Livestock and poultry manure composite sulfuric acid type furfural residue organic fertilizer and preparation method thereof

A furfural slag and sulfuric acid type technology, applied in the field of breeding, can solve the problems of long time, long decomposition time, soil acidification, etc., and achieve the effect of increasing the fermentation rate, improving air quality, and increasing organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

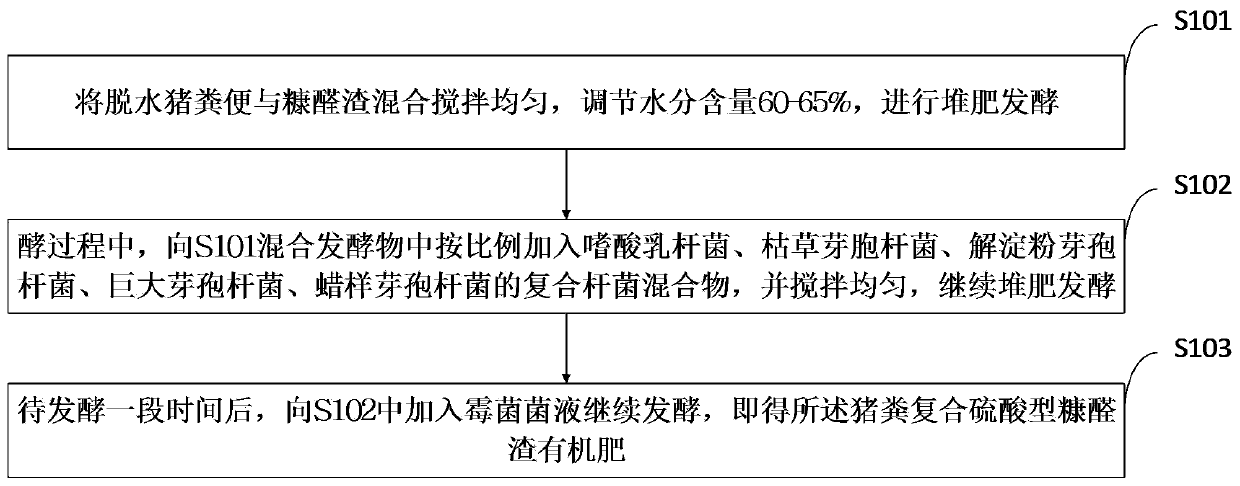

[0038] The invention provides a method for preparing livestock and poultry manure compound sulfuric acid furfural slag organic fertilizer, comprising:

[0039] Step 1: Mix and stir the dehydrated livestock and poultry manure and furfural slag evenly, adjust the water content to 60-65%, and carry out composting and fermentation.

[0040] Step 2: During the fermentation process, add the compound bacteria mixture of Lactobacillus acidophilus, Bacillus subtilis, Bacillus amyloliquefaciens, Bacillus megaterium, and Bacillus cereus in proportion to the mixed fermented product of step 1, stir evenly, and continue composting fermentation.

[0041] Step 3: after fermenting for a period of time (determining the fermentation time according to the actual situation), add mold liquid to step 2 to continue fermentation, and obtain the livestock and poultry manure compound sulfuric acid furfural slag organic fertilizer.

[0042] In the first step, the pH of the composting fermentation of liv...

Embodiment 1

[0053] The pig manure composite sulfuric acid type furfural slag organic fertilizer provided by the invention consists of 400 parts of pig manure, 300 parts of furfural slag, 2 parts of Lactobacillus acidophilus bacterial liquid, 2 parts of Bacillus subtilis, 2 parts of Bacillus megaterium, and Bacillus cereus 1 serving consists.

[0054] The complex bacteria are composed of Lactobacillus acidophilus, Bacillus subtilis, Bacillus megaterium and Bacillus cereus.

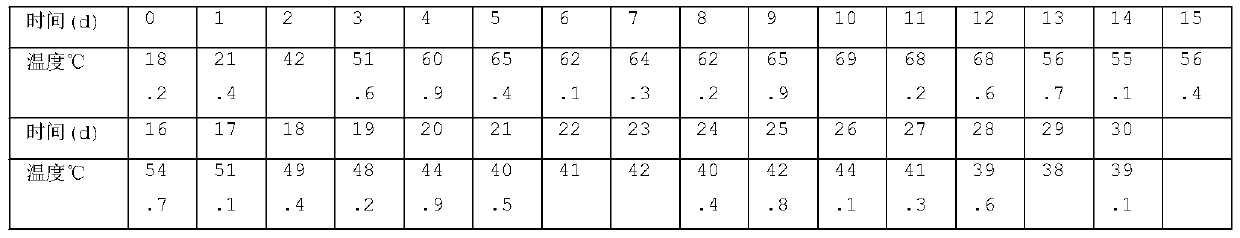

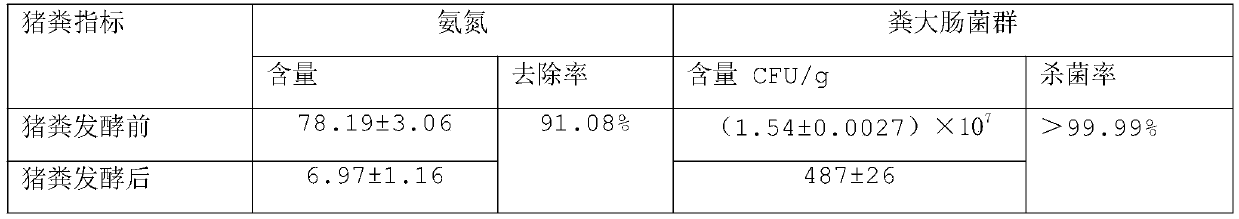

[0055] After the fifth day of fermentation, the temperature exceeds 65°C, and after 30 days of fermentation, the temperature drops below 40°C. At this time, the water content of the mixed material is 34%, the pH is 6.8, the total content of nitrogen, phosphorus, and potassium is >7, the organic matter content is 74, and the color of the fermented material is light brown. The removal rate of ammonia nitrogen exceeds 90%, and the killing rate of E. coli exceeds 99.99%, which can be directly used in the production of powd...

Embodiment 2

[0057] The livestock and poultry manure compound sulfuric acid type furfural slag organic fertilizer provided by the invention, the pig manure compound sulfuric acid type furfural slag organic fertilizer is composed of 600 parts of pig manure, 500 parts of furfural slag, 5 parts of Lactobacillus acidophilus bacterial liquid, 4 parts of Bacillus subtilis 3 parts of Bacillus amyloliquefaciens, 5 parts of Bacillus megaterium, 3 parts of Bacillus cereus and 2 parts of mold liquid.

[0058] The composite bacteria consist of Lactobacillus acidophilus, Bacillus subtilis, Bacillus amyloliquefaciens (CGMCC No. 10011), Bacillus megaterium and Bacillus cereus.

[0059] After the fifth day of fermentation, the temperature exceeds 65°C, and after 30 days of fermentation, the temperature drops below 40°C. At this time, the moisture content of the mixed material is about 35%, the pH is 6.4, the total content of nitrogen, phosphorus, and potassium is >7, the organic matter content is 68, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com