Preparation method for lactobacillus plantarum used for fat reducing

A technology of Lactobacillus plantarum and processed products, which is applied in the field of health food to achieve the effects of promoting fat hydrolysis, preventing absorption and accelerating metabolism in the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

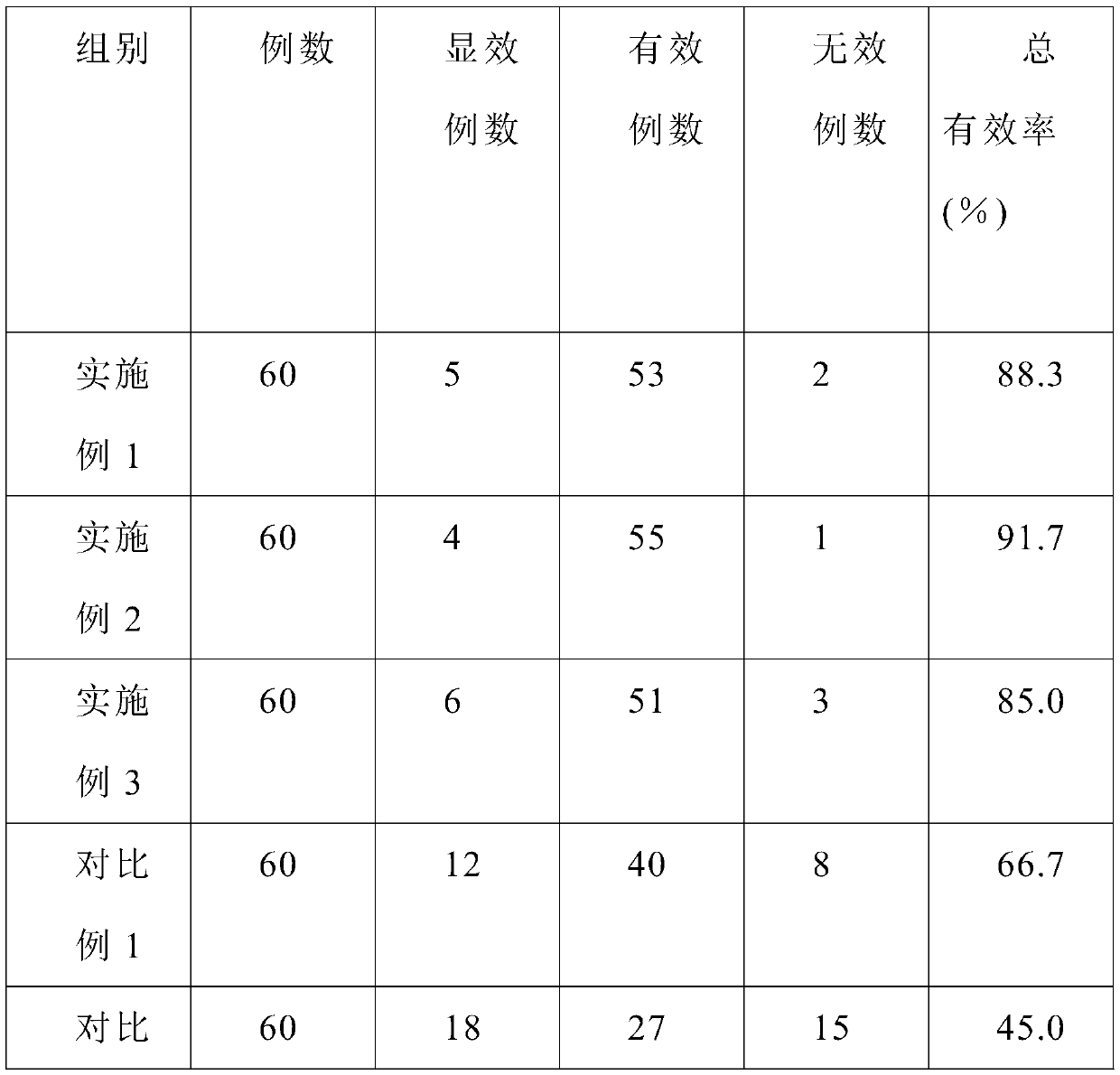

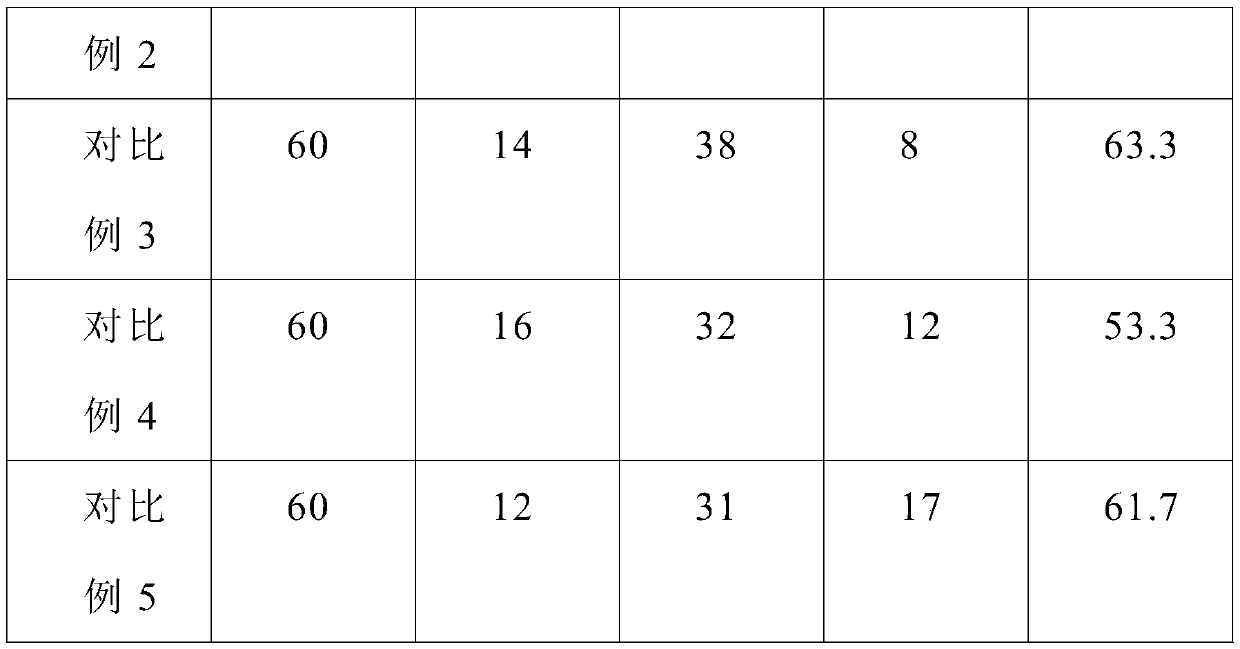

Examples

preparation example Construction

[0022] A preparation method for fat-reducing Lactobacillus plantarum, the preparation method comprising the steps of:

[0023] (1) Take the fish skin and wash it with PBS buffer solution with a pH value of 7.3 to 7.7 for 2 to 4 times, drain the water, cut it into strips with a length of 2 to 5 cm and a width of 0.8 to 1.5 cm, and put it into a freeze dryer. Freeze-dry at -10°C for 20-24 hours, take it out and crush it through an 80-mesh sieve, collect the sieved particles and add them to the impregnation solution at a mass ratio of 1:8-13, stir at 10-15°C at 300-500r / min for 10-12 hours, and then use Centrifuge at 4000-6000r / min for 6-10min, collect the centrifuge and add it to 5% acetic acid solution at a mass ratio of 1:7-11, and add enzyme with 4-8% of the centrifuge at a low temperature of 0°C Material, enzymatic hydrolysis time 44-48h, centrifuged at 5000-8000r / min for 7-12min, ultra-filtered, freeze-dried to obtain fish skin treatment;

[0024] (2) Take the fish skin tr...

Embodiment 1

[0035] A preparation method for fat-reducing Lactobacillus plantarum, the preparation method comprising the steps of:

