Perovskite photoelectric detector based on hole transport layer and preparation method thereof

A technology of hole transport layer and photodetector, which is applied in photovoltaic power generation, electric solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of Spiro-OMeTAD low mobility, short life, poor device stability, etc., and achieve high Air stability and isolation of water and oxygen, improved stability and life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

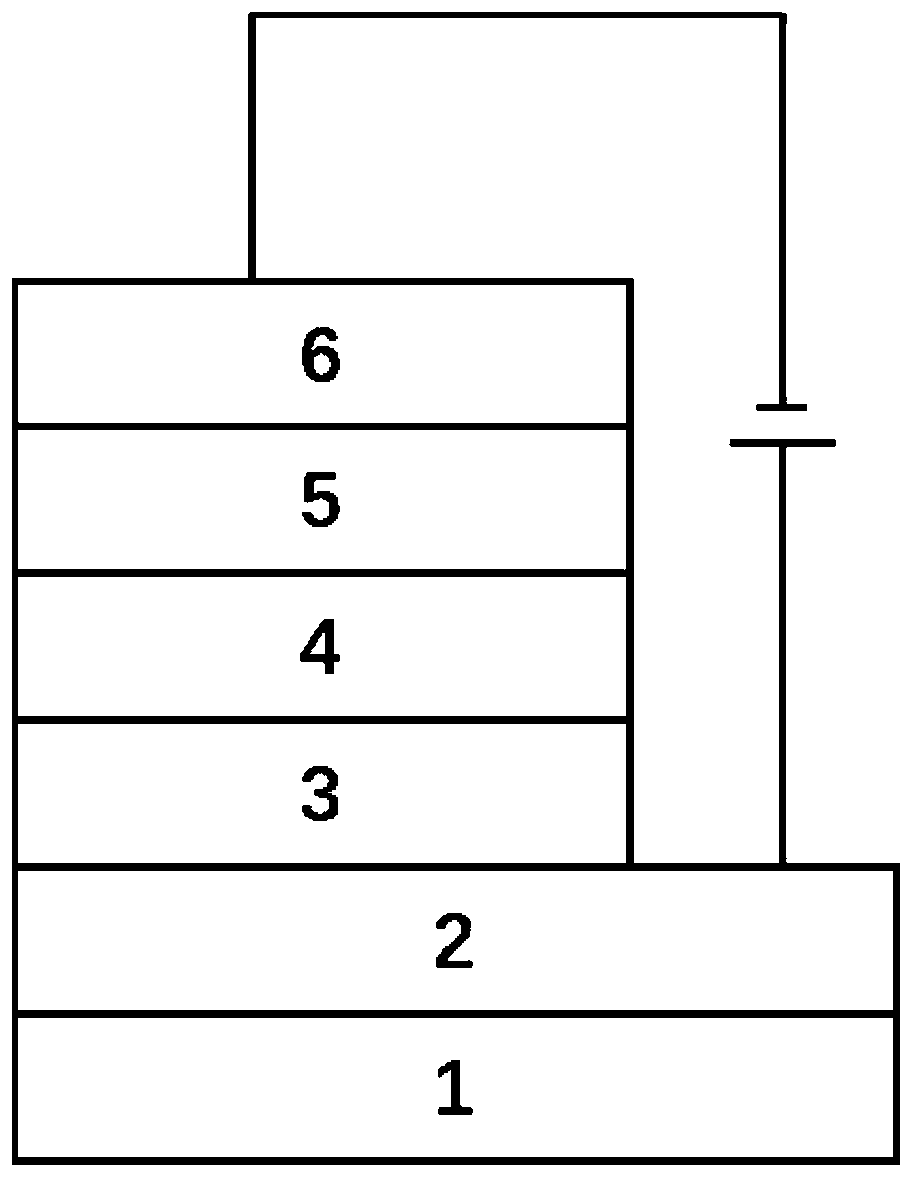

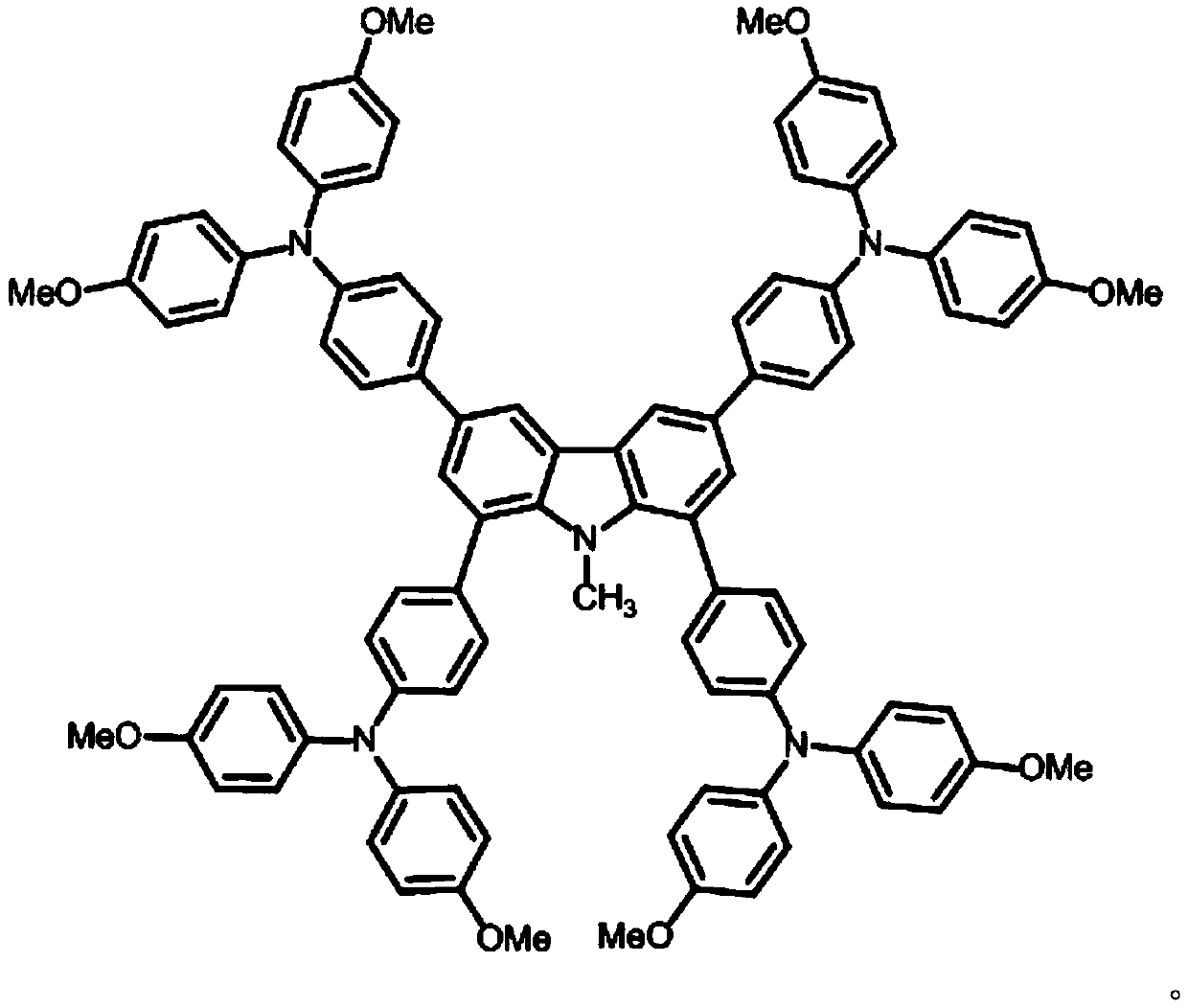

[0048] The substrate composed of the substrate and the transparent conductive anode ITO is cleaned, and dried with nitrogen after cleaning; the surface of the transparent conductive anode ITO is spin-coated with SnO2 (water dispersion, the spin-coating speed is 3000rpm, the spin-coating time is 30s, the thickness 20-30nm) to prepare an electron transport layer, and thermally anneal the formed film (annealing temperature 150°C, annealing time 15min); spin-coat the MAPbI3 precursor solution on the electron transport layer (mixed with DMF as a solvent to form a solute concentration For the mixed solution of 500mg / mL, the spin-coating speed is 4000rpm, the spin-coating time is 30s, and the thickness is 500nm) to prepare the perovskite photoactive layer. Inhibit the disordered crystallization of perovskite, and then anneal at 120°C for 20min; spin-coat Car-4-TPA solution (dissolved in chlorobenzene solution at a concentration of 50mg / ml, without any doping) to prepare the hole tran...

Embodiment 2

[0051] The substrate composed of the substrate and the transparent conductive anode ITO is cleaned, and dried with nitrogen after cleaning; the surface of the transparent conductive anode ITO is spin-coated with SnO2 (water dispersion, the spin-coating speed is 3000rpm, the spin-coating time is 30s, the thickness 20-30nm) to prepare an electron transport layer, and thermally anneal the formed film (annealing temperature 150°C, annealing time 15min); spin-coat the MAPbI3 precursor solution on the electron transport layer (mixed with DMF as a solvent to form a solute concentration For the mixed solution of 500mg / mL, the spin-coating speed is 4000rpm, the spin-coating time is 30s, and the thickness is 500nm) to prepare the perovskite photoactive layer. Inhibit the disordered crystallization of perovskite, and then anneal at 120°C for 20 minutes; spin-coat Car-4-TPA solution (dissolved in chlorobenzene solution at a concentration of 50mg / ml, and mix with Li-TFSI) was used to prepa...

