Copper-plated graphite film reinforced copper-based laminated block composite material and preparation method thereof

A technology of copper-coated graphite and composite materials, which is applied in the fields of integrated circuits, metal matrix composites, thermal management, and electronic packaging materials. Interface bonding and other problems, to achieve the effect of good interface bonding state, convenient adjustment of shape and size, and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

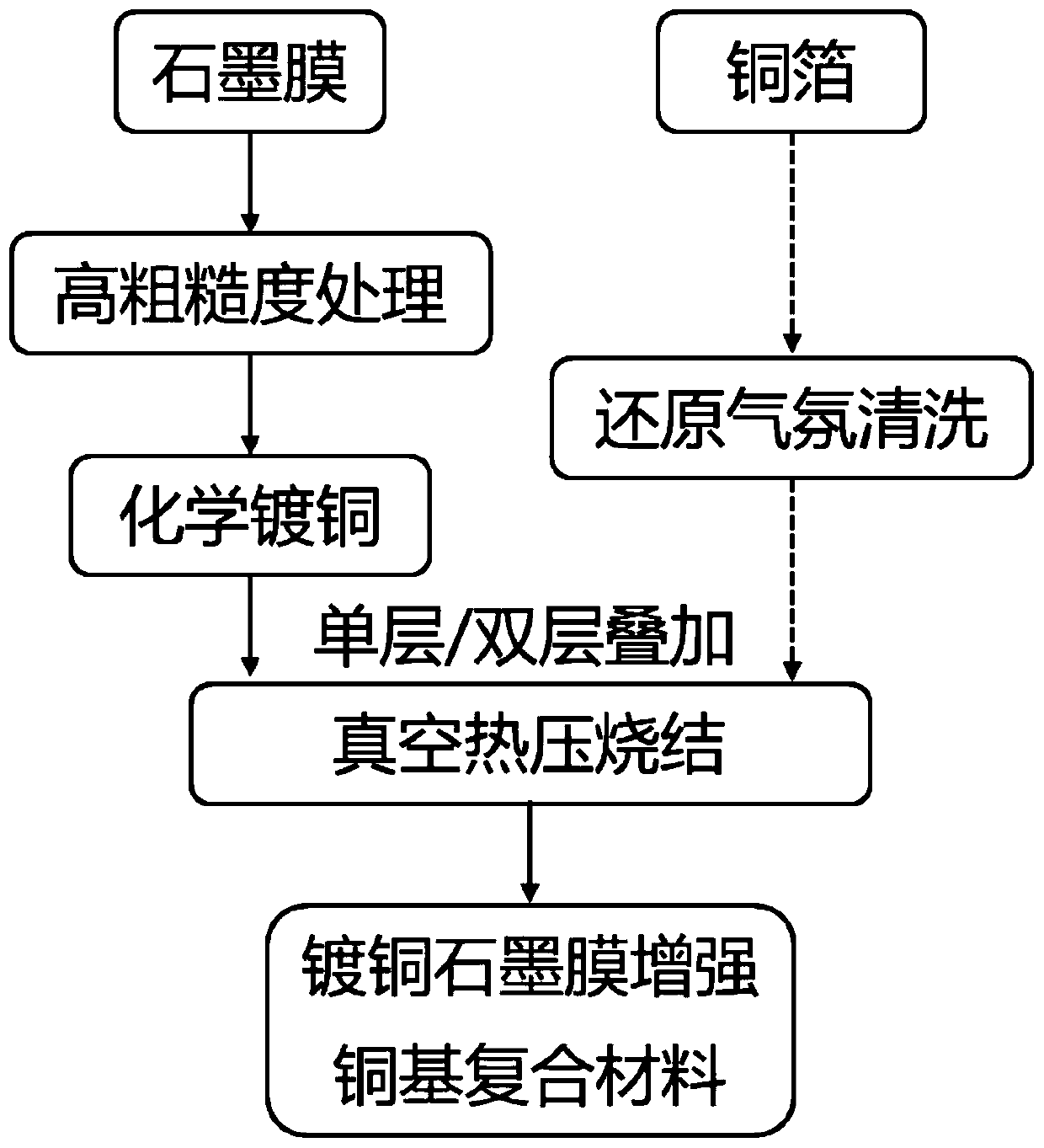

[0034]This example relates to a kind of preparation method of copper-plated graphite film reinforced copper-based composite material, refer to figure 1 shown, including the following steps:

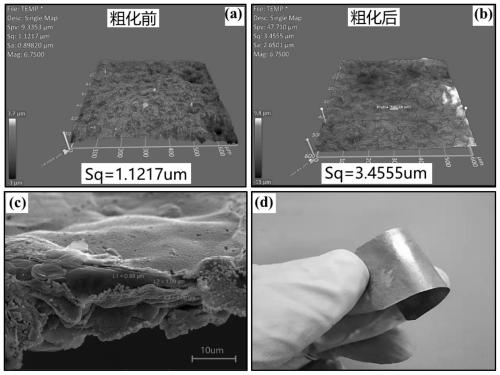

[0035] Graphite film pretreatment: cut the graphite film with a thickness of 25 μm for use, wash it several times with acetone, dry it, put it in a crucible and place it in a muffle furnace, and heat it at 400°C for 30 minutes to remove organic substances, and cool to room temperature , soaked in an ethanol solution of 10% hydrochloric acid by mass fraction, and ultrasonically treated for 10 minutes, and finally cleaned with deionized water and dried for use. figure 2 (a)(b) shows that the surface roughness of the graphite film after treatment is increased by nearly 3 times, and the height difference exceeds 20 μm. The roughening effect is obvious, and it is used to provide more attachment points for copper ions.

[0036] Graphite film sensitization treatment: put the treated graphite f...

Embodiment 2

[0044] This example relates to a kind of preparation method of copper-plated graphite film reinforced copper-based composite material, refer to figure 1 shown, including the following steps:

[0045] Graphite film pretreatment: Cut the graphite film with a thickness of 17 μm for use, wash it several times with acetone, dry it, put it in a crucible and place it in a muffle furnace, and heat it at 400°C for 30 minutes to remove organic substances. After cooling to room temperature, Soak with ethanol solution of 10% hydrochloric acid by mass fraction, and ultrasonic treatment for 10min, and finally rinse with deionized water and dry for use. basically as figure 2 It is shown that the roughness of the graphite film surface after treatment is increased by nearly 3 times, and the height difference is more than 20 μm. The roughening effect is obvious, which is used to provide more attachment points of copper ions.

[0046] Graphite film sensitization treatment: put the treated gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com