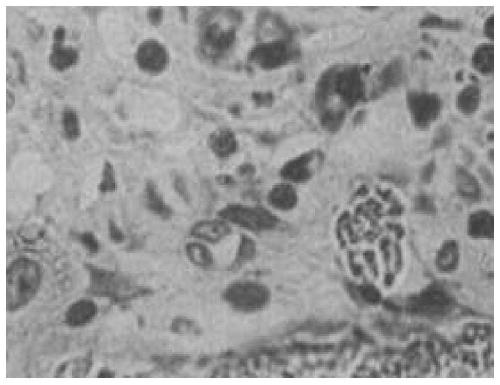

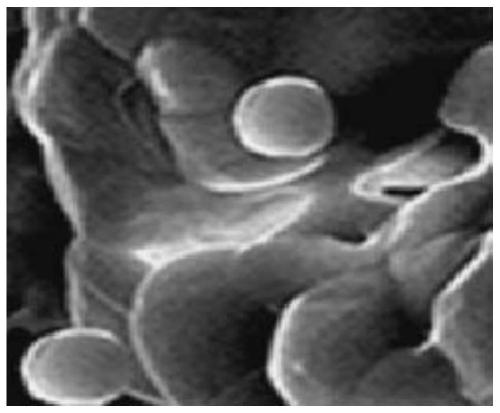

Image

Examples

preparation example 1

[0101] Preparation of porous bioactive bottom matrix

[0102] S1: 4g of hydroxyapatite powder and 2g of bioactive glass powder (55% SiO 2 -35%CaO-10%P 2 o 5 ) was added to 65ml of 1,4-dioxane solvent, and then magnetically stirred for 12 minutes to mix evenly, so that the particles were uniformly dispersed in the organic solvent to obtain a suspension of biologically active particles.

[0103] S2: 20 mL of polyε-caprolactone-dioxane solution with a mass concentration of 0.1 g / mL and 50 mL of PLGA with a mass concentration of 0.2 g / mL (the monomer ratio of polylactic acid and glycolic acid is 50:50) mixed dichloromethane solution to obtain PLGA / polyε-caprolactone mixed polymer organic solution;

[0104] S3: Add the above-mentioned bioactive particle suspension into the above-mentioned high molecular polymer organic solution, stir rapidly for preliminary mixing, and then ultrasonically disperse at room temperature for 1 min after rapid stirring and mixing, and then take an ap...

preparation example 2

[0107] Prepare the upper matrix premix slurry

[0108] S1: Dissolve 10g PLGA (molecular weight 60,000-80,000, polylactic acid and glycolic acid monomer ratio is 70:30) in 50mL dichloromethane, inject 5mL deionized water into it, and shear at 8500r / min After 1min, add it to 200mL 5% polyvinyl alcohol solution, and continue high-speed shearing for 1min; 12g; Rotary evaporation at 35-45°C to remove the organic solvent, then stand at room temperature for precipitation for 1 hour, centrifuge to separate the precipitate, wash thoroughly with deionized water, and freeze-dry to obtain PLGA microspheres;

[0109] Mix 5 g of the above-obtained PLGA microspheres and 55 g of calcium phosphate-based composite bone cement with a particle size of 10-15 μm at room temperature, and dry to obtain PLGA microspheres / calcium phosphate-based composite bone cement powder;

[0110] Among them, the calcium phosphate-based composite bone cement is composed of 80% β-tricalcium phosphate, 15% anhydrous ...

preparation example 3

[0114] Preparation of composite adhesives for bonding upper and lower end matrix scaffolds

[0115] S1: In a heated crucible, 2 g of bioactive glass particles (based on molar ratio, 55% SiO 2 -35%CaO-10%P 2 o 5 , particle size ≤ 40 μm) was added to 5 g of molten PLGA (particle size 50 μm, LA / GA = 1), stirred and mixed at 200 ° C, then cooled to room temperature, pulverized and granulated so that the particle size did not exceed 100 μm , to obtain embedding particles containing bioactive glass particles.

[0116] S2: Mix 3g of the above embedding granules, 4g of PLGA powder (LA / GA=1), 13g of n-butyl α-cyanoacrylate and 150mg of povidone-iodine (containing 12% available iodine), and stir for 3 minutes until uniform to obtain a composite adhesive.

[0117] According to GB / T 7124-2008, the bonding strength between the adhesive and the aluminum plate after curing for 15 minutes is 5.85±0.36MPa, which has excellent bonding force.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com