Novel silicon-nitrogen compound luminescent material and preparation method thereof

A silicon nitride compound and luminescent material technology, applied in the field of materials, can solve problems such as low effective conversion efficiency, narrow emission spectrum, and unstable properties, and achieve the effects of low raw material cost, good anti-attenuation characteristics, and wide excitation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Ba 1.96 GaSi 3 o 2 N 5 :0.04Eu 2+ Preparation example of luminescent material

[0036] Press Ba 1.96 GaSi 3 o 2 N 5 :0.04Eu 2+ The stoichiometric ratio weighs barium nitride, gallium nitride, silicon nitride, silicon dioxide and europium oxide and mixes them in a glove box. Put the mixed solid raw materials into a tungsten crucible and put them into a graphite furnace at 1700 degrees. Under the pressure of 1mpa, the burning reaction was carried out in a nitrogen atmosphere for 10h. After the sintered product is cooled, it is pulverized, impurity removed, dried and sieved to obtain the silicon nitride compound luminescent material.

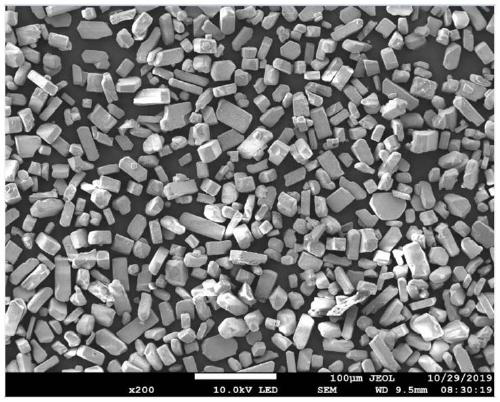

[0037] Use a fluorescence spectrometer to detect the luminous intensity and luminous spectrum of the product, use a scanning electron microscope to detect the shape of the product, and use an SSP6612 LED photochromic and electrical parameter comprehensive instrument to test the spectral characteristics of the phosphor po...

Embodiment 2

[0038] Example 2: Ba 1.96 al 0.2 Ga 0.8 Si 3 o 2 N 5 :0.04Eu 2+ Preparation example of luminescent material

