Preparation method of phenylallyl hydroxamic acid/acrylamide/methyl methacrylate copolymer for ore flotation

A technology of methyl methacrylate and phenylpropenyl hydroxamic acid, which is applied in the field of polymer chemical polymerization, can solve the problems of inability to achieve maximum income and low product yield, and achieve low mineral processing cost, low dosage, The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

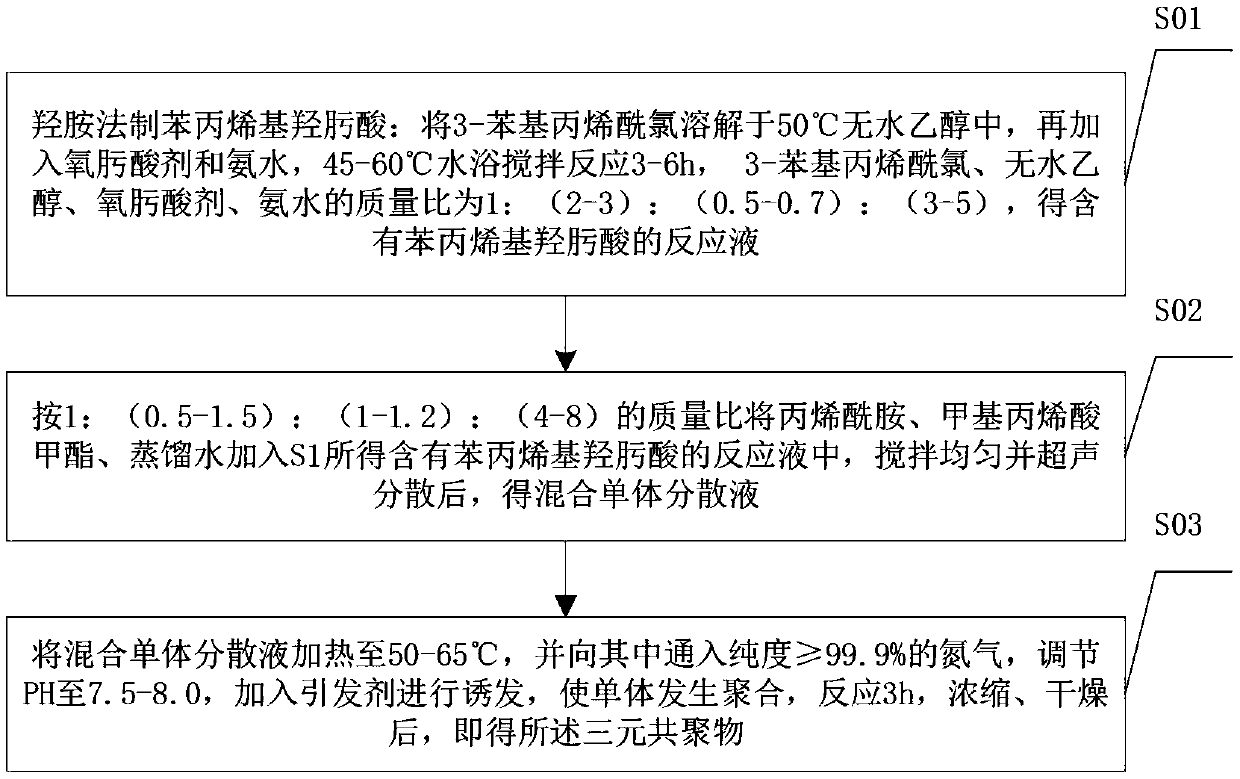

[0023] A kind of preparation method of phenylpropenyl hydroxamic acid / acrylamide / methyl methacrylate copolymer for ore flotation, comprises the following steps:

[0024] S1: Preparation of phenylpropenyl hydroxamic acid by hydroxylamine method: Dissolve 3-phenylacryloyl chloride in absolute ethanol at 50°C, then add hydroxamic acid agent and 25% ammonia water, stir in a water bath at 45°C for 3 hours, 3- The mass ratio of phenylacryloyl chloride, absolute ethanol, hydroxylamine hydrochloride, and ammonia water is 1:2:0.5:3 to obtain a reaction solution containing phenylacryl hydroxamic acid;

[0025] S2: According to the mass ratio of 1:0.5:1:4, add acrylamide, methyl methacrylate, and distilled water to the reaction solution containing phenylpropenyl hydroxamic acid obtained in S1, stir evenly and ultrasonically disperse to obtain a mixed monomer Dispersions;

[0026] S3: Heat the mixed monomer dispersion to 50°C, and pass nitrogen gas with a purity ≥ 99.9% into it, adjust t...

Embodiment 2

[0028] A kind of preparation method of phenylpropenyl hydroxamic acid / acrylamide / methyl methacrylate copolymer for ore flotation, comprises the following steps:

[0029] S1: Preparation of phenylpropenyl hydroxamic acid by hydroxylamine method: Dissolve 3-phenylacryloyl chloride in absolute ethanol at 50°C, then add hydroxamic acid agent and ammonia water with a concentration of 28%. The hydroxamic acid agent is hydroxylamine sulfate, A mixture of equal masses of hydroxylamine hydrochloride was stirred and reacted in a water bath at 55°C for 4.5 hours. The mass ratio of 3-phenylacryloyl chloride, absolute ethanol, hydroxamic acid agent, and ammonia water was 1:2.5:0.6:4, and the mixture containing phenylpropenyl hydroxyl The reaction solution of oxamic acid;

[0030] S2: Add acrylamide, methyl methacrylate, and distilled water into the reaction solution containing phenylpropenylhydroxamic acid obtained in S1 at a mass ratio of 1:1:1.1:6, stir evenly and ultrasonically disperse...

Embodiment 3

[0033] A kind of preparation method of phenylpropenyl hydroxamic acid / acrylamide / methyl methacrylate copolymer for ore flotation, comprises the following steps:

[0034] S1: Preparation of phenylpropenylhydroxamic acid by the hydroxylamine method: Dissolve 3-phenylacryloyl chloride in absolute ethanol at 60°C, then add hydroxylamine sulfate and 30% ammonia water, stir in a water bath at 60°C for 6 hours, 3-phenyl The mass ratio of acryloyl chloride, absolute ethanol, hydroxylamine sulfate, and ammonia water is 1:3:0.7:5 to obtain a reaction solution containing phenylpropenyl hydroxamic acid;

[0035] S2: According to the mass ratio of 1:1.5:1.2:8, add acrylamide, methyl methacrylate, and distilled water to the reaction solution containing phenylpropenylhydroxamic acid obtained in S1, stir evenly and ultrasonically disperse to obtain a mixed monomer Dispersions;

[0036] S3: Heat the mixed monomer dispersion to 65°C, and pass nitrogen gas with a purity ≥99.9% into it, adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com