Nitrogen-phosphorus-potassium full-slow-release fertilizer, preparation method and application method thereof

A manufacturing method and technology of nitrogen, phosphorus and potassium, applied in the field of fertilizers, can solve the problems of soil degradation, difficult to degrade, lack of magnesium, etc., and achieve the effects of adjusting soil acid-base balance, realizing nutrient release period, and improving soil properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

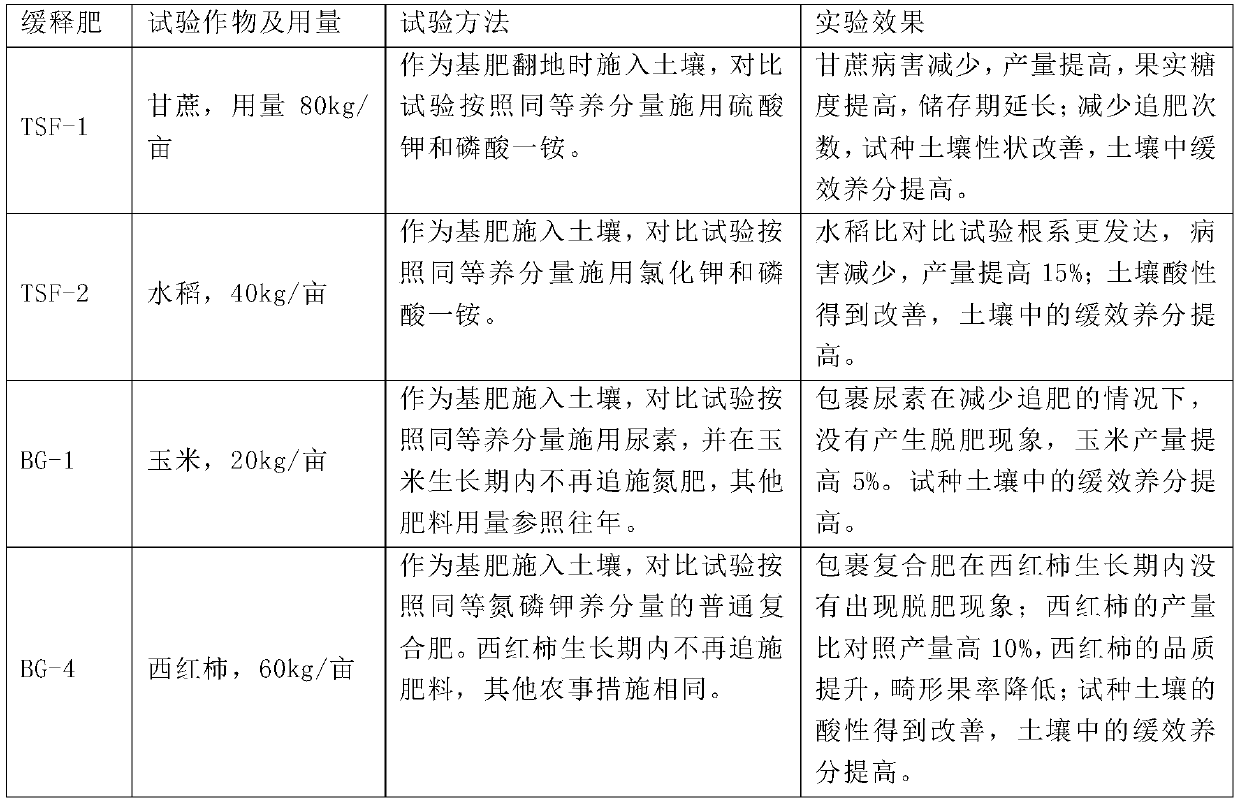

Examples

Embodiment 1

[0138] The raw material component analysis table that table 3 embodiment 1 uses

[0139] name SiO 2

Al 2 o 3

Fe 2 o 3

MgO CaO Na 2 o

K 2 o

Potassium feldspar powder 61.30 16.99 2.84 0.5 0.5 1.32 13.37 Dolomite powder 0.20 0.07 0.21 21.03 31.08 0.05 0.01

[0140] Note: The data in the table are all mass percentages.

[0141] Take by weighing 1000g potassium feldspar powder, 450g dolomite powder and 50g salt of wormwood, and add 300g 48% potassium hydroxide solution again, stir the raw meal prepared, the R of this raw meal x O / SiO 2 The ratio is 0.95, and the uniformly mixed raw material is placed in a box-type electric furnace at 1150 ° C for 30 minutes of heat preservation and calcination, and then ground after cooling to obtain 1370 g of sintered clinker powder.

[0142] Get 500g of sintered clinker powder and place it in the mixer, and add and dissolve 26g of ammonium dihydrogen phosphate (NH 4 h ...

Embodiment 2

[0154] The raw material component analysis that table 6 embodiment 2 uses

[0155] name SiO 2

Al 2 o 3

Fe 2 o 3

MgO CaO Na 2 o

K 2 o

nepheline syenite 54.68 20.26 4.78 0.8 1.29 0.45 13.19

[0156] Note: The data in the table are all mass percentages.

[0157] Weigh 1000g nepheline syenite powder (in nepheline syenite, usually KAlSi 3 o 8 Content≥60% or K 2 O content ≥ 10%)), 400g calcium carbonate powder and 520g potassium carbonate, the prepared raw meal is stirred evenly, the R of this raw meal x O / SiO 2 The ratio is 1.31. The evenly stirred raw material is placed in a box-type electric furnace and calcined at 900°C for 60 minutes. After the material is naturally cooled, it is ground to obtain 1540g of clinker powder.

[0158] Get 500g of sintered clinker powder and place it in the mixer, and add and dissolve 58g of ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and 60g magnesium sulfate (MgSO 4 ) of th...

Embodiment 3

[0166] Take by weighing 1000g potassium phonolite powder (with potassium feldspar as the main mineral component, usually KAlSi 3 o 8 Content≥60% or K 2 O content ≥ 10%), 72g quicklime, 98g magnesite powder (as MgCO 3 is the main mineral component), 160g iron ore powder, 165g potassium carbonate and 400g 48% potassium hydroxide solution, stir the prepared raw meal evenly, the R of the raw meal x O / SiO 2The ratio is 1.03, and the evenly stirred raw material is placed in a box-type electric furnace and calcined at 1000 ° C for 120 minutes. After the material is cooled, it is ground to obtain 1500 g of clinker.

[0167] Get 500g of sintered clinker powder and place it in the mixer, and add and dissolve 350g of ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and 360g magnesium sulfate (MgSO 4 ) of aqueous solution 1200g, after stirring evenly, use a disc granulator to make granules, and the granulated materials are dried in an oven to become nitrogen, phosphorus and potassium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com