[0036] (1) Take the fish skin and wash it twice with PBS buffer solution with a pH value of 7.3, drain the water, cut it into strips with a length of 2-5 cm and a width of 0.8-1.5 cm, put it into a freeze dryer and freeze it at -10 °C Dry for 20 hours, take out and crush through an 80-mesh sieve, collect the sieved particles and add the impregnation solution at a mass ratio of 1:8, stir at 10°C at 300r / min for 10h, then centrifuge at 4000r / min for 6min, collect the centrifuged matter at a mass ratio of 1: 7 Add acetic acid solution with a mass fraction of 5%, and at a low temperature of 0°C, add enzyme material with 4% centrifuge mass, enzymolysis time is 44h, centrifuge at 5000r / min for 7min, ultrafilter, and freeze-dry to obtain Fish skin treatment;

[0037] (2) Take the processed fish skin and add it to beef at a mass ratio of 1:6 to mix, put it into a gr...

Embodiment 2

[0048] A preparation method for fat-reducing Lactobacillus plantarum, the preparation method comprising the steps of:

[0049] (1) Take the fish skin and wash it 4 times with PBS buffer solution with a pH value of 7.7, drain the water, cut it into strips with a length of 2-5 cm and a width of 0.8-1.5 cm, put it into a freeze dryer and freeze it at -10 °C Dry for 24 hours, take out and crush through an 80-mesh sieve, collect the sieved particles and add them to the impregnation solution at a mass ratio of 1:13, stir at 15°C at 500r / min for 12h, then centrifuge at 6000r / min for 10min, collect the centrifuged matter at a mass ratio of 1: 11 Add acetic acid solution with a mass fraction of 5%, add enzyme material with 8% centrifuge mass at a low temperature of 0°C, enzymolysis time 48h, centrifuge at 8000r / min for 12min, ultrafilter, and freeze-dry to obtain Fish skin treatment;

[0050] (2) Take the fish skin treatment substance and add it to beef at a mass ratio of 1:12, put it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com