Method for detecting cyanide content in electroformed gold product by headspace gas chromatography

A headspace gas chromatography and cyanide technology, applied to the determination of cyanide content in electroformed gold products, using headspace gas chromatography to detect cyanide content in electroformed gold products, can solve the problem of cyanide Problems such as high risk, disrupting market order, and lack of cyanide detection methods have achieved the effect of increasing the detection amount and promoting healthy long-term development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0061] Influence of different dissolving reagents of example 1 on the detection of cyanide content in electroformed gold products

[0062] Select 6 kinds of electroforming process gold product samples, two of which are cyanide-free electroforming process (No. 1#, 2#), and 4 kinds are cyanide electroforming process (3#, 4#, 5#, 6#) . Analytical pure solution of hydrogen peroxide refers to commercially available 30wt% hydrogen peroxide solution. Due to the standard electrode potential of the gold element is 1.498V, It is 1.692V, which shows that the ion oxidation of gold is extremely strong, on the contrary, it shows that gold atoms are extremely weak and difficult to be oxidized; therefore, this method needs to first select a suitable reagent to reduce its redox potential and improve the reducibility of gold atoms. Chlorine The presence and increased concentration of ions can effectively reduce their oxidation, such as: The standard electrode potential is 1.002V, and the...

example 2

[0067] Influence of Example 2 Different Extraction Reagents on the Detection of Cyanide Content in Electroformed Gold Products

[0068] Adopt six samples selected in Example 1 to carry out the cyanide separation and extraction experiment, take by weighing 0.2g sample pulverization, dissolve sample (1-SJ-8#) successively according to step one optimal condition, obtain sample aqueous solution.

[0069] Transfer the sample aqueous solution to a round bottom flask, add 6 different extraction reagents, 3-SJ-1#: 15mL hydrochloric acid; 3-SJ-2#: 15mL phosphoric acid; 3-SJ-3#: 15g trichloroacetic acid; 3-SJ-4#: 15g tartaric acid; 3-SJ-5#: 15mL hydrochloric acid, 15g disodium edetate; 3-SJ-6#: 2g trichloroacetic acid, 15g disodium edetate; 3-SJ-7#: tartaric acid 8g, edetate disodium 15g; 3-SJ-8#: trichloroacetic acid 2g, tartaric acid 8g, edetate disodium 15g, reflux at 100°C respectively , under airtight conditions, distilled fraction is absorbed with 40mL 30g / L sodium hydroxide aque...

example 3

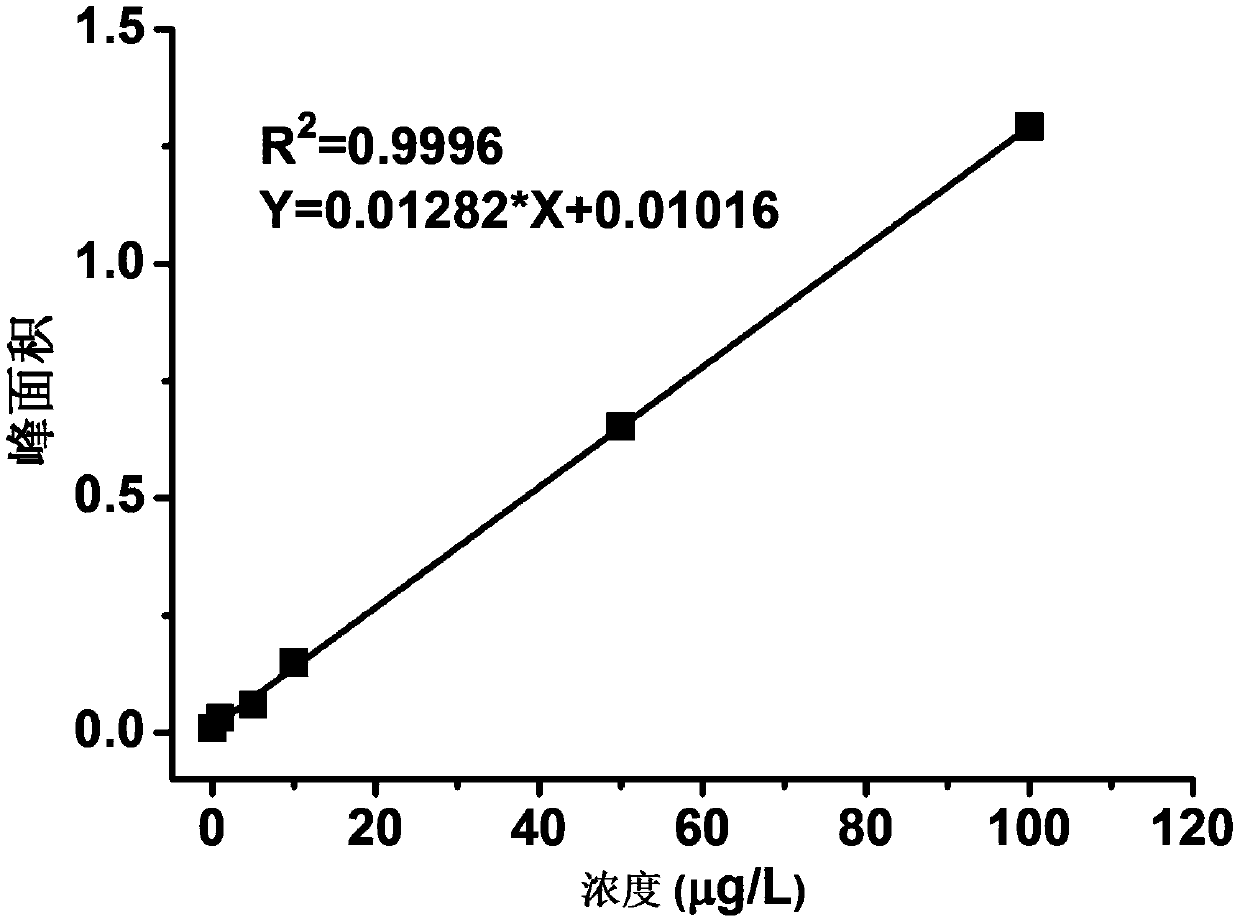

[0074] Adopt six samples selected in Example 1 to carry out research experiment, take 0.2g sample and pulverize, dissolve sample successively according to step 1 and step 2 optimal conditions (1-SJ-8# and 2-SJ-8#), separate Cyanide was extracted to obtain a cyanide absorption solution, the volume of the separated cyanide absorption solution was adjusted to 50 mL, and 10 mL was added to different headspace chromatography headspace solutions.

[0075] To investigate the influence of different headspace gas chromatography headspace solutions on the detection of cyanide content in electroformed gold products:

[0076] Different headspace chromatographic headspace solutions are as follows, 3-SHY-1#: 40 μL of analytically pure phosphoric acid; 3-SHY-2#: 0.1 mL of 20 g / L chloramine T solution; 3-SHY-3#: 20μL phosphoric acid analytical grade and 0.1mL 20g / L chloramine T solution; 3-SHY-4#: 40μL phosphoric acid analytical grade and 0.05mL 20g / L chloramine T solution; 3-SHY-5#: 80μL phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com