Production method of IPN structure acrylic sanitary appliance composite material

A composite material and production method technology, applied in the direction of coating, etc., can solve the problems of broken polyester resin and fiber bonding, surface coating damage, high noise, etc., and achieve good processing fluidity and low hygroscopicity, thermal deformation Increased temperature and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

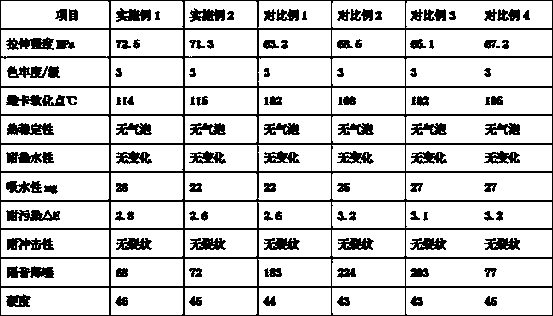

Embodiment 1

[0022] The first step is to prepare and weigh the following raw materials in corresponding parts by weight for subsequent use:

[0023]Liquid A: 70 parts of methyl methacrylate, 0.5 parts of initiator B, 8 parts of organically modified calcium sulfate whiskers; Liquid B: 30 parts of vinyl ester resin, 20 parts of styrene, diethylene glycol diallyl 8 parts of carbonate, 0.1 part of initiator A, 2 parts of crosslinking agent; the second step, mix A liquid and B liquid evenly, under the protection of nitrogen, pour into a closed stirring tank at 65 °C and stir for 15 minutes After that, heat up to 90°C and continue to stir for 30 minutes to carry out the polymerization reaction. After that, it is transferred to the resin impregnation tank. The process time is 1.5 minutes, the treatment temperature is 75°C, and the amount of impregnation is controlled. The forming mold adopts a three-stage gradient heating method, and the temperature range is 105°C, 115°C, and 120°C in sequence, a...

Embodiment 2

[0025] The first step is to prepare and weigh the following raw materials in corresponding parts by weight for subsequent use:

[0026] Liquid A: 60 parts of methyl methacrylate, 0.1 part of initiator B, 6 parts of organically modified calcium sulfate whiskers; Liquid B: 20 parts of vinyl ester resin, 18 parts of styrene, diethylene glycol diallyl 5 parts of carbonate, 0.05 parts of initiator A, 1 part of cross-linking agent; the second step, mix A liquid and B liquid evenly, under the protection of nitrogen, pour into a closed stirring tank at 65 °C and stir for 10 minutes After that, heat up to 90°C and continue to stir for 20 minutes to carry out the polymerization reaction. After that, it is transferred to the resin impregnation tank. The process time is 1 minute, the treatment temperature is 60°C, and the amount of impregnation is controlled. The forming mold adopts a three-stage gradient heating method, and the temperature range is 115°C, 120°C, and 125°C in sequence, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com