Cobalt-free power battery positive electrode material as well as preparation method and application thereof

A power battery and positive electrode material technology, which is applied in the field of cobalt-free power battery positive electrode materials and its preparation, can solve the problems that restrict the expansion of nickel-cobalt-lithium manganese oxide, magnetic foreign matter is easy to exceed the standard, and the process control is difficult, so as to avoid particle surface Effects of cracking, low cost, and shortened sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

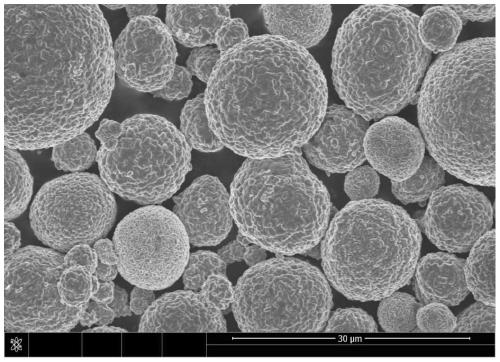

Image

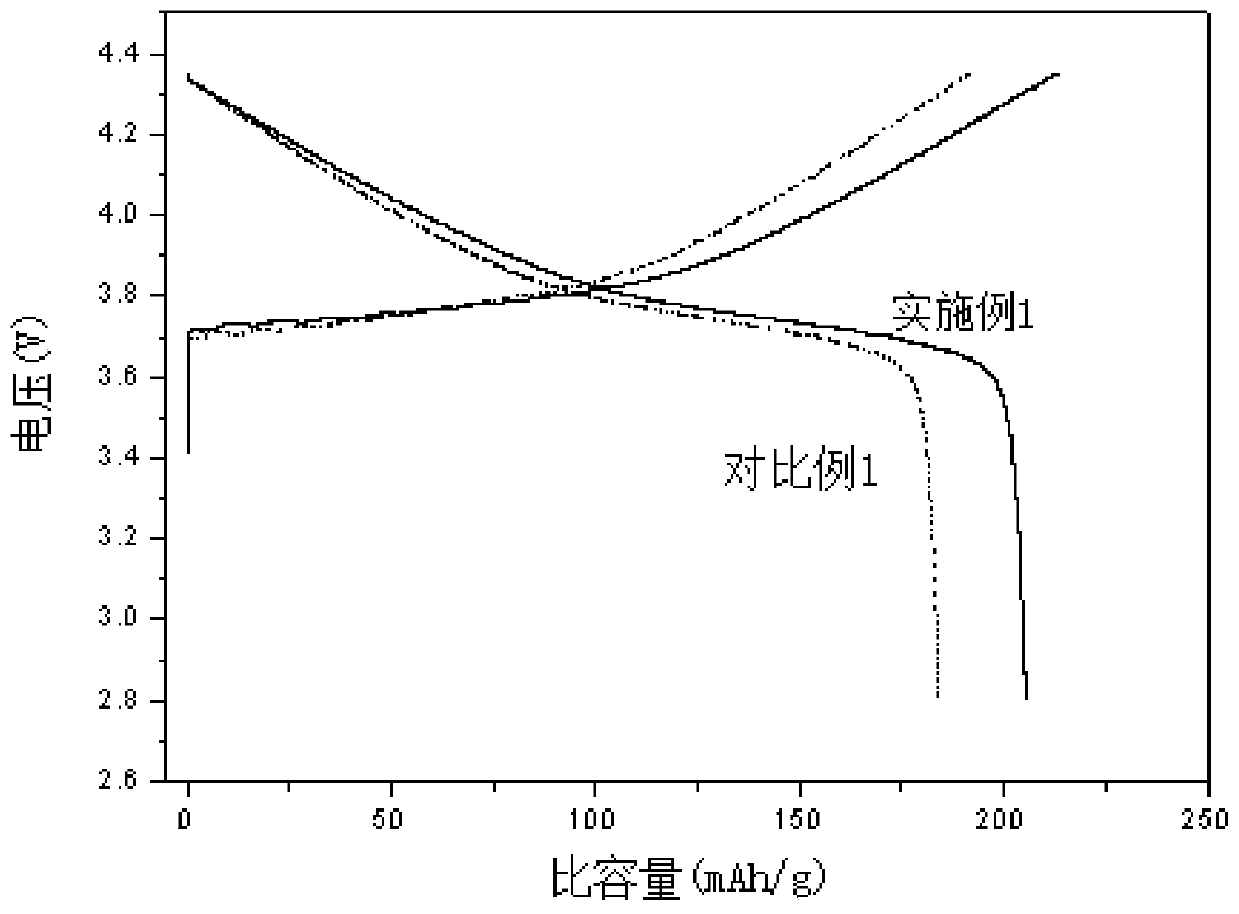

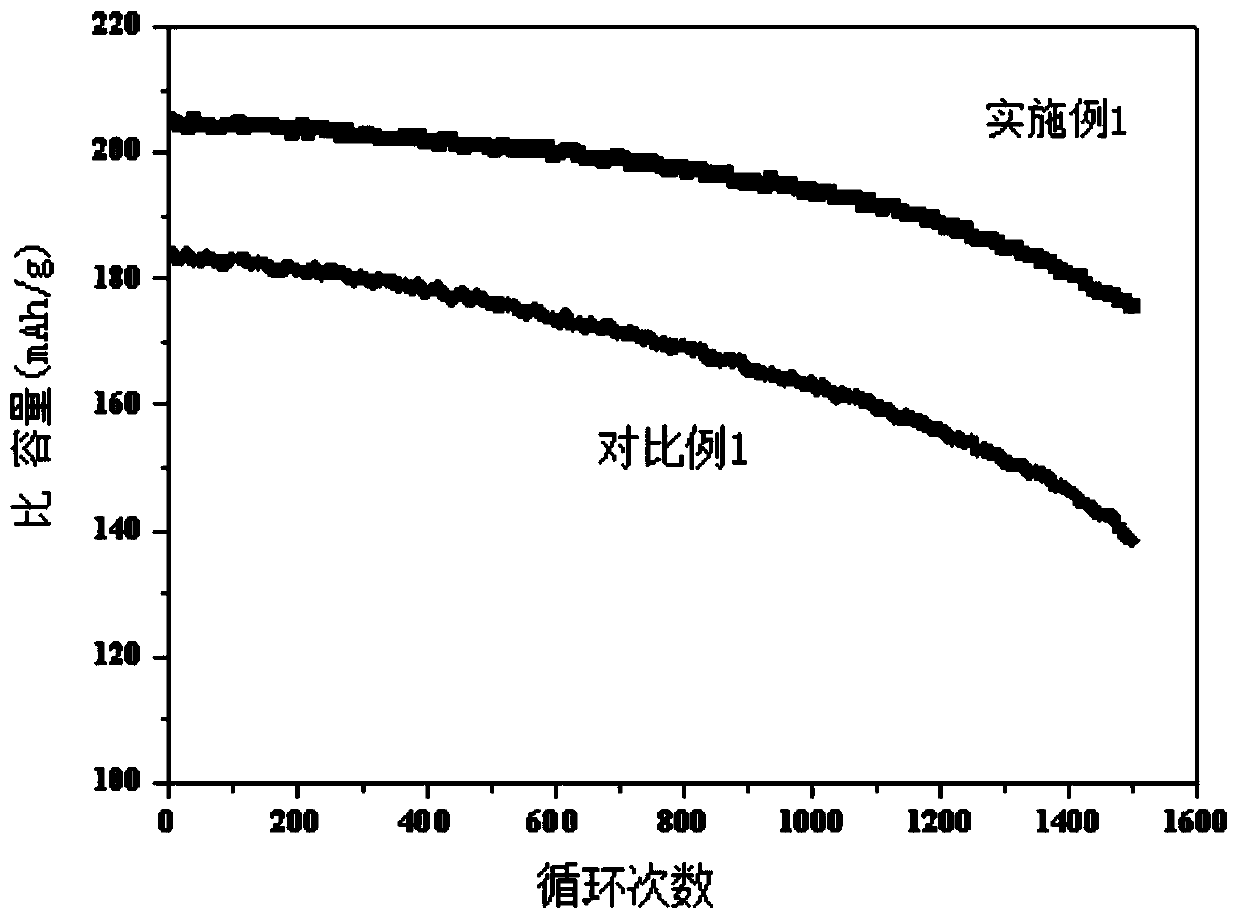

Examples

Embodiment 1

[0075] The preparation method of the cobalt-free power battery positive electrode material in this embodiment includes the following specific steps:

[0076] (1) Mix nickel-manganese hydroxide (the molar ratio of nickel and manganese elements is 90:10) and lithium carbonate in a molar ratio of 1:1.0, add tricobalt tetroxide at 0.05%, and add water at a solid-to-liquid ratio of 1:0.2, High energy ball milling (the ratio of ball to material is 5:1, the rotational speed of the ball mill is 1200rpm, and the milling time is 1h), stirring at 60°C to obtain the slime A;