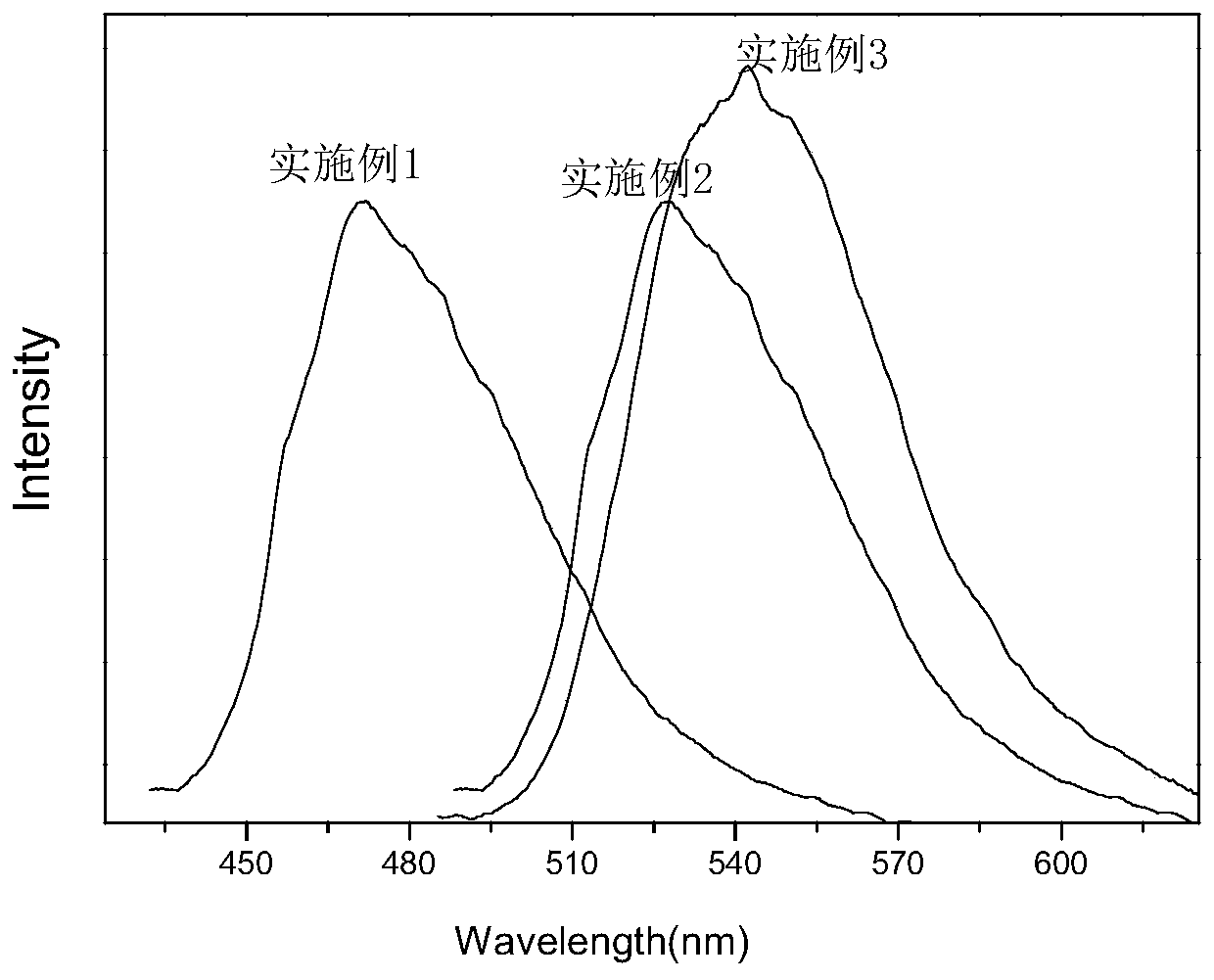

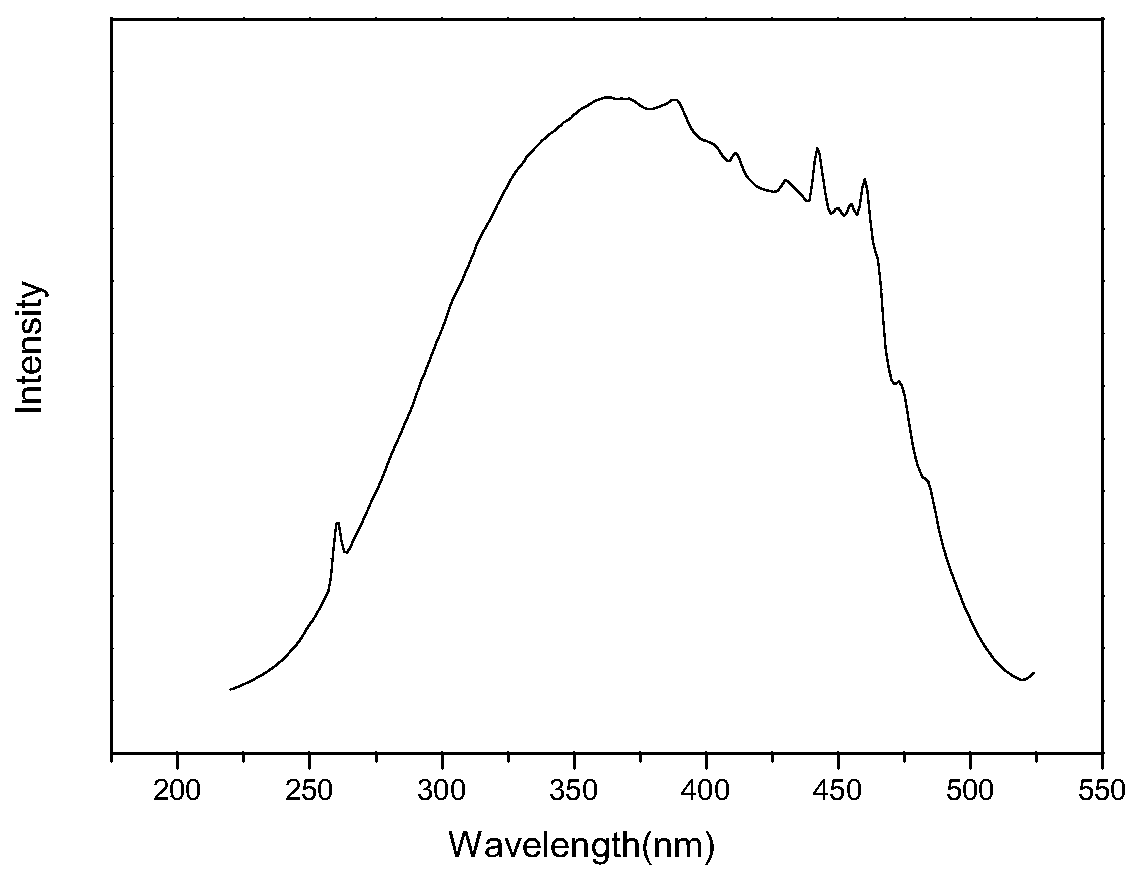

[0039] Press Ba 1.96 al 0.2 Ga 0.8 Si 3 o 2 N 5 :0.04Eu 2+ The stoichiometric ratio of barium nitride, aluminum nitride, gallium nitride, silicon nitride, silicon dioxide and europium oxide was mixed in a glove box, and the mixed solid raw materials were put into a tungsten crucible and placed in a graphite furnace , 1720 degrees, under the pressure of 1mpa, burning reaction in nitrogen atmosphere for 8h. After the sintered product is cooled, it is pulverized, impurity removed, dried and sieved to obtain the silicon nitride compound luminescent material. figure 1 The excitation spectrum of Example 2 when the emission wavelength is 520 nm and the emission spectrum when the excitation wavelength is 460 nm are shown.

Embodiment 3

[0040] Example 3: Ca 1.95 AlSi 3 o 2 N 5 :0.05Eu 2+ Preparation example of luminescent material

[0041] Press Ca 1.95 AlSi 3 o 2 N 5 :0.05Eu 2+ The stoichiometric ratio weighs calcium nitride, aluminum nitride, silicon nitride, silicon dioxide and europium oxide and mixes them in a glove box. Put the mixed solid raw materials into a tungsten crucible and put them into a graphite furnace at 1730 degrees. Under the pressure of 2mpa, the burning reaction was carried out in nitrogen atmosphere for 12h. After the sintered product is cooled, it is pulverized, impurity removed, dried and sieved to obtain the silicon nitride compound luminescent material. figure 1 The excitation spectrum of Example 3 when the emission wavelength is 550 nm and the emission spectrum when the excitation wavelength is 410 nm are shown.

[0042] Figure 4 and Figure 5 It can be seen from the comparison that the intensity of each peak is relatively high and balanced in the spectrum after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com