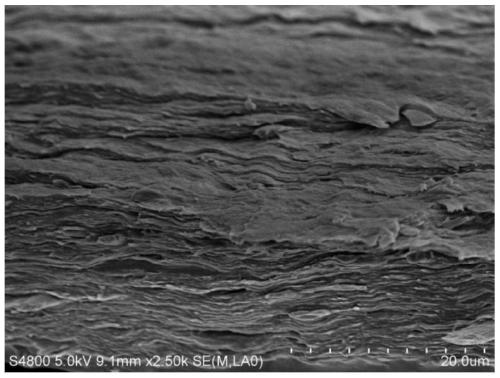

Composite cellulose nano-paper with single-sided conductivity, thermal conductivity and electromagnetic shielding function

A composite cellulose and electromagnetic shielding technology, which is applied in the direction of cellulose pulp post-treatment, cellulose pulp post-treatment modification, non-fibrous pulp addition, etc., can solve the problems of poor conductivity and reduced strength, and achieve increased strength and improved strength Low, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 10 g of tobacco rods were mechanically crushed to 20 mesh, and added to a formic acid solution with a concentration of 80 wt%. The content of lignin in the tobacco rod is 31%, and the weight ratio of the added tobacco rod to the formic acid solution is 1:50. After reacting at a temperature of 90°C and a stirring speed of 800rpm for 8 hours, the hydrolysis residue was washed until neutral; then dimethyl sulfoxide was added to the solid for replacement to obtain a suspension of cellulose nanofibrils; After the homogenization treatment, the content of nanofibers in the cellulose suspension is 0.5wt%, the pressure is 100 MPa, and the homogenization times are 10 times; after the treatment, a uniform dispersion of cellulose nanofibrils is obtained. The content of lignin in the treated cellulose nanofibrils is 17%; at the same time, the hydrolyzed product is subjected to solid-liquid separation, and the separated liquid is subjected to vacuum distillation to recover formic...

Embodiment 2

[0037] (1) Mechanically pulverize 10 g of unbleached softwood pulp to 20 mesh, and add it into a formic acid solution with a concentration of 65 wt%. The content of lignin in the unbleached softwood pulp is 13%, and the weight ratio of added wood pulp to formic acid solution is 1:25. After reacting for 9 hours at a temperature of 100°C and a stirring speed of 900rpm, the hydrolysis residue was washed until neutral; then dimethylacetamide was added to the solid for replacement to obtain a suspension of cellulose nanofibrils; After the homogenization treatment, the content of nanofibers in the cellulose suspension is 1 wt%, the pressure is 110 MPa, and the homogenization times are 12 times; after the treatment, a uniform dispersion of cellulose nanofibrils is obtained. The content of lignin in the cellulose nanofibrils after treatment is 8.2%. At the same time, the hydrolyzate is subjected to solid-liquid separation, and the separated liquid is subjected to vacuum distillation t...

Embodiment 3

[0042] (1) Mechanically pulverize 10 g of corn bracts to 20 meshes, and add them into a formic acid solution with a concentration of 85 wt%. The content of lignin in the corn bracts is 12%, and the weight ratio of the added corn bracts to the formic acid solution is 1:100. After reacting for 7 hours at a temperature of 91°C and a stirring speed of 300rpm, the hydrolysis residue was washed until neutral; then dimethylacetamide was added to the solid for replacement to obtain a suspension of cellulose nanofibrils; After the homogenization treatment, the content of nanofibers in the cellulose suspension is 0.6wt%, the pressure is 120MPa, and the number of homogenization is 5 times; after the treatment, a uniform dispersion of cellulose nanofibrils is obtained. The content of lignin in the cellulose nanofibrils after treatment is 9.5%. At the same time, the hydrolyzate is subjected to solid-liquid separation, and the separated liquid is subjected to vacuum distillation to recover ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com