[0077] (2) Lubricate the inner wall of the mold cavity with lithium-based grease, put the sludge A into the mold, apply a preload of 1MPa, heat from room temperature to 160°C at 0.2°C / min, and keep the temperature constant for 1h;

[0078] (3) The mixed powder is subjected to high-energy pressing, the pressing speed is 5m / s, the ratio of pressing energy to powder loading is 800:8g, and a green compact is obtained; ...

Embodiment 2

[0086] The preparation method of the cobalt-free power battery positive electrode material in this embodiment comprises the following steps:

[0087] (1) Mix nickel-manganese hydroxide (where the molar ratio of nickel and manganese is 65:35) and lithium hydroxide in a molar ratio of 1:1.2, add magnesium oxide at 1%, and add ethanol at a solid-to-liquid ratio of 1:0.6 , high-energy ball milling (ball-to-material ratio 25:1, ball mill speed 800rpm, ball milling time 5h), stirring at 95°C to obtain a slime;

[0088] (2) Use lithium-based grease to lubricate the inner wall of the mold cavity, put the mud into the mold, apply a 5MPa preload, heat from room temperature to 100°C at 3°C / min, and keep the temperature for 3h to obtain a mixed powder;

[0089] (3) The mixed powder is subjected to high-energy pressing, the pressing speed is 17m / s, the ratio of pressing energy to powder loading is 2500J: 30g, and a green compact is obtained;

[0090] (4) Heat the compact to 1000°C in an o...

Embodiment 3

[0096] The preparation method of the cobalt-free power battery positive electrode material in this embodiment comprises the following steps:

[0097] (1) Mix nickel-manganese hydroxide (the molar ratio of nickel and manganese elements is 25:75) and lithium hydroxide in a molar ratio of 1:1.1, add cerium citrate at 3%, and add at a solid-to-liquid ratio of 1:0.4 Acetone, high-energy ball milling (ball-to-material ratio 10:1, ball mill speed 1000rpm, ball milling time 3h), stirring at 80°C to obtain a sludge;

[0098] (2) Use lithium base grease to lubricate the inner wall of the mold cavity, put the mud into the mold, apply 3MPa preload, heat from room temperature to 130°C at 3°C / min, and keep the temperature for 2h to obtain the mixed powder;

[0099] (3) The mixed powder is subjected to high-energy pressing, the pressing speed is 10m / s, the ratio of pressing energy to powder loading is 1500J: 15g, and a green compact is obtained;

[0100] (4) Heat the compact to 800°C in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com