A kind of environment-friendly antibacterial plastic film and preparation method thereof

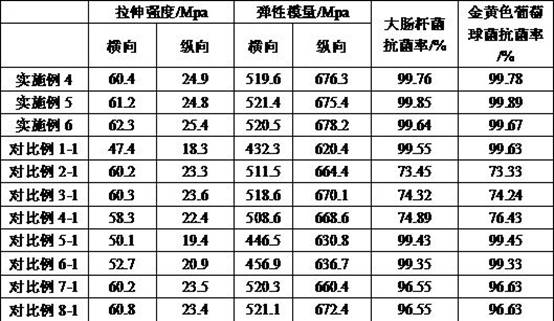

A plastic film and environmental protection technology, applied in the field of environmental protection antibacterial plastic film and its preparation, can solve the problems of low tensile strength, low antibacterial performance, poor binding force, etc., and achieve obvious strength increase, good sterilization effect, and improved strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation method of modified copper oxide-titanium dioxide-zinc oxide composite nanofibers, the concrete steps are as follows:

[0033]Take 0.5mol of zinc chloride, add 2L of a mixed solvent of ethylene glycol and water (volume ratio of ethylene glycol and water is 1:3), add 0.5mol of sodium hydroxide, ultrasonically mix for 10min, and then add 0.8mol of titanium dioxide and 0.1mol of nitric acid Copper, then add 0.4mol of polyvinylpyrrolidone, continue to stir for 10min, and then transfer to a high-pressure hydrothermal reaction kettle lined with polytetrafluoroethylene. After reaching room temperature, take out, filter, wash and dry to obtain copper oxide-titanium dioxide-zinc oxide composite nanofibers; add propanol to the copper oxide-titanium dioxide-zinc oxide composite nanofibers, stir, and then add a titanate coupling agent, Heating to 50-60°C, stirring the reaction uniformly for 1 h, removing the solvent after stopping the reaction, washing ...

Embodiment 2

[0034] Embodiment 2: the preparation method of modified copper oxide-titanium dioxide-zinc oxide composite nanofibers, the concrete steps are as follows:

[0035] Take 0.45mol zinc chloride, add 2L of a mixed solvent of ethylene glycol and water (volume ratio of ethylene glycol and water is 1:3), add 0.5mol sodium hydroxide, carry out ultrasonic mixing for 10min, then add 0.7mol titanium dioxide and 0.1mol nitric acid copper, then add 0.5mol of polyvinylpyrrolidone, continue to stir for 12min, and then transfer to a high-pressure hydrothermal reaction kettle lined with polytetrafluoroethylene. After cooling to room temperature, take it out, filter, wash and dry to obtain copper oxide-titanium dioxide-zinc oxide composite nanofibers; add propanol to the copper oxide-titanium dioxide-zinc oxide composite nanofibers, stir, and then add a titanate coupling agent , heated to 50-60 ℃, uniformly stirred for 3 hours, and the solvent was removed after the reaction was stopped, washed, ...

Embodiment 3

[0036] Embodiment 3: the preparation method of modified copper oxide-titanium dioxide-zinc oxide composite nanofibers, the concrete steps are as follows:

[0037] Take 0.4mol of zinc chloride and add 2L of a mixed solvent of ethylene glycol and water (the volume ratio of ethylene glycol and water is 1:3), add 0.5mol of sodium hydroxide, carry out ultrasonic mixing for 10min, and then add 0.6mol of titanium dioxide and 0.1mol of nitric acid Copper, then add 0.6mol of polyvinylpyrrolidone, continue to stir for 12min, and then transfer to a high-pressure hydrothermal reaction kettle lined with polytetrafluoroethylene. After cooling to room temperature, take it out, filter, wash and dry to obtain copper oxide-titanium dioxide-zinc oxide composite nanofibers; add propanol to the copper oxide-titanium dioxide-zinc oxide composite nanofibers, stir, and then add a titanate coupling agent , heated to 50-60 ℃, uniformly stirred and reacted for 5h, after the reaction was stopped, the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com