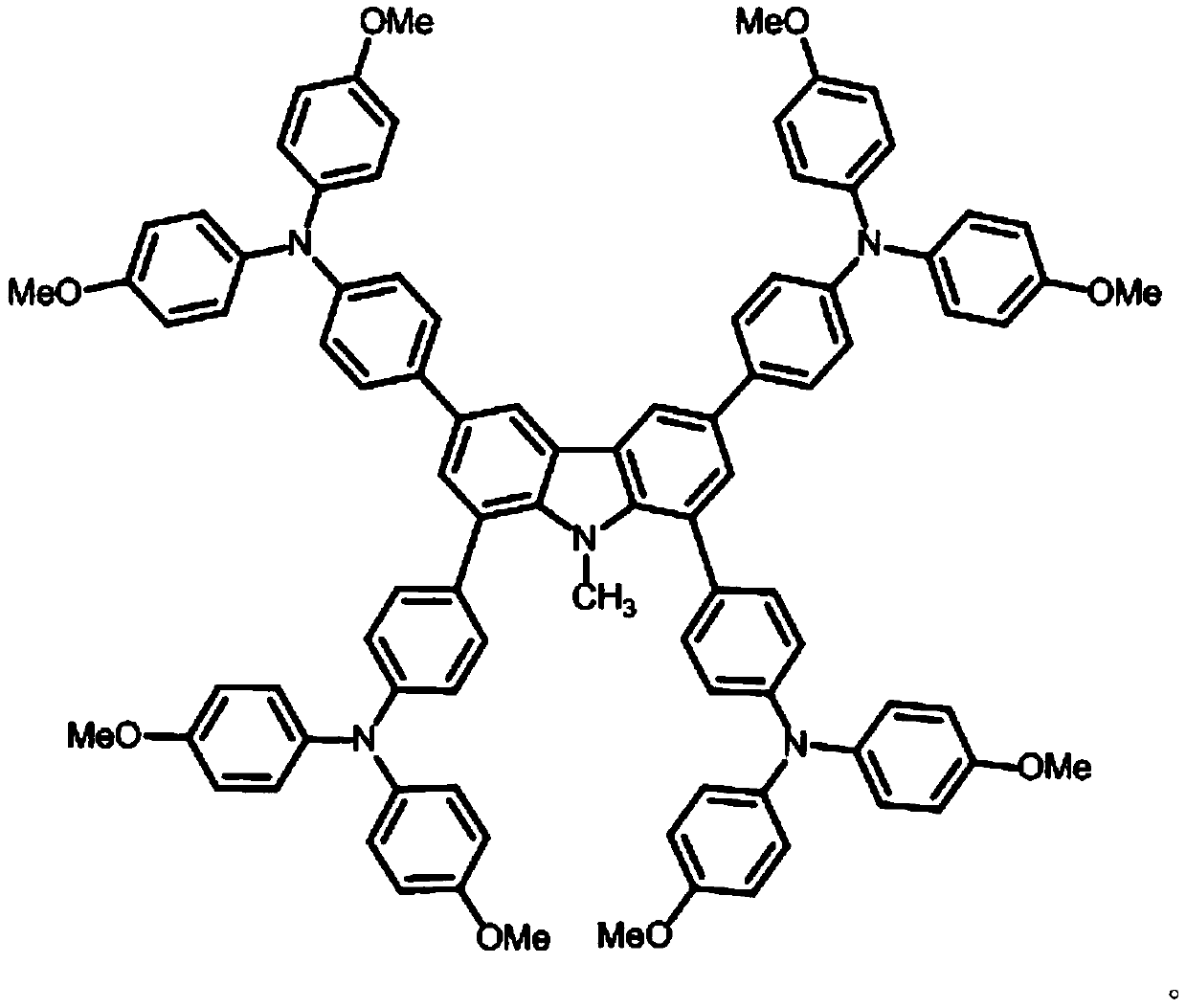

Embodiment 3

[0054] The substrate composed of the substrate and the transparent conductive anode ITO is cleaned, and dried with nitrogen after cleaning; the surface of the transparent conductive anode ITO is spin-coated with SnO2 (water dispersion, the spin-coating speed is 3000rpm, the spin-coating time is 30s, the thickness 20-30nm) to prepare an electron transport layer, and thermally anneal the formed film (annealing temperature 150°C, annealing time 15min); spin-coat the MAPbI3 precursor solution on the electron transport layer (mixed with DMF as a solvent to form a solute concentration For the mixed solution of 500mg / mL, the spin-coating speed is 4000rpm, the spin-coating time is 30s, and the thickness is 500nm) to prepare the perovskite photoactive layer. Inhibit the disordered crystallization of perovskite, and then anneal at 120°C for 20min; spin-coat DNT-4TPA solution (dissolved in chlorobenzene solution at a concentration of 50mg / ml, and doped with Li -TFSI and FK209) to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com